Intelligent fault diagnosis method of aero-engine control system sensor based on mode gradient spectral entropy

An aero-engine and control system technology, applied in the direction of engine testing, general control systems, control/regulation systems, etc., can solve problems such as unsatisfactory results, lack of basis, and poor performance of training models, so as to improve the fault detection rate and reduce Calculation time, easy hardware online implementation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

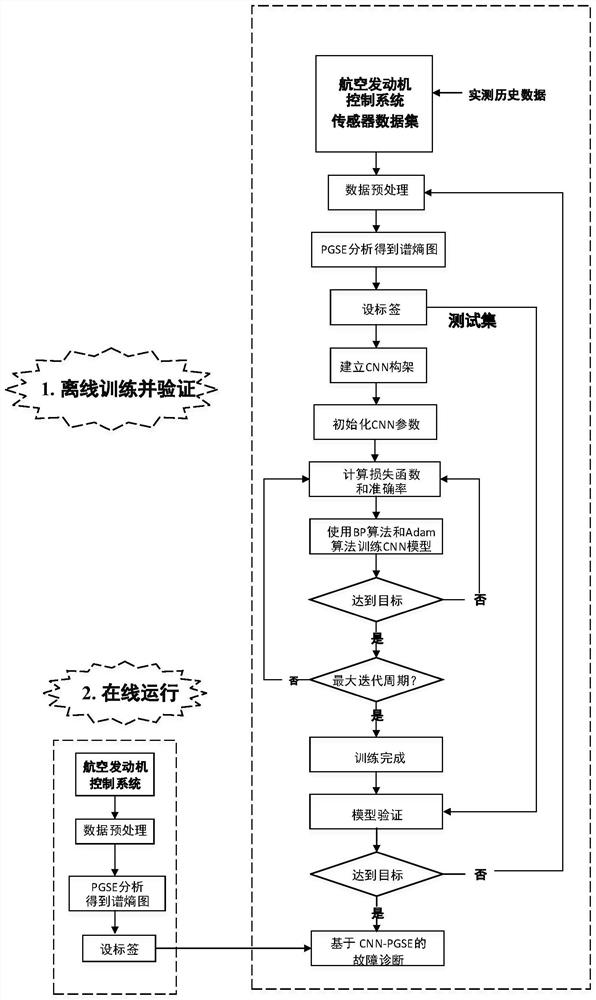

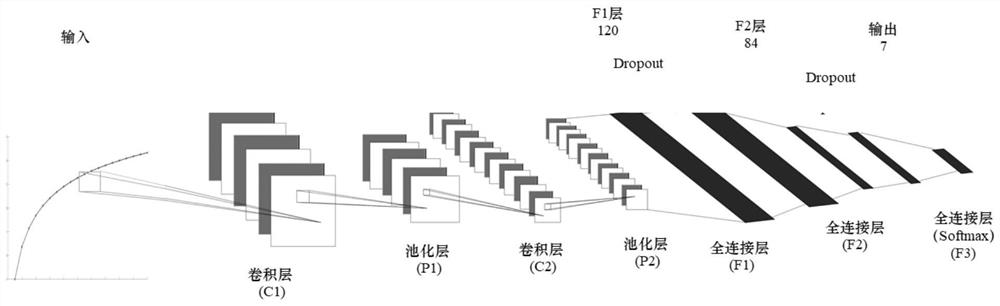

[0060] In order to accurately identify the fault mode of complex and nonlinear aeroengine control system sensors, the present invention is not sensitive to noise interference, and can accurately classify multiple fault modes, a method based on mode gradient spectral entropy and convolutional neural network is proposed. A fault diagnosis method for sensors in aero-engine control systems.

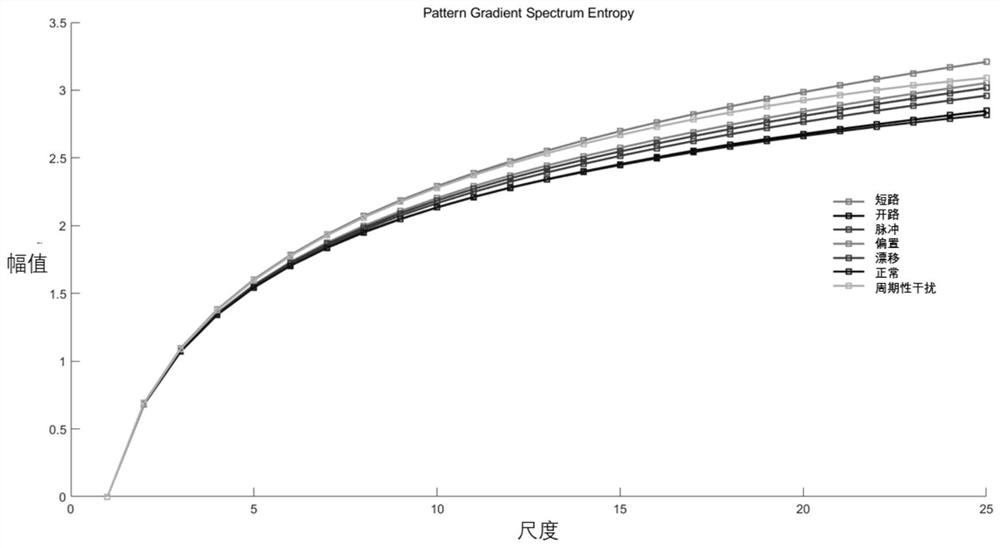

[0061] In this embodiment, the sensor faults of the aeroengine control system are classified according to the cause of the fault in advance, such as Figure 5 Shown:

[0062] (a) In normal condition, there is no cause of failure, and the serial number is 0;

[0063] (b) Bias fault, the cause of the fault is bias current or bias voltage, etc., numbered 1;

[0064] (c) Spike...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com