Glass insulator arrangement device and detection method

A technology of glass insulators and arrangement devices, applied in the directions of measuring devices, measuring device casings, measuring electricity, etc., can solve the problems of different lengths of inner conductors, high labor intensity, excessive use of eyes by staff, etc., and achieve easy-to-use insulator inner conductors. The effect of length, improving work efficiency and reducing vision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] The arrangement device of the present invention comprises a test board, a test board funnel, a microscope inspection board, a test frame and a conductive strip.

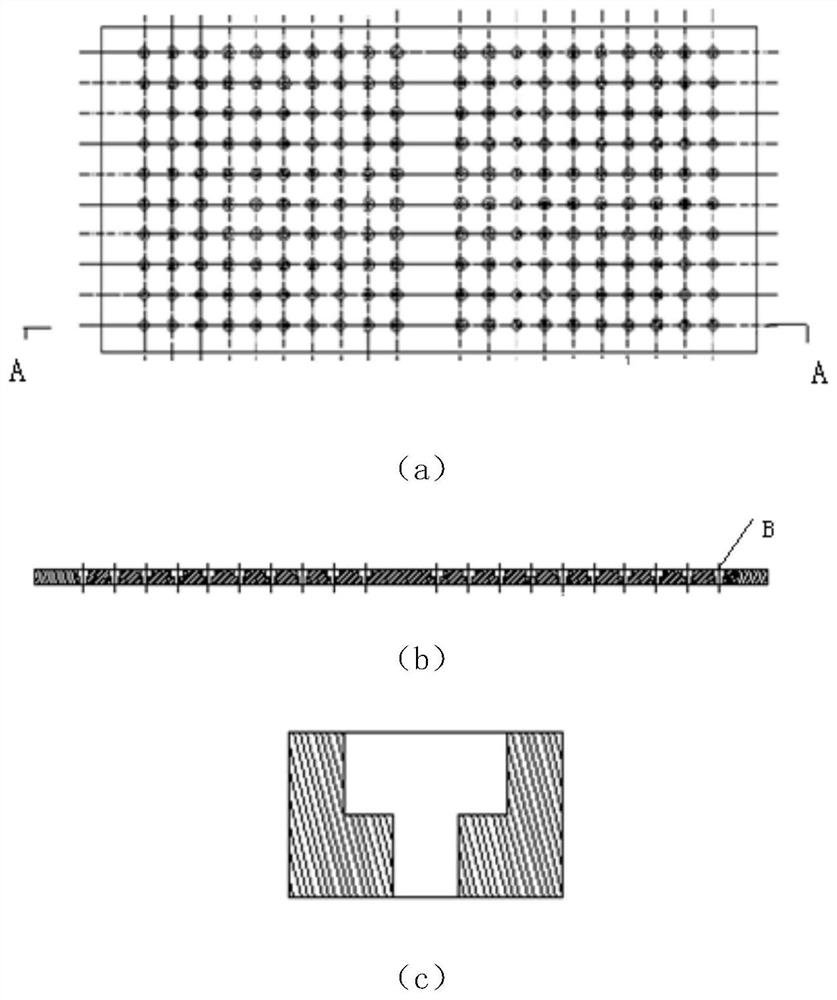

[0030] The structure of the test board is punched on the front, and the hole type is a stepped hole, such as figure 1 As shown, choose polytetrafluoroethylene or epoxy resin material. The diameter of the hole on the test insulator board is determined by the diameter of the outer conductor and inner conductor of the insulator.

