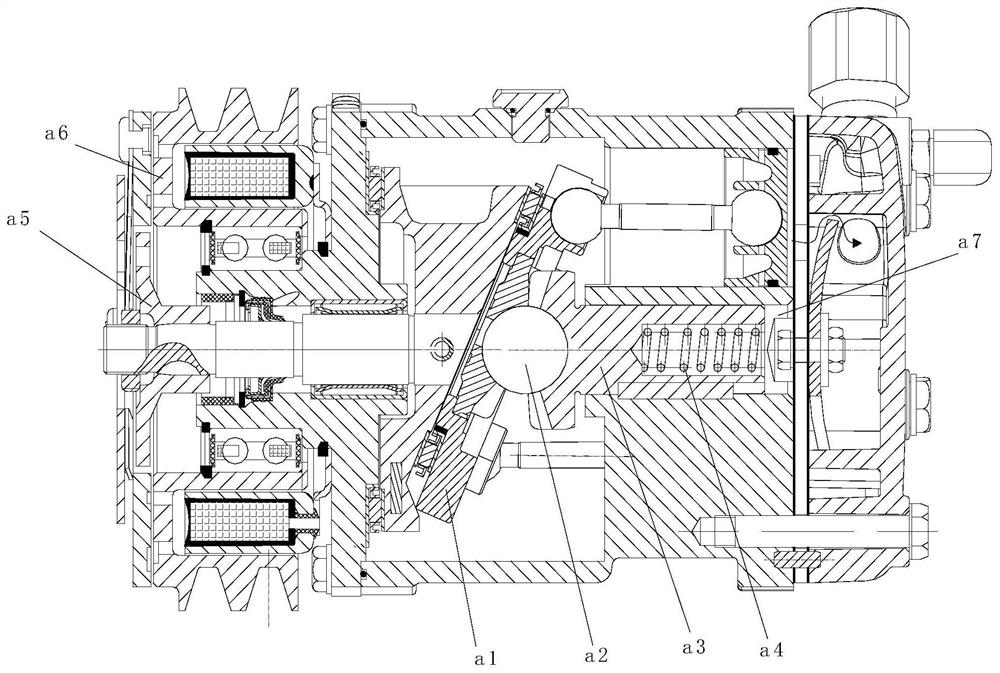

Vibration reduction compressor

A compressor and high-pressure technology, applied in the field of compressors, can solve problems such as affecting the compressor, producing mechanical noise, and easy failure of the spring a4

