Boiler slag well and hydraulic crushing shutoff door expansion joint connecting system

A hydraulic crushing and connection system technology, applied in the field of boiler slag removal system, can solve the problems of small expansion, high installation space, easy damage, etc., and achieve the effect of compensating for size changes and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

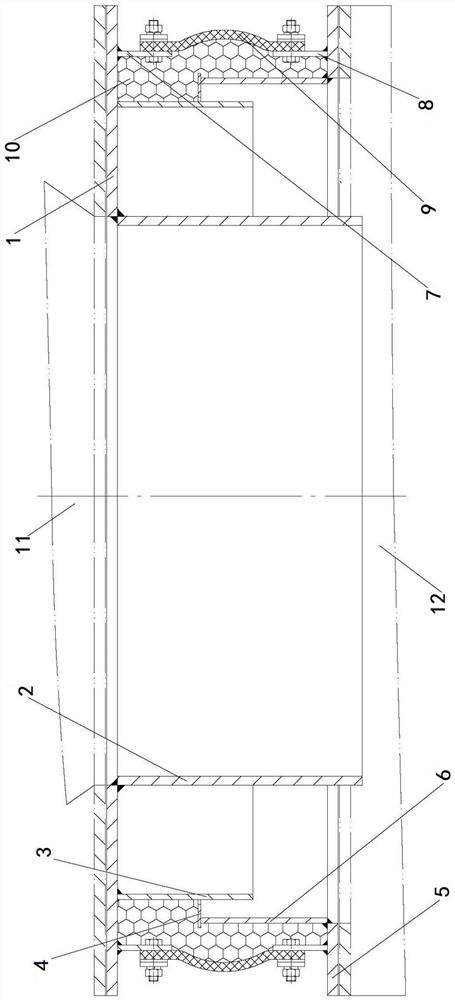

[0016] exist figure 1 Among them, the expansion joint connection system between the boiler slag well and the hydraulic crushing shut-off door of the present invention includes an annular upper plate 1 installed on the bottom surface of the upper slag well 11 and having a slag discharge port, and an inner pipe body 2 installed on the annular upper plate , the first regulating pipe body 3 located on the outside of the inner pipe body and installed on the annular upper plate, the annular sealing plate 4 sleeved on the first regulating pipe body, the annular sealing plate is lifted up and installed on the lower hydraulic breaking shut-off door 12 The lower plate 5 on the top surface, the second adjusting pipe body 6 located outside the first regulating pipe body and installed on the lower plate, the upper baffle plate 7 installed on the annular upper plate, the lower baffle plate 8 installed on the lower plate, The curved non-metallic temperature-resistant and pressure-bearing sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com