Anti-scalding oil heater

An anti-scalding oil scalding and oil scalding technology, which is applied in the directions of household heating, space heating and ventilation details, heating methods, etc., can solve the problems of cumbersome manufacturing process, affecting appearance consistency, increasing material cost, etc., and achieves convenient operation. Fast, good anti-scalding effect, the effect of saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

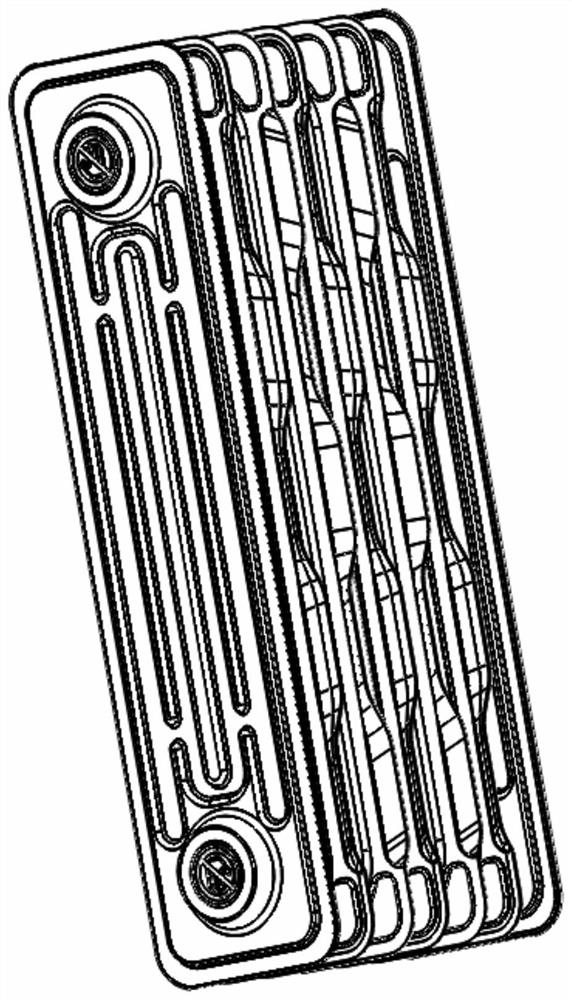

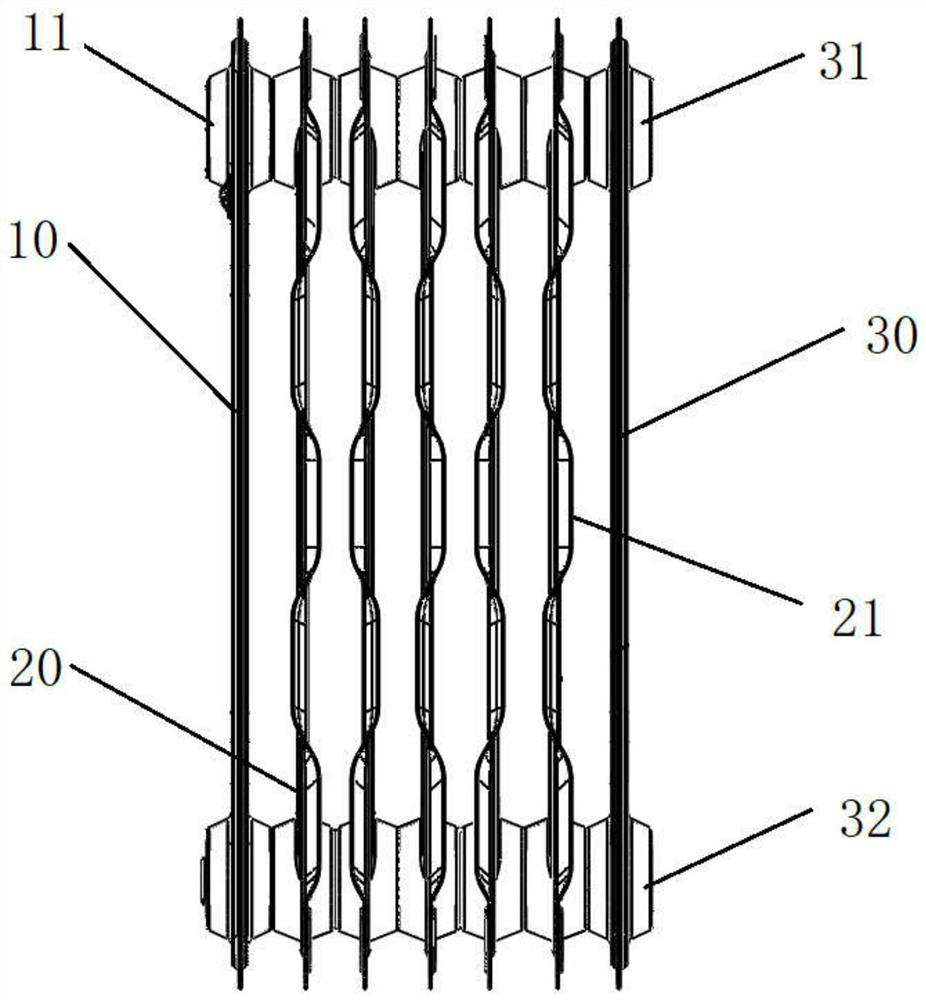

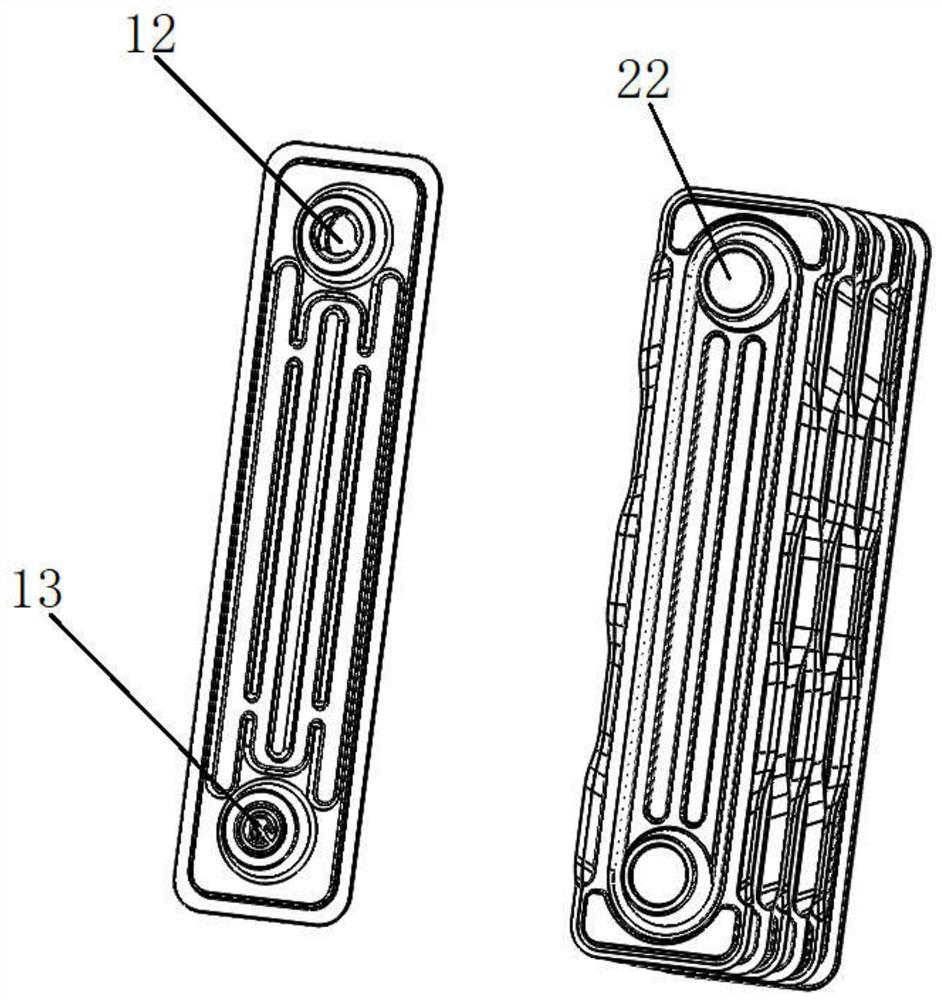

[0032] In the last heat dissipation unit 20 of this embodiment, only the second heat sink 24 is provided with oil guide holes, and the first heat sink 23 is not provided with oil guide holes. The final cooling unit 10 is also composed of two cooling fins, including a first cooling fin 15 and a second cooling fin 16 . Such as Figure 3-6 As shown, in one embodiment, the first heat dissipation fin 15 of the last heat dissipation unit 10 is provided with openings 12, and the second heat dissipation fin 16 of the last heat dissipation unit 10 is not provided with openings, so that the last heat dissipation unit 20 and the last heat dissipation unit An isolated connection is formed between the heat dissipation units 10, that is, there is no channel for the circulation of heating oil between the last heat dissipation unit 20 and the last heat dissipation unit 10, but the oil hole of the last heat dissipation unit 20 is isolated from the last heat dissipation unit 10 . Such as Fi...

Embodiment 2

