Vertical metal sound barrier unit plate

A sound barrier, vertical technology, applied in the direction of construction, noise absorption devices, etc., can solve the problems of increased load, impact on sound absorption effect and life, increase of cotton bulk density, etc., to prevent the increase of cotton bulk density, improve the sound absorption effect and The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

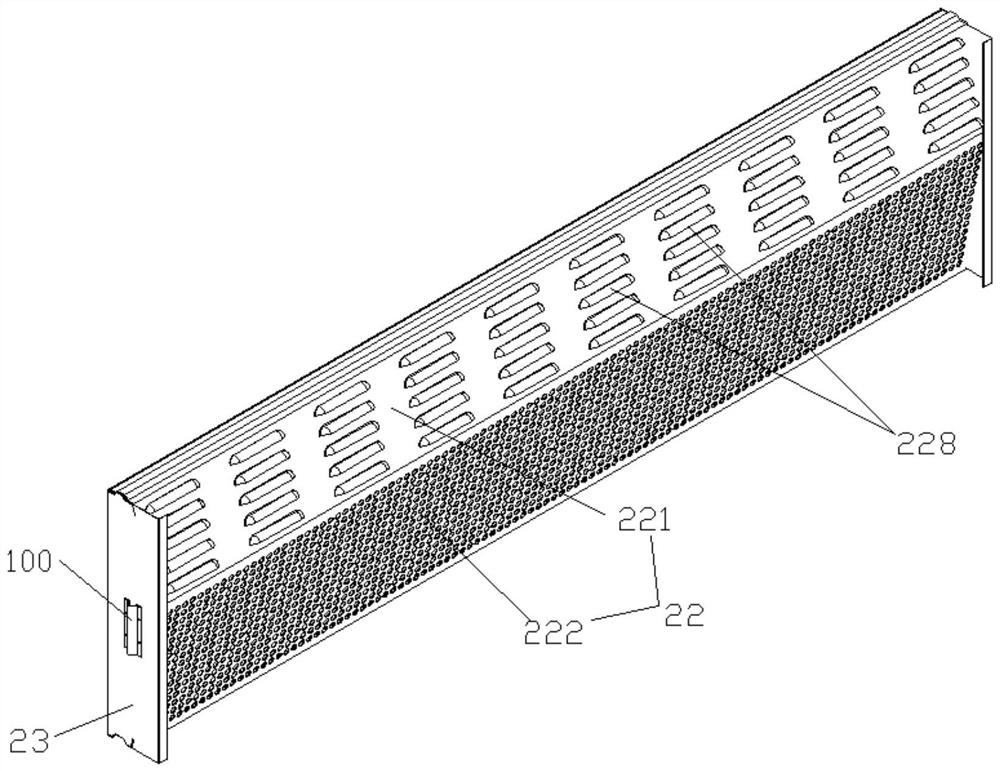

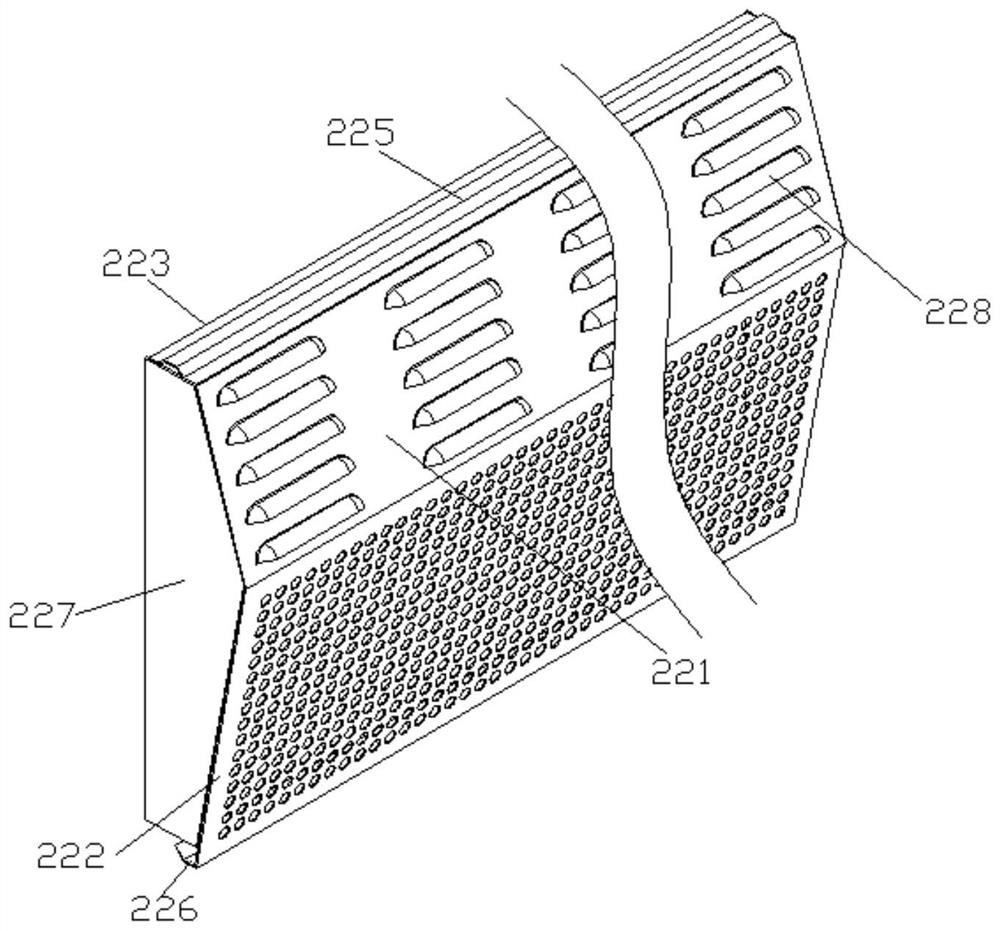

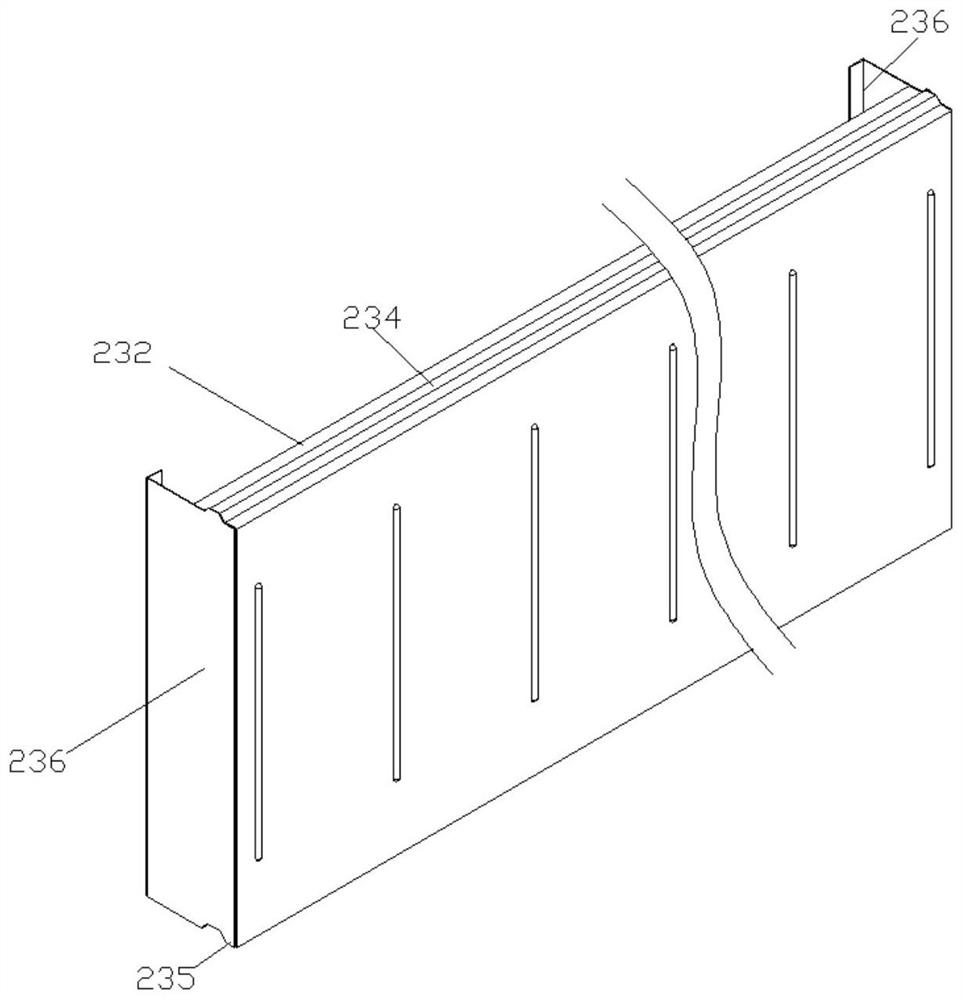

[0026] see in conjunction Figure 1 to Figure 6 As shown, according to an embodiment of the present invention, an upright metal sound barrier unit panel is provided, including a sound absorption module 21, and the side of the sound absorption module 21 facing the sound source is provided with a perforated panel 22, and the sound absorption module 21 is provided with a back plate 23 on the side away from the sound source, the perforated panel 22 and the back plate 23 are assembled and connected as a whole, and together form a package around the outer peripheral side of the sound-absorbing module 21, the perforated The panel 22 has a first perforated plate 221 and a second perforated plate 222. The first perforated plate 221 is located above the second perforated plate 222. From top to bottom along the height direction, the first perforated plate 221 gradually Away from the sound-absorbing module 21, the second perforated plate 222 gradually approaches the sound-absorbing module...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com