Patient heat preservation cup with reminding function

A thermos cup and patient technology, which is applied to drinking utensils and other directions, can solve problems such as scalding of thermos cups, achieve good thermal insulation effect, avoid insufficient drinking water, and avoid dehydration problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

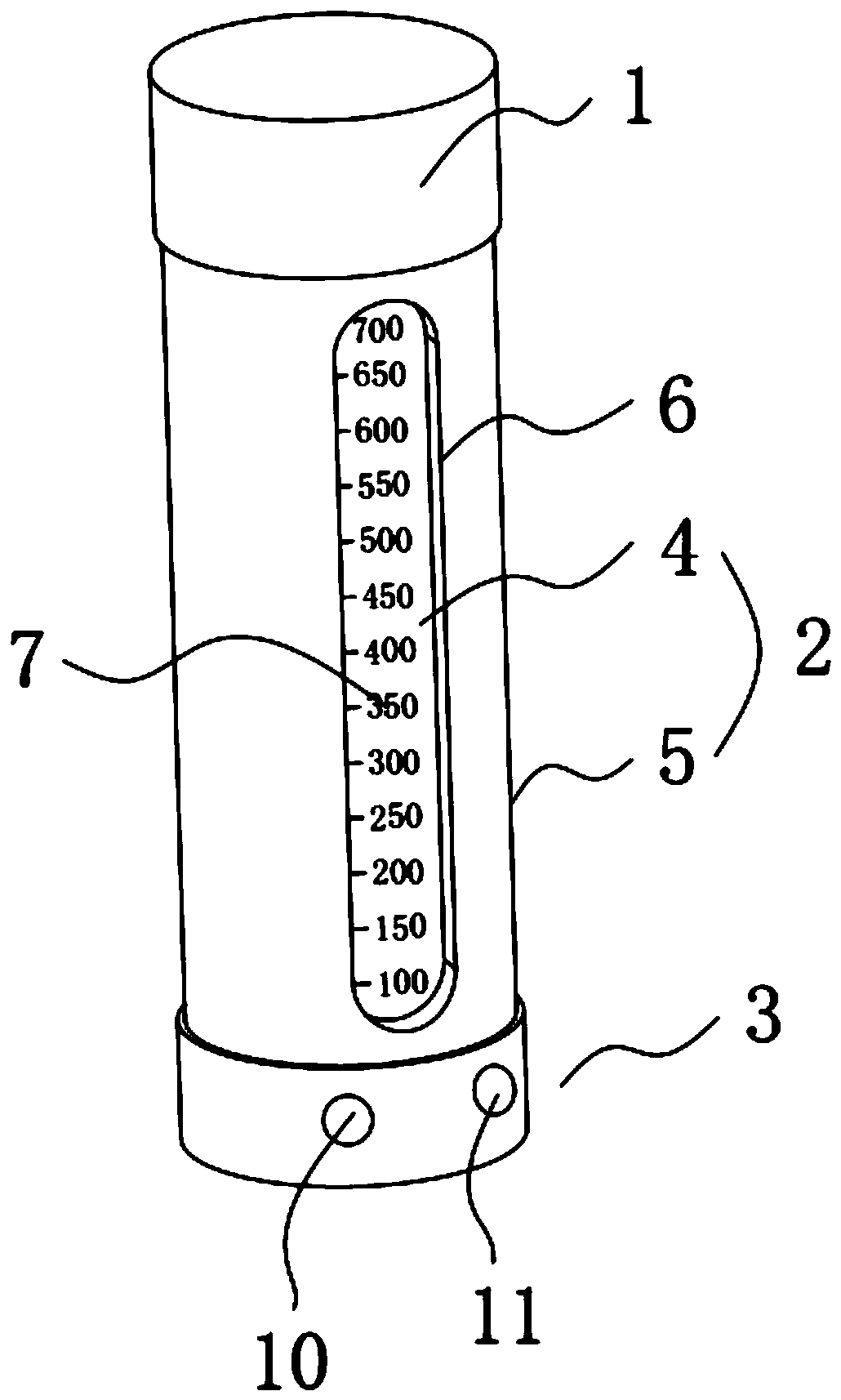

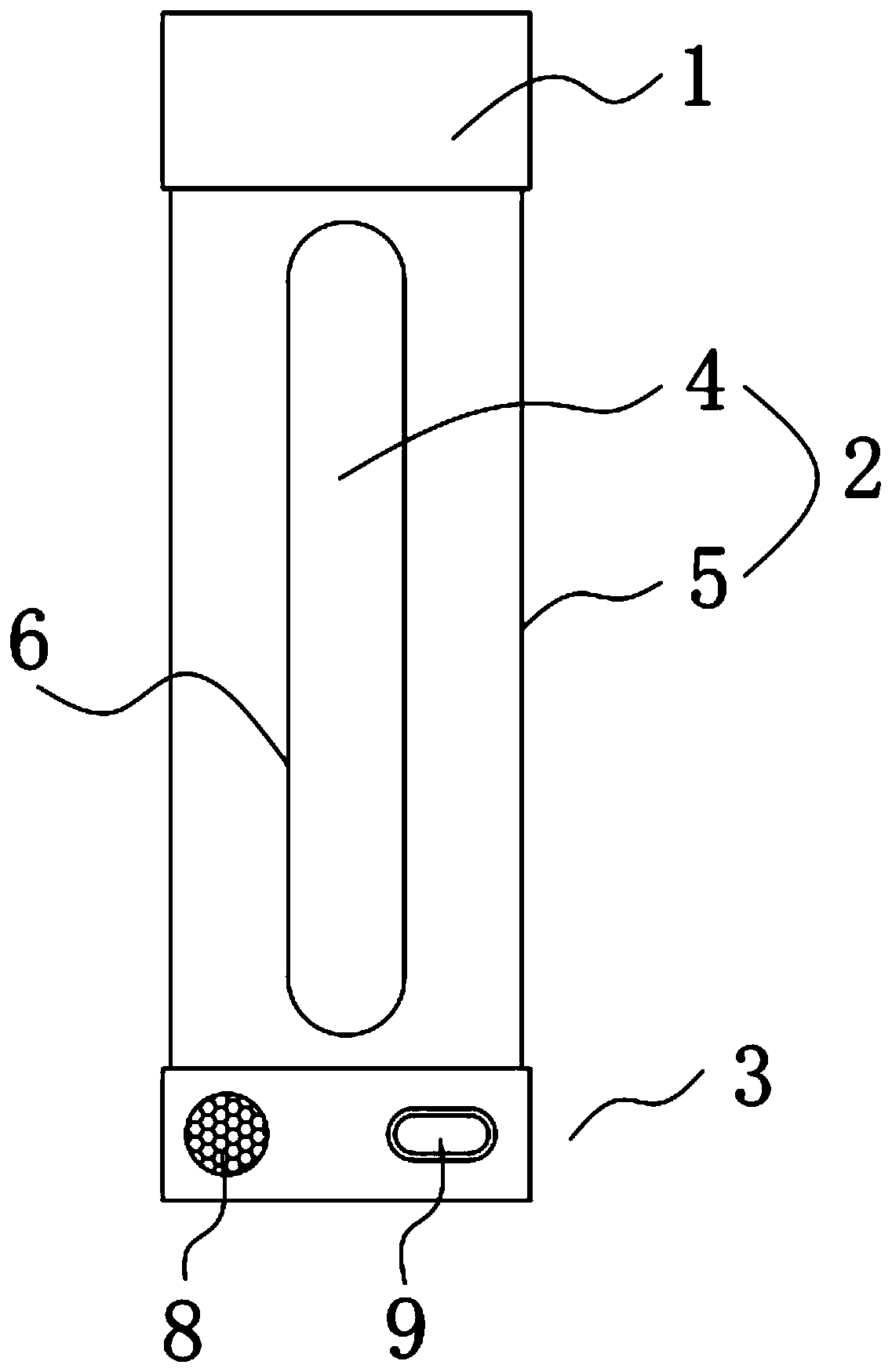

[0044] The following is attached Figure 1-5 The present invention is described in further detail.