[0035] In the last heat dissipation unit 20 of this embodiment, only the second heat sink 24 is provided with oil guide holes, and the first heat sink 23 is not provided with oil guide holes. The final cooling unit 10 is also composed of two cooling fins, including a first cooling fin 15 and a second cooling fin 16 . Such as Figure 8 As shown, the first heat sink 15 and the second heat sink 16 of the last heat dissipation unit are not provided with openings. At this time, because there is no opening, the welding equipment cannot extend into the inside of the end cooling unit for spot welding. In this embodiment, the second heat dissipation fin 16 of the last heat dissipation unit and the first heat dissipation fin 23 of the last heat dissipation unit can be welded from the outside, as Figure 8 As shown, the welding portion 40 between the last heat dissipation unit and the second last heat dissipation unit is shown.

Embodiment 3

[0037] In the last heat dissipation unit 20 of this embodiment, only the second heat sink 24 is provided with oil guide holes, and the first heat sink 23 is not provided with oil guide holes. The final cooling unit 10 is also composed of two cooling fins, including a first cooling fin 15 and a second cooling fin 16 . Such as Figure 9 As shown, the first heat sink 15 and the second heat sink 16 of the last heat dissipation unit are not provided with openings. During processing, first the second heat sink 16 of the last heat dissipation unit is spot-welded with the first heat sink 23 of the last heat dissipation unit, and then the first heat sink 15 and the second heat sink 16 of the last heat dissipation unit are welded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com