Dragging type disassembly-free gas leakage detection device for gas transmission pipeline

A detection device and gas pipeline technology, which is used in measurement devices, pipeline systems, and liquid/vacuum measurement for liquid tightness. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

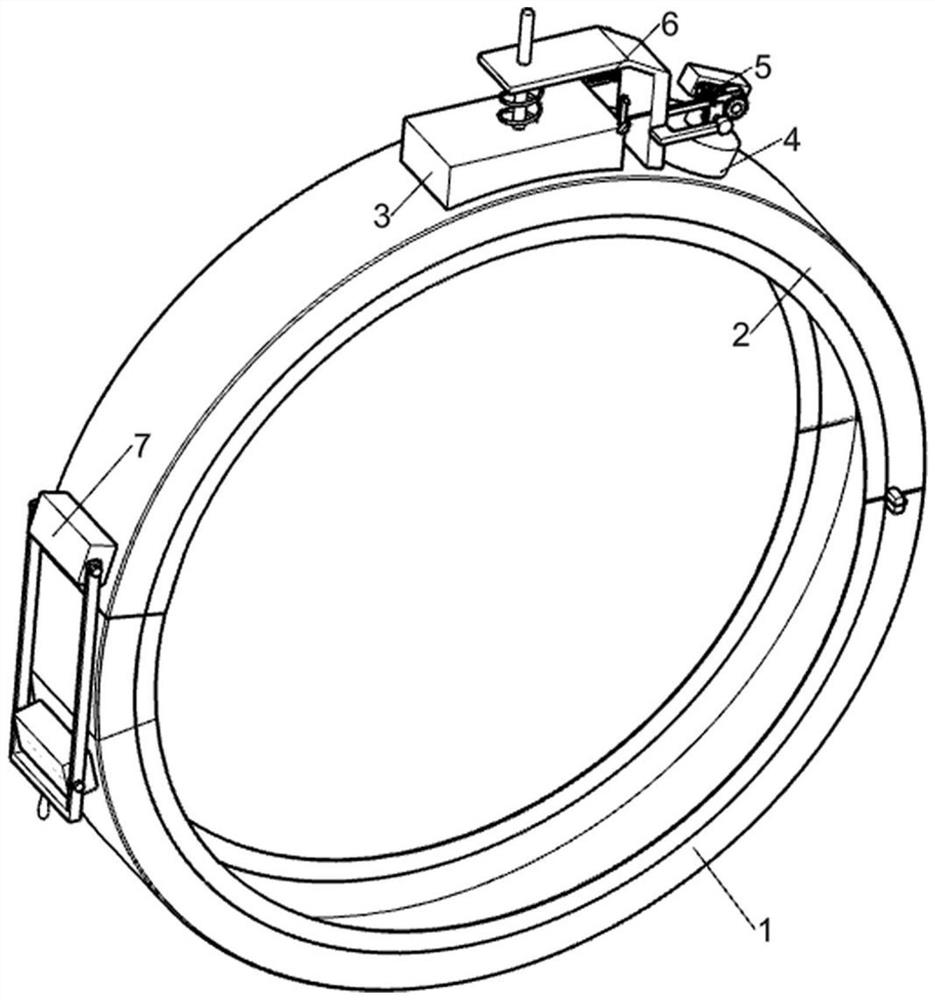

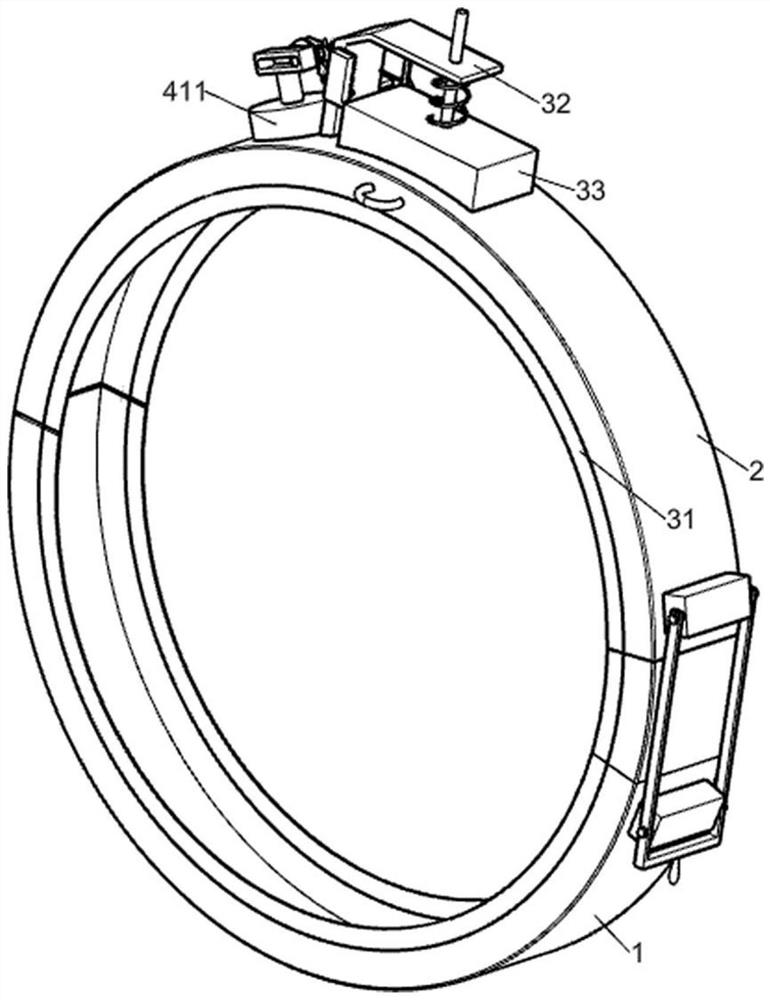

[0028] A drag-type non-dismantling gas leakage detection device for gas pipelines, such as Figure 1-10 As shown, it includes a first clamping ring 1, a second clamping ring 2, a pressure measuring assembly 3 and a pressure reducing assembly 4, the first clamping ring 1 is connected with the second clamping ring 2 through a hinge, the first The clamping ring 1 and the second clamping ring 2 are used to clamp the gas pipeline, the pressure measuring component 3 used to detect whether the gas pipeline leaks is set on the second clamping ring 2, and the pressure reducing component 4 is set on the On the pressure measuring component 3.

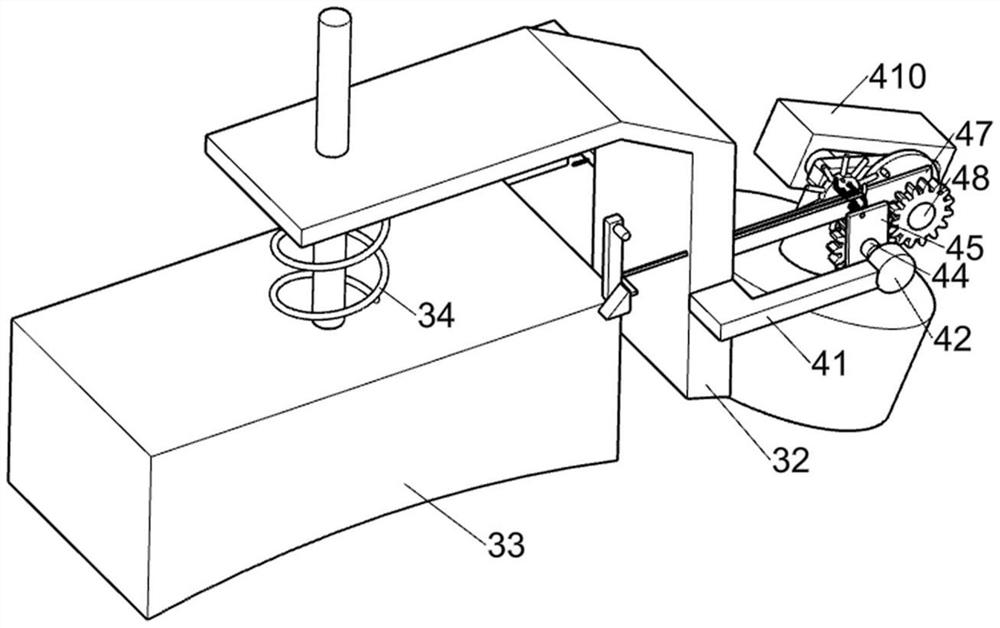

[0029] The pressure measuring assembly 3 includes an airtight ring 31, a first support frame 32, a sliding frame 33 and a first spring 34. The airtight ring 31 is symmetrically fixed on the first clamping ring 1. The airtight ring 31 is used for feeding the gas pipeline and The airtight conditions are created between the devices, the second clamp...

Embodiment 2

[0033] On the basis of Example 1, such as Figure 5-8 As shown, the air extraction auxiliary assembly 5 is included, and the air extraction auxiliary assembly 5 is arranged on the decompression assembly 4. The air extraction auxiliary assembly 5 includes a turntable 51 with clamping column, a dial 52, a sliding