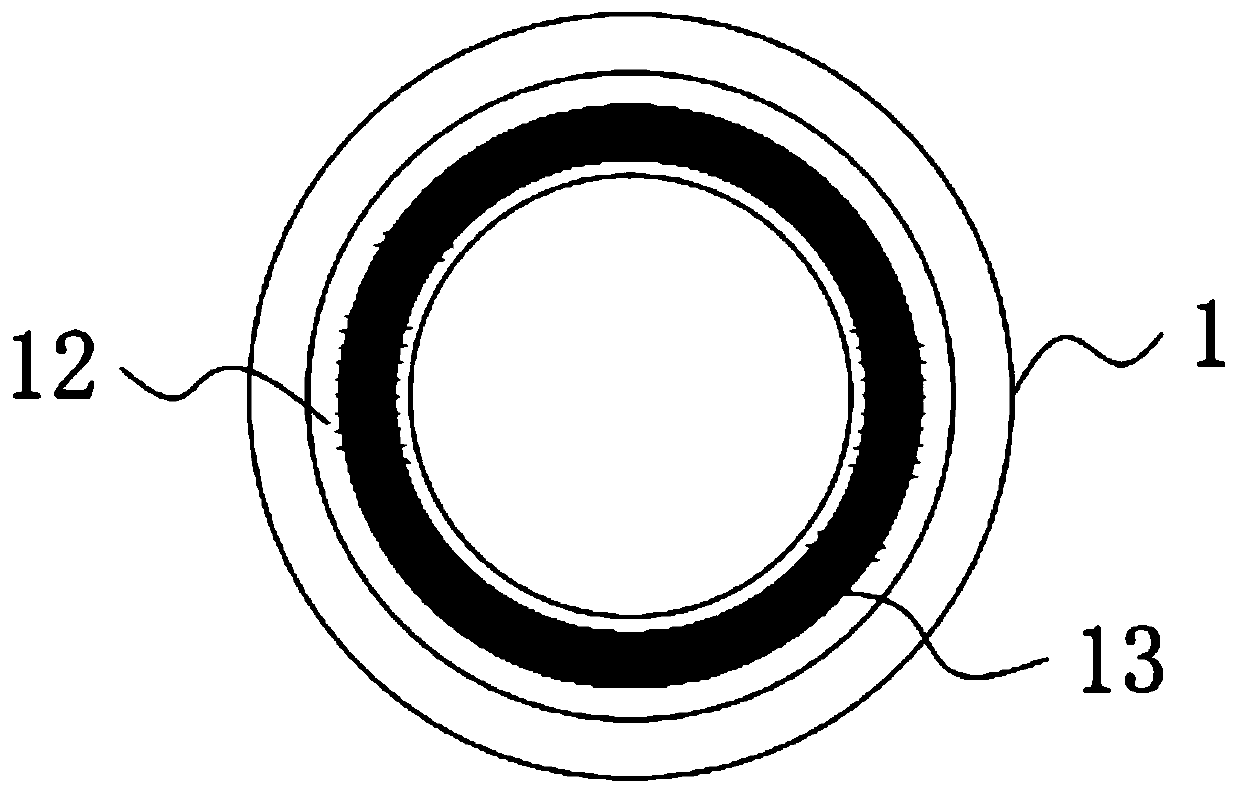

[0045] A patient thermos cup with reminder function, such as Figure 1-5 As shown, it includes a cup cover 1, a cup body 2 and an induction cup bottom 3, the cup cover 1 is arranged on the upper end of the cup body 2, and the cup body 2 is fixedly installed on the upper part of the induction cup bottom 3;

[0046] The induction cup bottom 3 includes a cylindrical housing 14, a partition 18 is installed in the center of the cylindrical housing 14, and an arc-shaped groove 15 is opened on the upper surface of the partition 18, and the arc-shaped concave The edge of the groove 15 is inlaid with a ring-shaped induction coil 17, and the interior of the arc groove 15 is provided with a freely movable induction ball 16, and the inner bottom of the cylindrical shell 14 is located below the partition 18 and a battery 19 is fixedly installed and a DSP controller 20, a first indicator l...

Embodiment 2

[0064] The difference from Example 1 lies in the preparation of the anti-scalding cylindrical shell, and its specific preparation method is as follows:

[0065] Take the following raw materials and weigh them by weight: 70 parts of polyethylene, 35 parts of polypropylene, 50 parts of melamine resin, 5 parts of expanded vitrified microbeads, 11 parts of perlite powder, 8 parts of mica powder, 7 parts of plant collagen, 3 parts of anti-aging agent, 4 parts of accelerator;

[0066] S1. Put the weighed polyethylene, polypropylene, melamine resin, expanded vitrified microspheres, perlite powder, and mica powder into the dryer for drying. The temperature of the dryer is set to 70°C, and the speed is set to 750r / min, the drying time is 18min, and the dry material is obtained;

[0067] S2. Add the dry material, plant collagen, anti-aging agent and accelerator prepared in step S1 into a mixer for stirring and mixing. The temperature of the mixer is set to 90°C, the speed is set to 70...

Embodiment 3

[0072] The difference from Example 1 lies in the preparation of the anti-scalding cylindrical shell, and its specific preparation method is as follows:

[0073] Take the following raw materials and weigh them by weight: 80 parts of polyethylene, 40 parts of polypropylene, 60 parts of melamine resin, 6 parts of expanded vitrified microbeads, 12 parts of perlite powder, 9 parts of mica powder, 8 parts of plant collagen, 4 parts of anti-aging agent, 5 parts of accelerator;

[0074] S1. Put the weighed polyethylene, polypropylene, melamine resin, expanded vitrified microspheres, perlite powder, and mica powder into the dryer for drying. The temperature of the dryer is set to 80°C, and the speed is set to 800r / min, the drying time is 20min, and the dry material is obtained;

[0075] S2. Add the dry material, plant collagen, anti-aging agent and accelerator prepared in step S1 into the mixer for stirring and mixing. The temperature of the mixer is set to 100°C, the speed is set to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com