Rotary base capable of automatically returning to original point

A rotating base, automatic return technology, applied in the direction of clamps, workpiece clamping devices, shafts, etc., can solve problems such as breakage, bending, easy damage or deformation of the cover, and achieve the effect of preventing damage or accidents and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

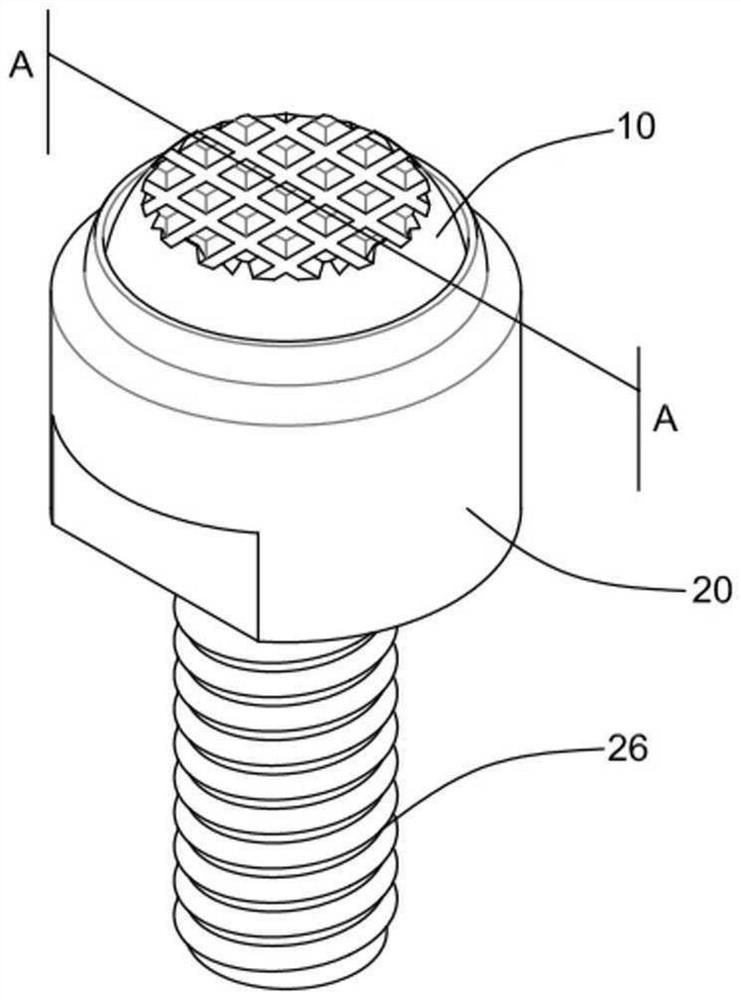

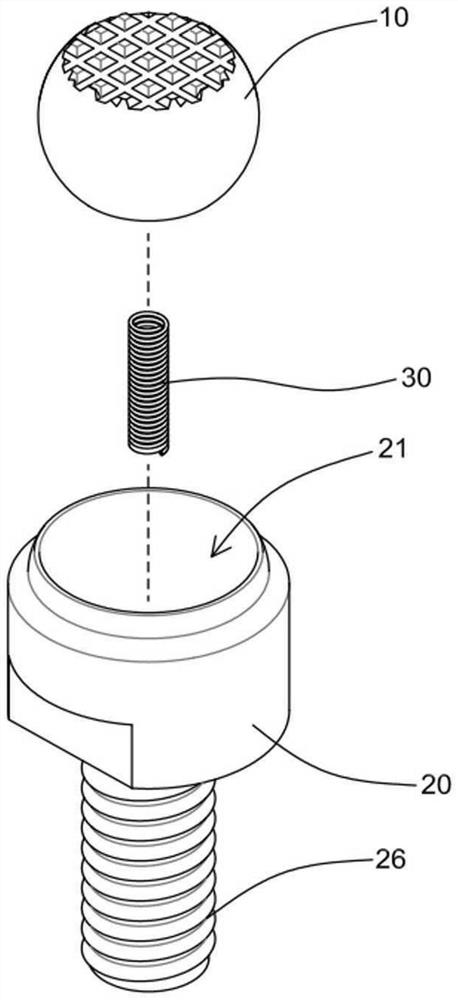

[0076] Hereinafter, an embodiment of the present invention will be described in more detail with reference to the drawings.

[0077] As a reference, the description with reference to the accompanying drawings is for easier understanding of the present invention, rather than limiting the scope of the present invention by them. In addition, when describing the present invention, when it is judged that the specific description of related known technologies is unnecessary and obscures the gist of the present invention, the specific description will be omitted.

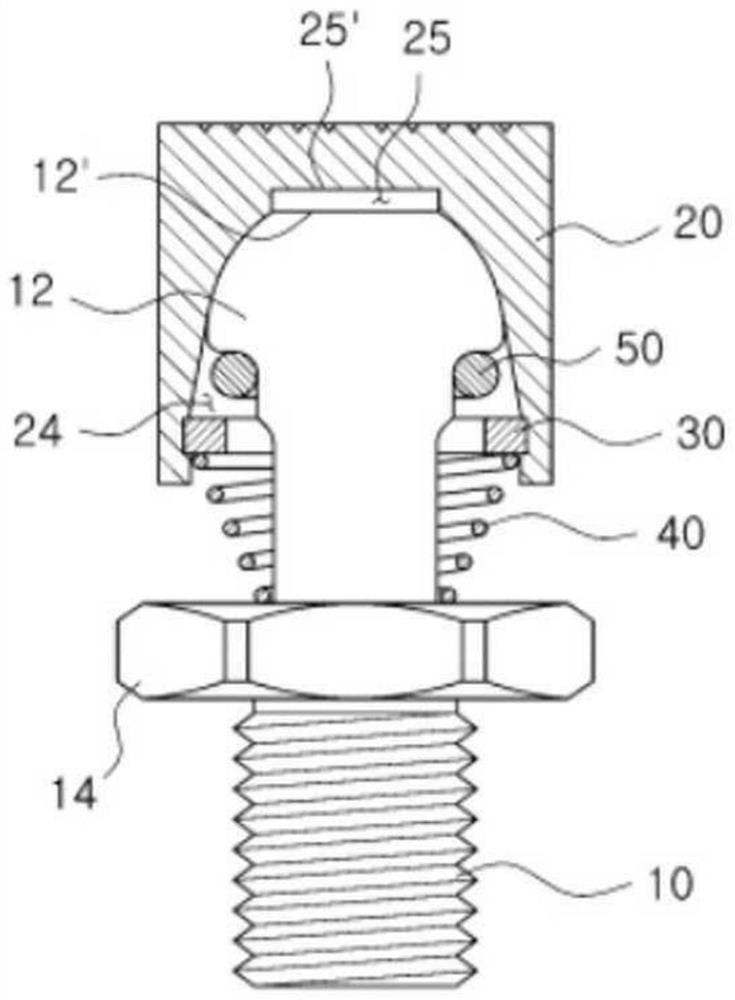

[0078] figure 1 To show a section view of the swivel base showing the existing homing.

[0079] The invention relates to a rotating base used for fixing or moving mechanical products and being connected with one side of a fixture, and the upper surface of a compression ball is compressed with the surface of the mechanical products to fix the mechanical products.

[0080] Specifically, it relates to a case where the shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com