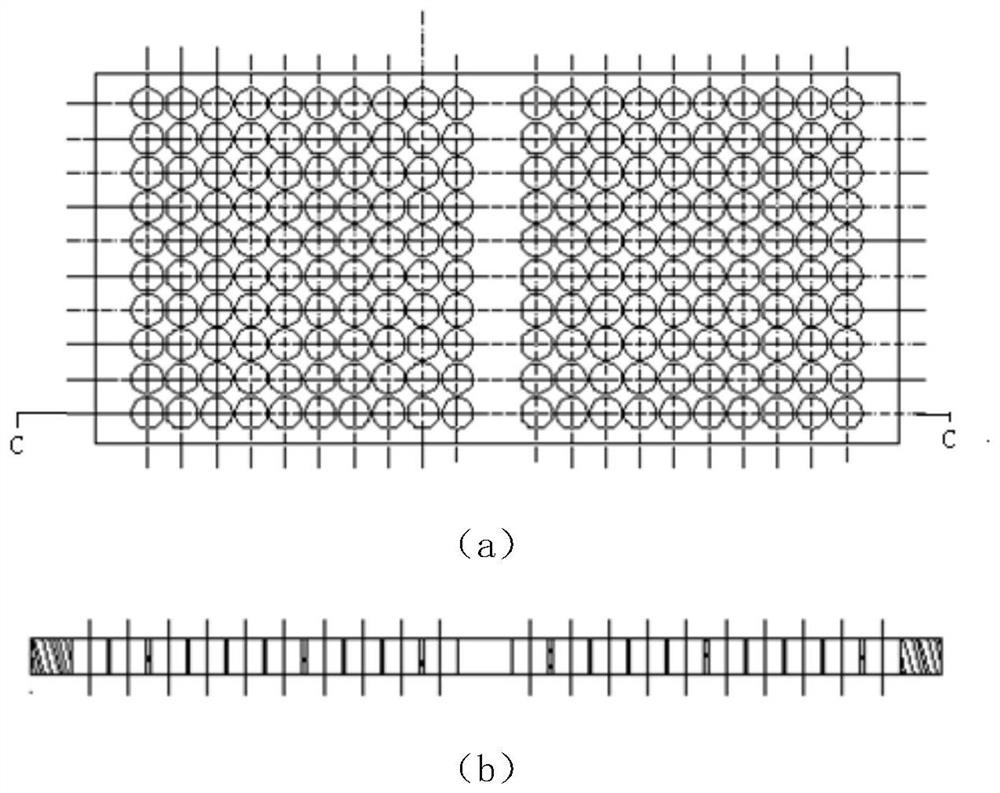

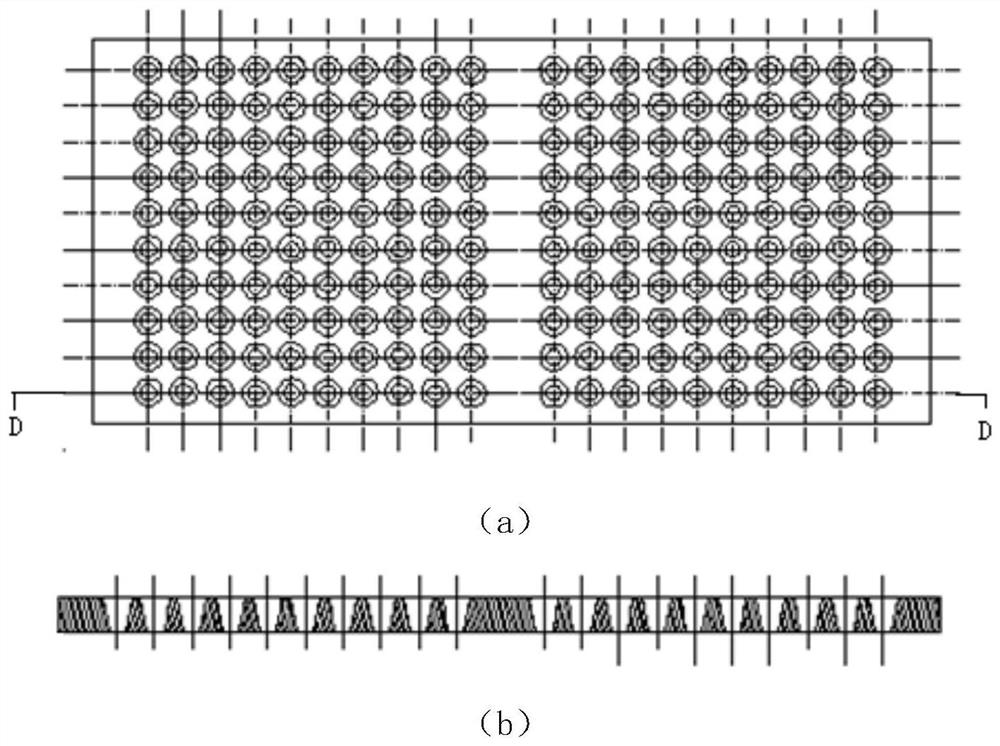

[0031] The structure of the test board funnel is divided into through-hole shape test board funnels (such as figure 2 shown) and the funnel of the eight-shaped test plate (such as image 3 shown). The aluminum material is used. After the funnel of the test board is processed, the electroplating is blackened to ensure no reflection.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com