Power gear shifting transmission and control system thereof

A technology for power shifting and control systems, applied in the direction of transmission control, components with teeth, belts/chains/gears, etc., can solve problems such as difficult to meet requirements, high cost, and self-heavy, and achieve the starting shift process Smooth, automated results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

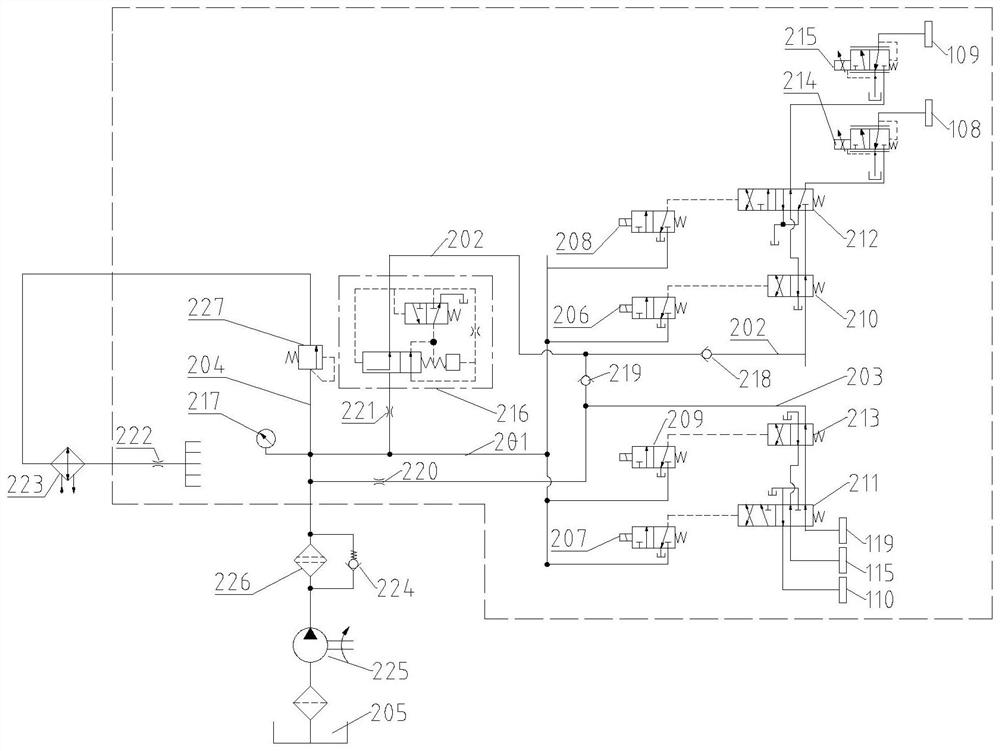

[0062]As a preferred embodiment, upstream of the second sub-oil path 202 and the third point of oil passage 203 respectively provided a first throttle valve 220, and a second throttle valve 221, respectively.

[0063]As a preferred embodiment, the output of the oil pump 225 is also provided with a safety valve 224.

[0064]As a preferred embodiment, the downstream of the fourth point of oil 204 is provided with a third throttle valve 222.

[0065]As a preferred embodiment, a cooler 223 is also provided between the main pressure valve 227 of the fourth point of oil 204 and the third throttle 222.

[0066]The above power shifting transmission is preferably used on a roller, based on this, the present embodiment also provides a roller having the power shifting transmission.

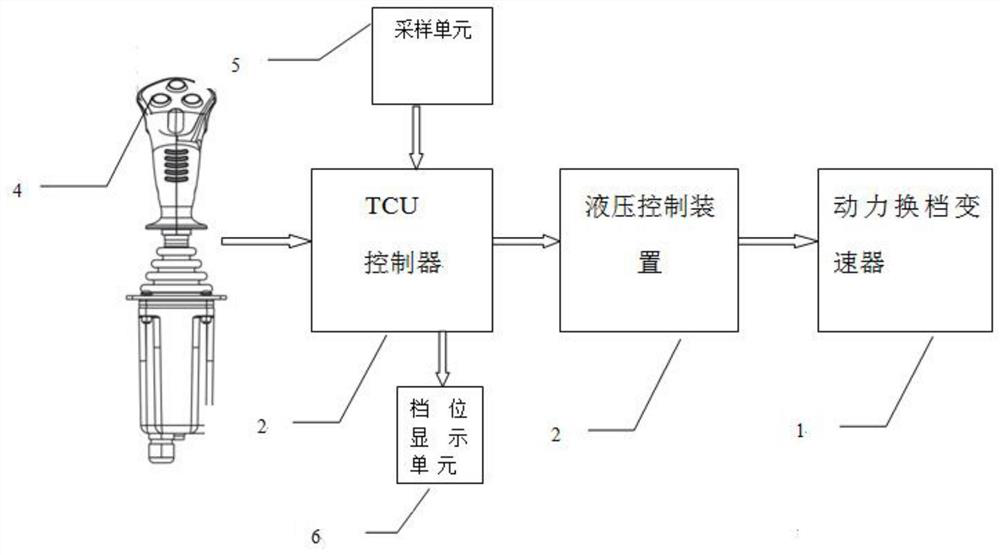

[0067]This embodiment also provides a control system for power shifting transmission 1, such asimage 3 As shown, the system includes: controller 3, operating handle 4, sampling unit 5, a gear display unit 6, and a hydraulic cont...

Example Embodiment

[0090]As a preferred embodiment, the first oil pressure P1 ∈ [1 / 4p, 2 / 5p]. When the full pressure is 20bAr, P1 is preferably 6 bar.

[0091]As a preferred embodiment, such asFigure 5 As shown, when the start-shifting demand is flat or flat, the control roller is increased to the control roller to the full pressure, which is 2-3S, which is a gentle boost process, thereby starting or shifting the process. More smooth.

[0092]As a preferred embodiment, such asFigure 6 As shown, when the start-demand is a ramp, the control oil pressure is increased to the full hydraulic pressure, and specifically includes eliminating the gap boosting stage and the fast-binding boost stage, wherein eliminating the gap boosting phase consumption When T2 is 40-100ms, the fast boosting phase consumption T3 is 60-100ms, which is more fast than the flat start process, and the purpose is to quickly combine the corresponding direction clutch tray, the purpose is to make the corresponding The direction of the clutc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com