Uniform cooling device for aluminum ingots

A technology of uniform cooling and aluminum ingots, which is applied in the field of cooling devices, can solve the problems of low utilization rate of aluminum ingots and uneven cooling of aluminum ingots, and achieve the effects of avoiding uneven cooling, good cooling treatment, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

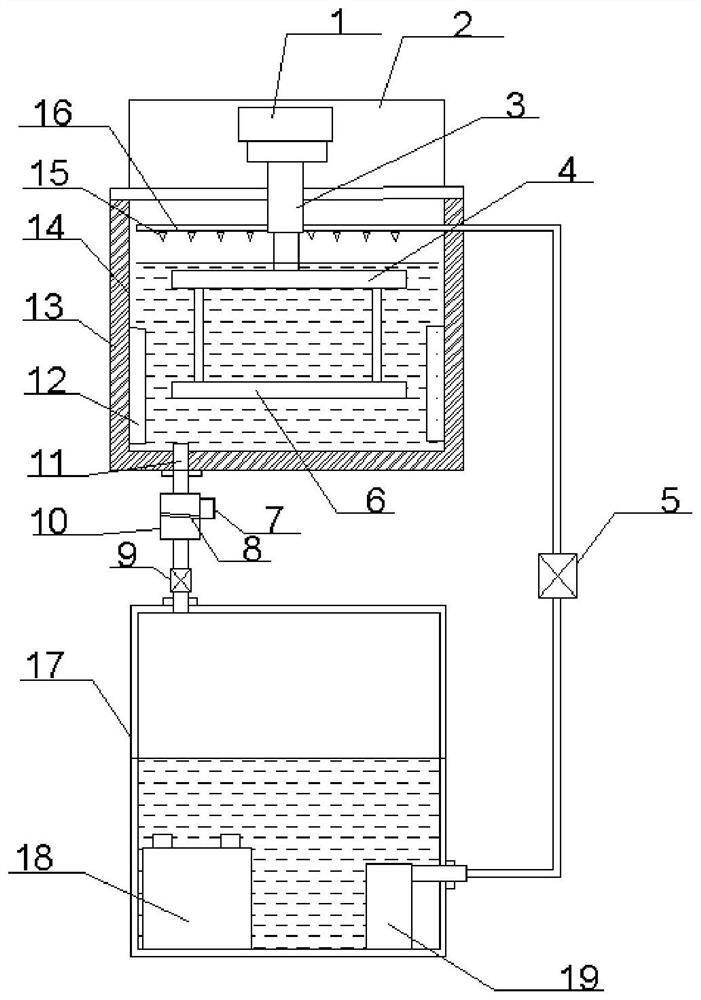

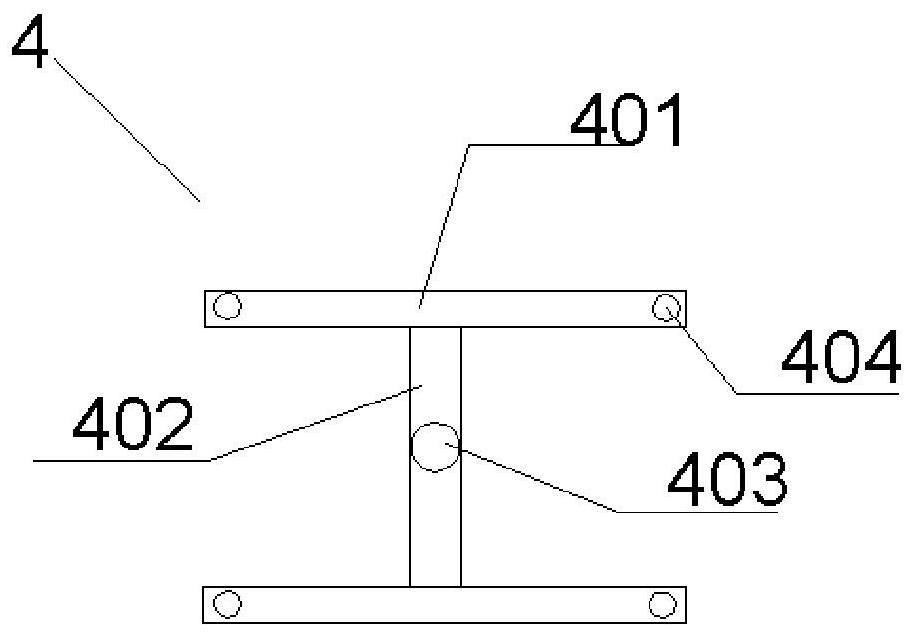

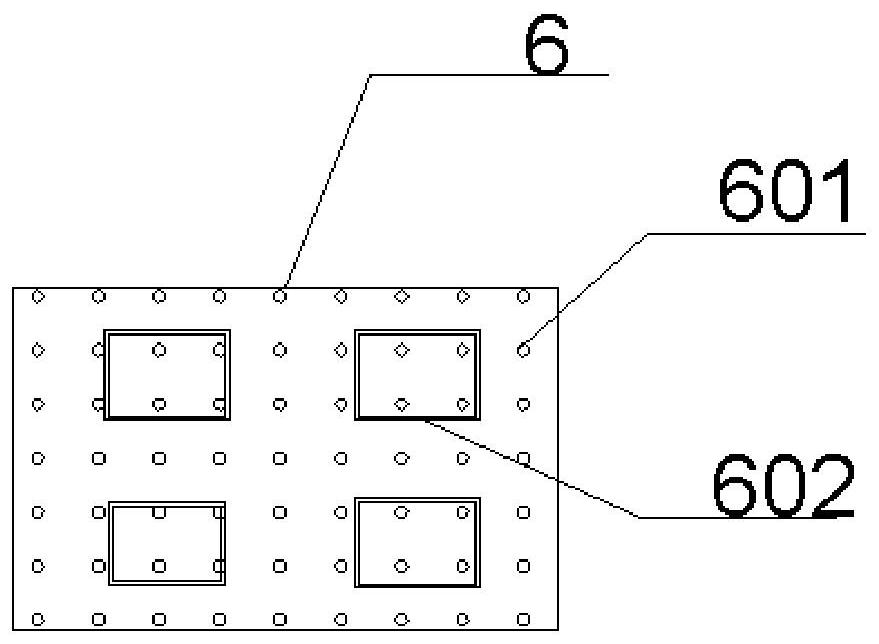

[0026] In order to solve the problem that the uneven temperature cooling of aluminum ingots affects the quality of aluminum ingots and the low utilization rate of water, the present invention provides a uniform cooling device for aluminum ingots, including a cooling movable box 14, which is arranged in the cooling movable box 14 below the water storage tank 17, the cooling movable tank 14 communicates with the water storage tank 17 through the water outlet pipe 11 and the water inlet pipe 16, and the fixed frame assembly 4 and the frame used in conjunction with the fixed frame assembly 4 are arranged in the cooling movable box 14 Base 6, a motor fixing box 2 is arranged above the cooling movable box 14, and a telescopic rotating motor 1 is arranged in the motor fixing box 2, and the model of the telescopic rotating motor is ZF-10, and the telescopic rotating motor 1 The output end of the output end is connected with the telescopic rod 3, and the telescopic rod 3 is fixedly conn...

Embodiment 2

[0032] On the basis of Embodiment 1, in order to further reduce the temperature of the aluminum ingot evenly, the water inlet pipe 16 enters the inside of the cooling movable box 14 from the upper part of the cooling movable box 14, and the water outlet pipe 11 is arranged at the bottom of the cooling movable box 14. At the bottom, the water inlet pipe 16 is provided with a valve A5, and the water outlet pipe 11 is provided with a valve B9. The cooling water flows down from the top of the aluminum ingot, further avoiding the problem of uneven cooling.

Embodiment 3

[0034] On the basis of Example 1, in order to collect and process the debris generated when the aluminum ingot is cooled, a filter device is provided on the outlet pipe 11, and the filter device includes a filter housing 10, and is arranged on a filter The filter screen 8 in the housing 10. Avoid the impact of debris on cooling water and aluminum ingots.

[0035] Further, the filter screen 8 is arranged obliquely in the filter housing 10 , and a slag storage tank 7 is provided on the lower end side of the filter screen 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com