Multi-station workbench of forging press for rod-shaped forging piece

A workbench and forging press technology, applied in forging presses, forging presses, forging/pressing/hammering machinery, etc., can solve the problems of low work efficiency, cumbersome procedures, and high labor intensity, so as to improve work efficiency, automation, The effect of reducing labor intensity and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

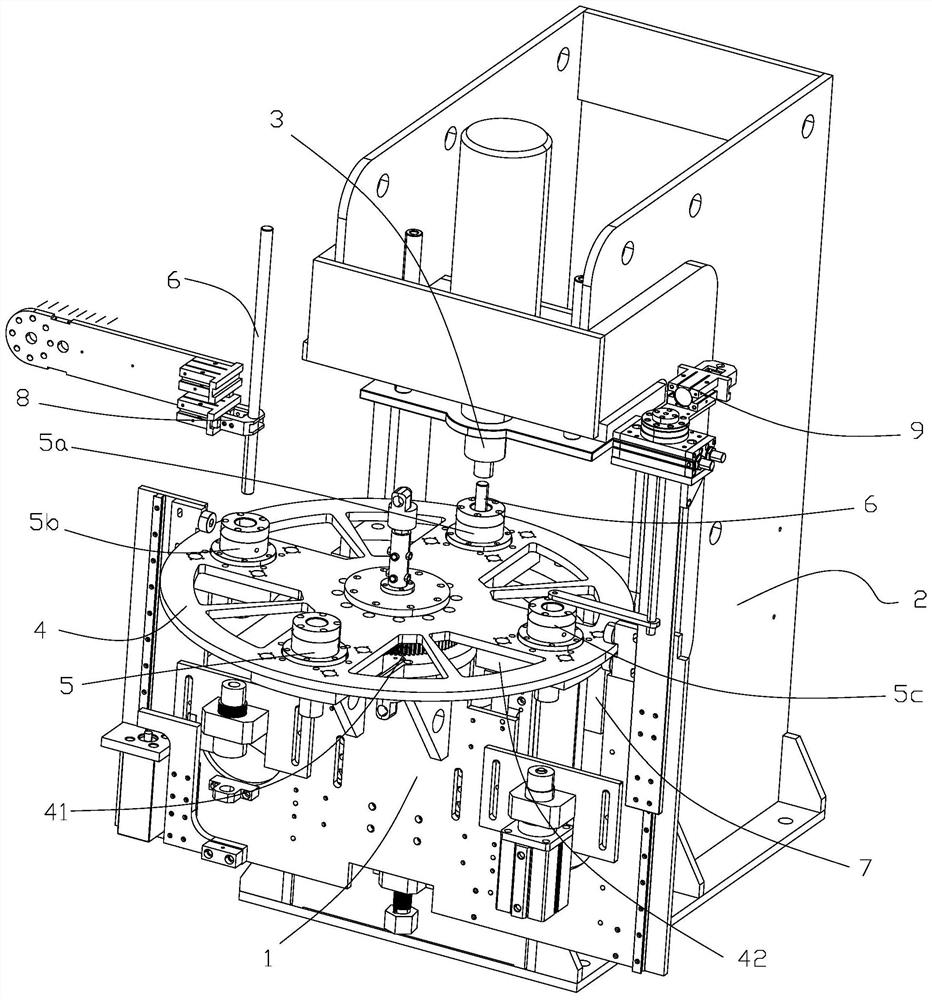

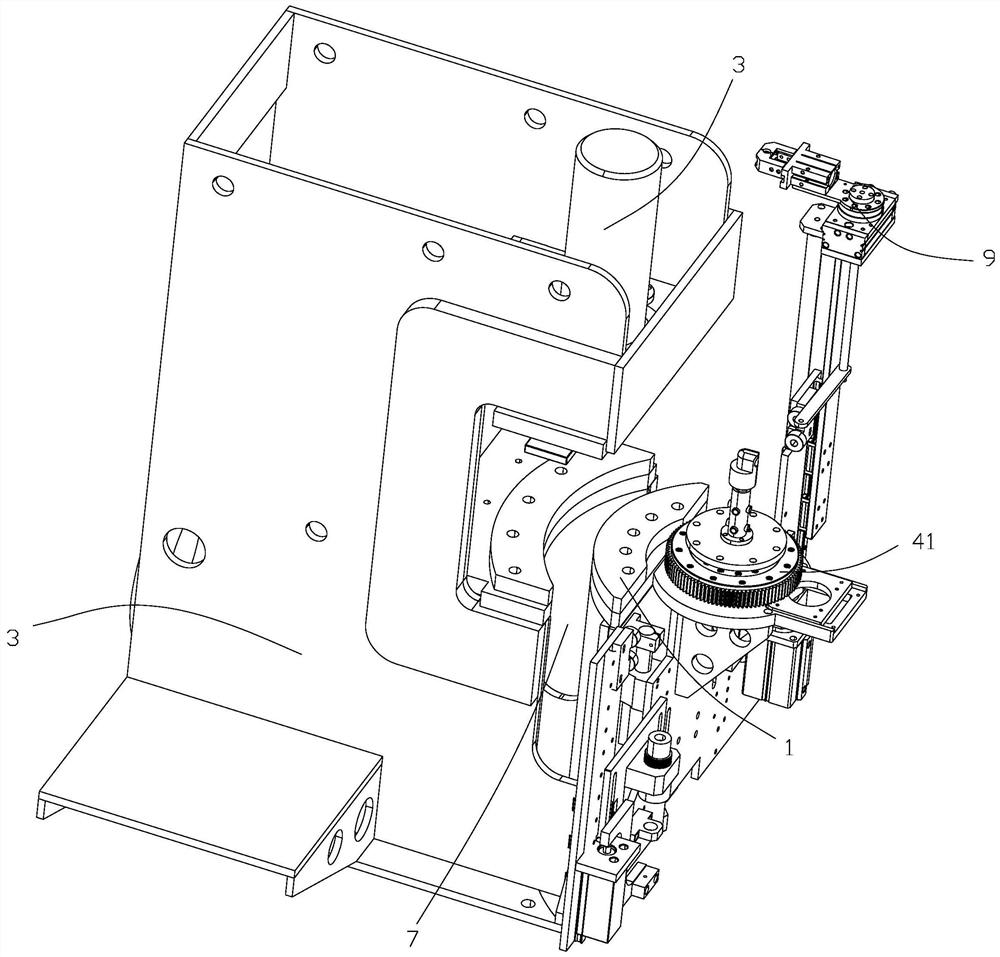

[0013] Such as figure 1 with 2 As shown, a multi-station workbench of a rod-shaped forging press includes a workbench 1 and a headstock 2, and the headstock 2 is provided with a forging head 3 above the workbench 1.

[0014] A turntable 4 for intermittent rotation is installed on the workbench 1, and at least three forging dies 5 are arranged at equal intervals along the circumference of the outer circle of the turntable 4, so that each forging die can be used for simultaneously performing rod-shaped forging. Parts of the material, forging and blanking operations. In this illustration, four forging dies 5 are set, but in practice, three or more can be set as required.

[0015] The bottom of the turntable 4 is coaxially provided with a rotating toothed disc 41, and the rotating toothed disc 41 is driven by a driving motor to work. The angle that rotating disk 4 rotates at every turn is 360 ° / number of forging dies, because the forging die 5 that is provided with is four in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com