An intelligent casing scraper for ultra-deep wells

A technology of wall scraper and ultra-deep well, which is used in cleaning tools, wellbore/well components, earth-moving drilling, etc. It can solve the problems of low wall scraping efficiency, stuck drill, and easy resistance of wall scrapers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

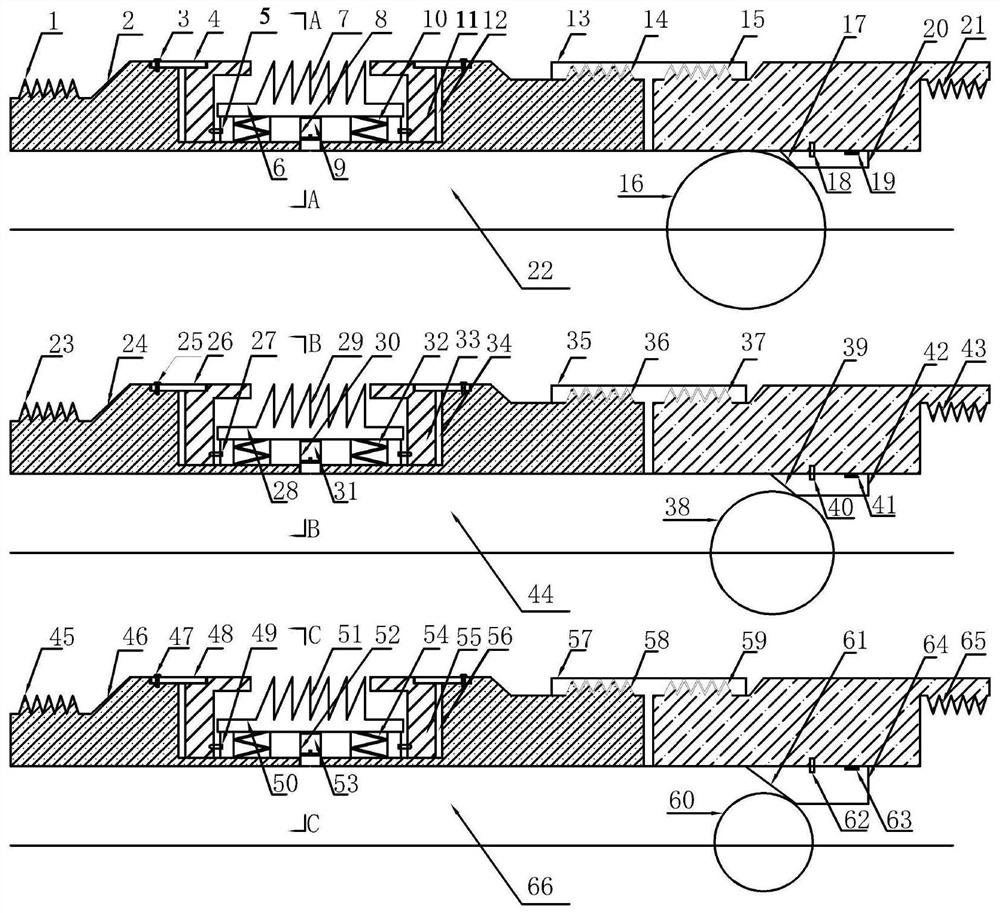

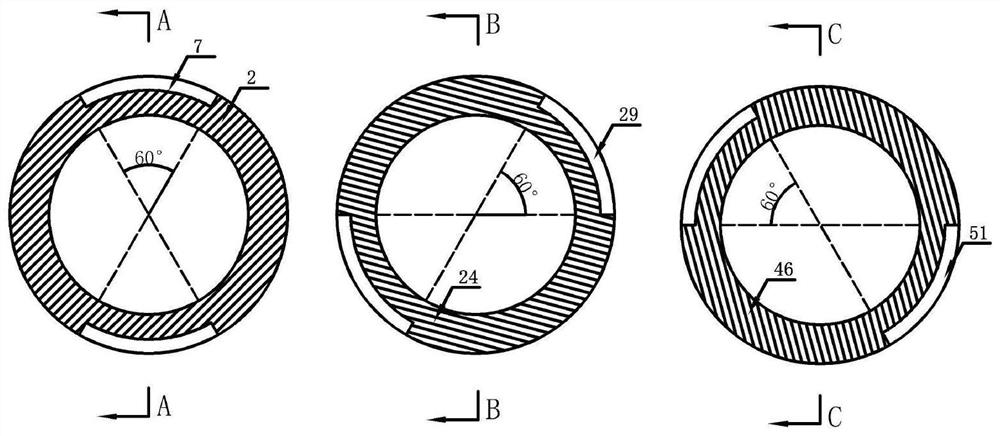

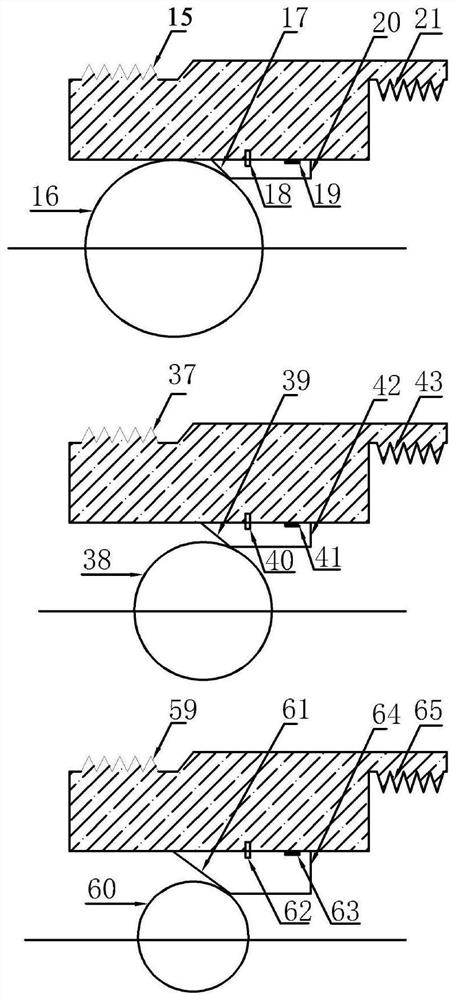

[0018] As shown in the accompanying drawings, an ultra-deep well casing intelligent wall scraper proposed by the present invention mainly includes: a first upper joint 1, a first body 2, a first locking bolt 3, a first positioning plate 4, a first Shear pin 5, first scraper group 6, first group of fish scale scraper blades 7, first pressure-bearing rubber seal sleeve 8, first pressure-bearing chamber 9, first spring 10, first pressure block 11, first Groove 12, first double female conversion joint 13, first male buckle 14, first sliding sleeve male buckle 15, first low-density steel ball 16, first ball seat 17, first shear pin 18, first gasket Sheet 19, first sliding sleeve 20, first sliding sleeve female buckle 21, first wall scraper 22, second upper joint 23, second body 24, second locking bolt 25, second positioning plate 26, second The shear pin 27, the second scraper group 28, the second group of fish-scale scraper blades 29, the second pressure-bearing rubber seal sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com