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

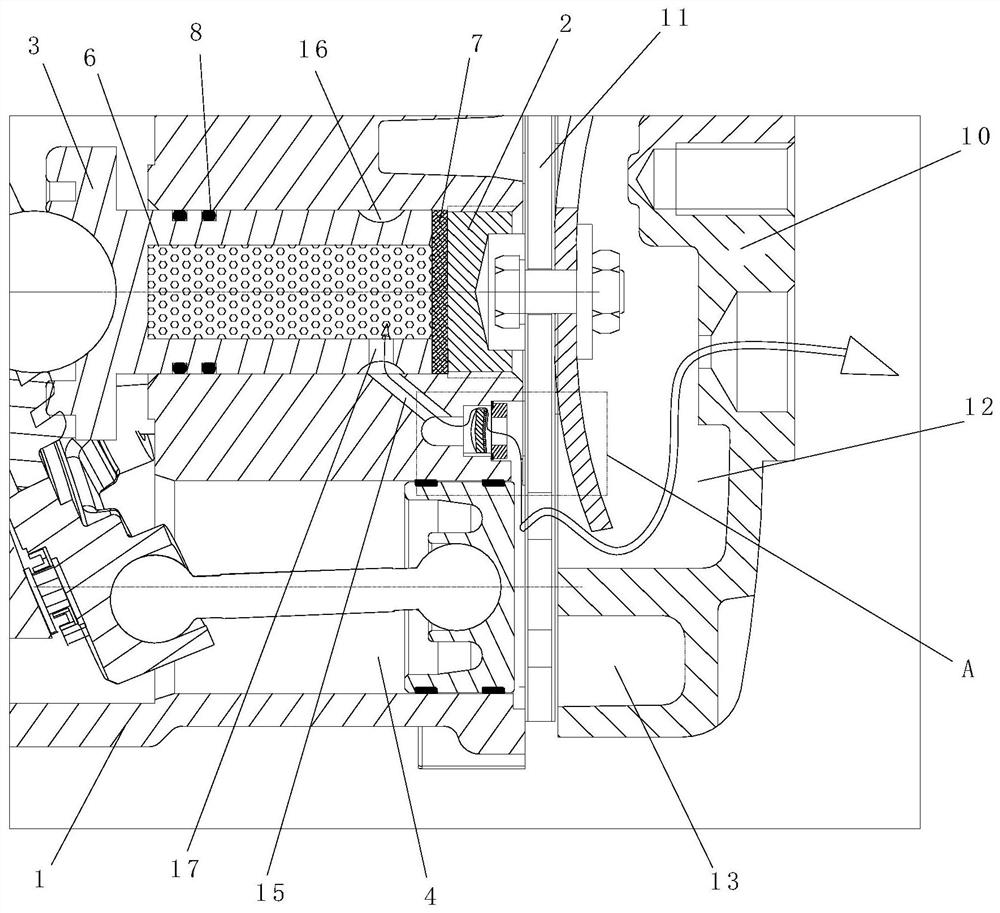

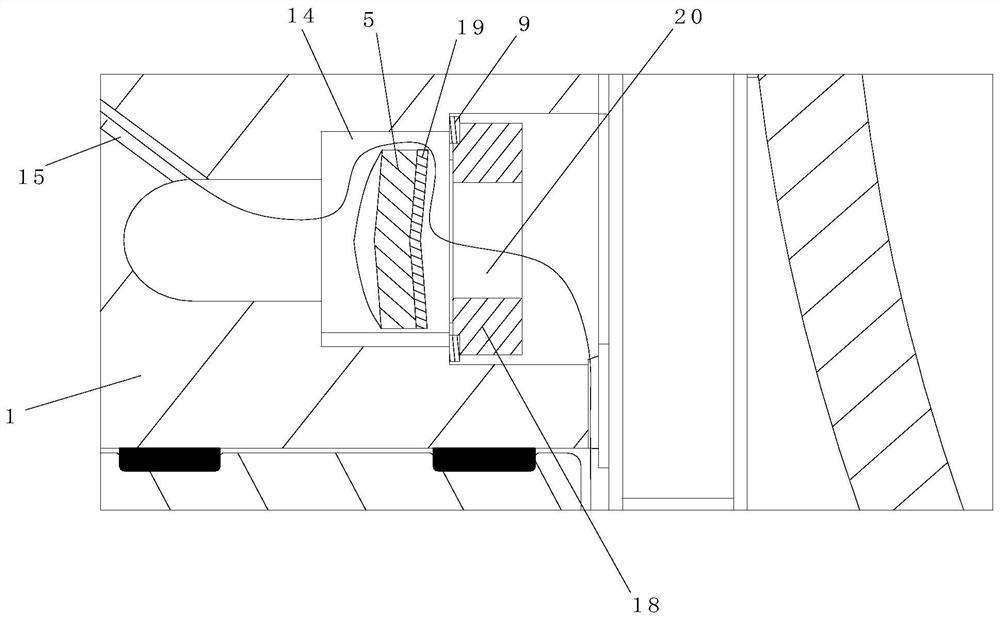

[0016] refer to figure 2 , image 3 , the present invention proposes a damping compressor, including a cylinder 1, an adjusting screw plug 2 and a positioning gear 3, wherein:

[0017] Both ends of the cylinder body 1 are respectively fixedly connected with an upper cylinder head and a lower cylinder head 10, a valve plate 11 is arranged between the cylinder body 1 and the lower cylinder head 10, and an exhaust chamber 12 is formed between the valve plate 11 and the lower cylinder head 10 and the suction chamber 13 , the cylinder block 1 is provided with a cylinder bore 4 communicating with the exhaust chamber 12 and the suction chamber 13 . One end of the positioning gear 3 close to the adjusting screw plug 2 is provided with a high-pressure damping chamber 6 extending from its end face to the inside, and the cylinder body 1 is provided with a communication cylinder hole 4 and a high-pressure damping chamber 6 to allow the gas in the cylinder bore 4 to enter the high-pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com