resistance frame 53, a second spring 54. Blocking ring 55, first torsion spring 56, fixed post 57, first sliding wedge frame 58, first support block 59, third spring 510, second sliding wedge frame 511, fourth spring 512, push rod 513 , connecting rod 514, wedge-shaped block 515 and clamp frame 516, band clamp rotating disk 51 is affixed on the band clamp rotating frame 48, band clamp rotating disc 51 is used to push dial 52, away from U-shaped support plate 45 A dial 52 is fixedly connected to the hexagonal rotating shaft 413, one end of the return spring 414 is fixedly connected to the dial 52, and a sliding resistance frame 53 is slidably connected to the second supp...

Embodiment 3

[0036] On the basis of Example 2, such as Figure 8-9 As shown, a reminder assembly 6 is included, and the reminder assembly 6 is arranged on the pressure measurement assembly 3. The reminder assembly 6 includes a second support block 61, a raised strip plate 62, a swing plate 63, a second torsion spring 64 and a prompter 65, The first supporting frame 32 is fixedly connected with a second supporting block 61, one side of the sliding frame 33 is fixedly connected with a raised strip plate 62, and the second supporting block 61 is rotatably connected with a swinging plate 63, which is used to trigger the prompter 65, the swing plate 63 is in contact with the protruding bar plate 62, the second torsion spring 64 is connected between the swing plate 63 and the second support block 61, and a prompter 65 is affixed to the second support block 61 close to the swing plate 63, Prompter 65 is used for sending prompting sound, prompts the detection personnel here air pipeline leakage. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com