Resource recycling organic matter wet garbage power generation end pretreatment system

A waste-to-energy and pretreatment technology, which is applied in the directions of packaging, unsealing of packaged objects, cutting and unsealing, etc., can solve the problems of physical and mental health injuries of staff, reduce production efficiency, kitchen waste, and cannot guarantee the personal safety of staff, etc. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

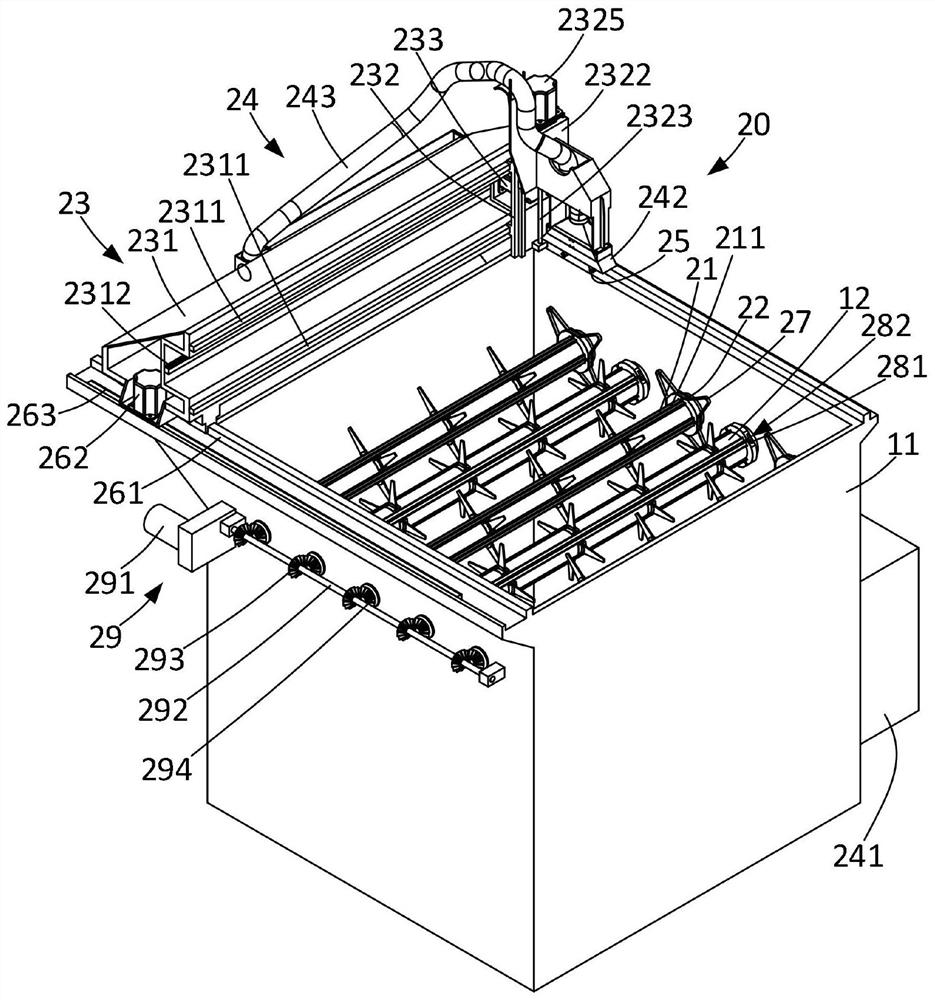

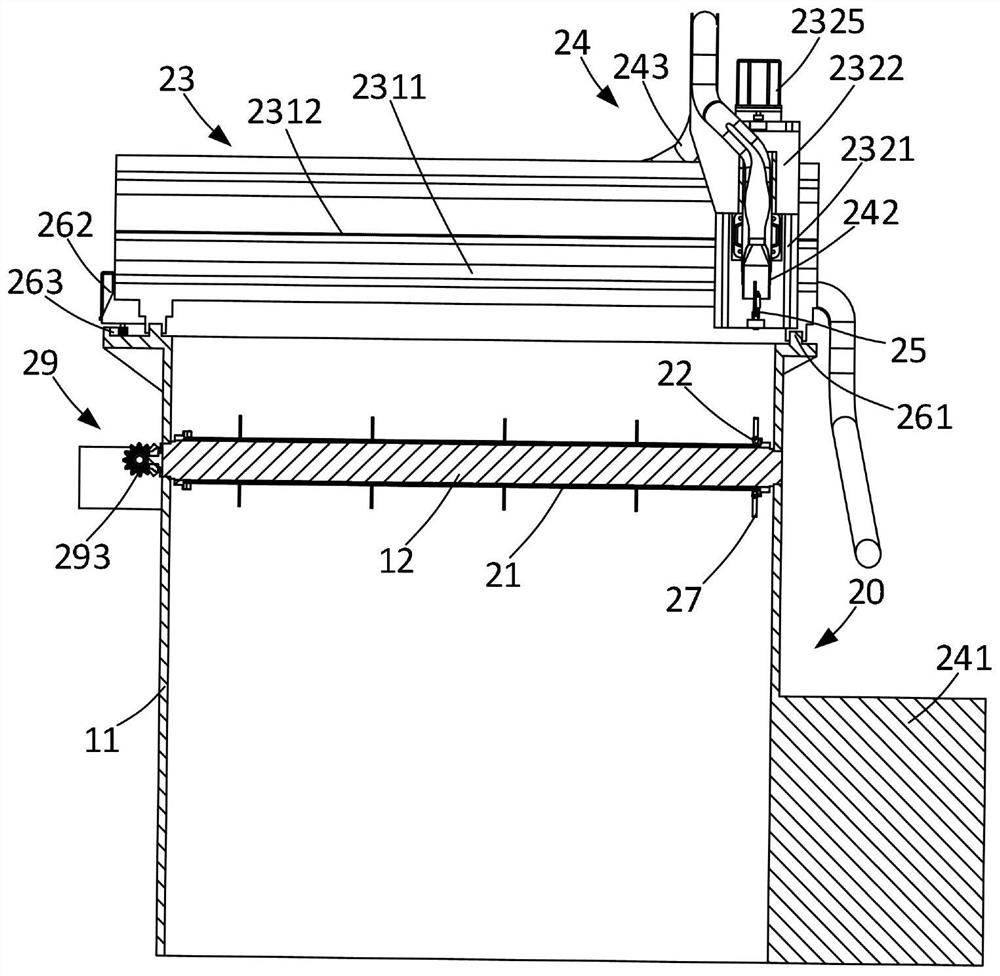

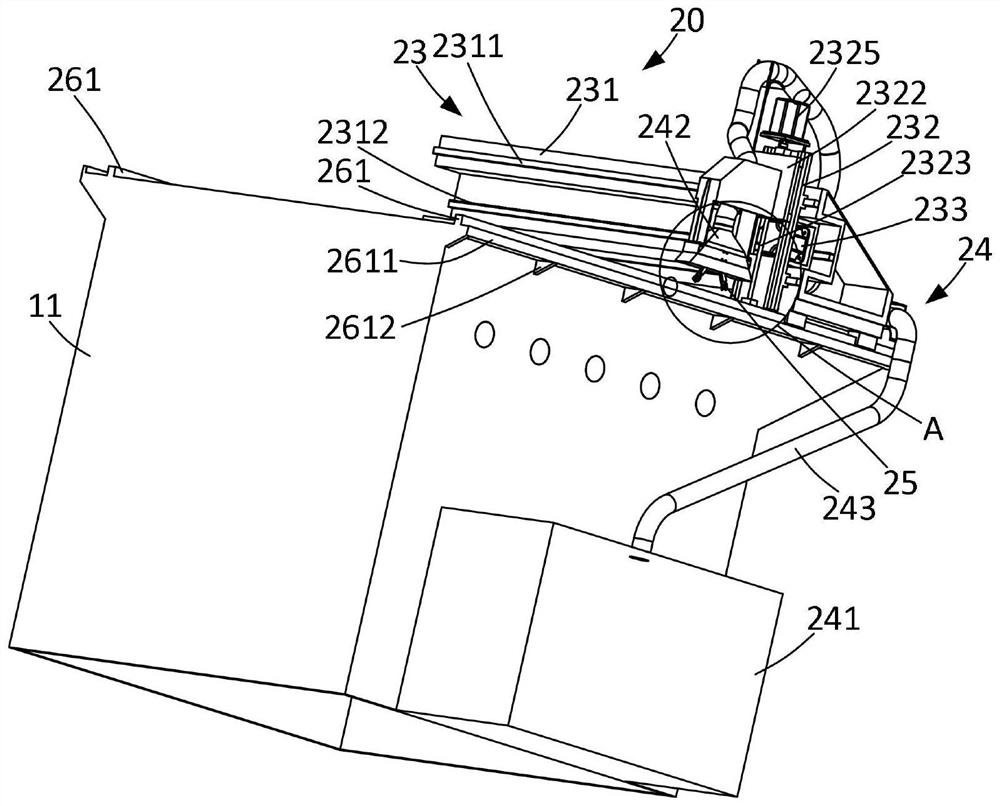

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0042] refer to figure 1 , the present invention provides a resource reuse organic matter wet waste power generation terminal pretreatment system, which can realize automatic cleaning of plastic bags wrapped on the cutter shaft, realize online automatic cleaning of plastic bags without stopping the machine, save labor costs, and avoid human The work can also guarantee the personal safety of the staff and avoid the occurrence of harm to the physical and mental health of the staff caused by the sour and odorous gas of kitchen waste. The pretreatment system does not need to be shut down during cleaning, and the efficiency is high, which can improve the treatment of wet garbage. efficiency. In addition, the terminal pretreatment system of resource reuse organic matter wet waste power generation terminal pretreatment system of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com