Novel composite material and swing type friction nanometer generator using same

A nanogenerator and composite material technology, which is applied in triboelectric generators, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of thermal effect, single selection, and reduce the operation time of the device, and achieve high power output capability. , the effect of high charge output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

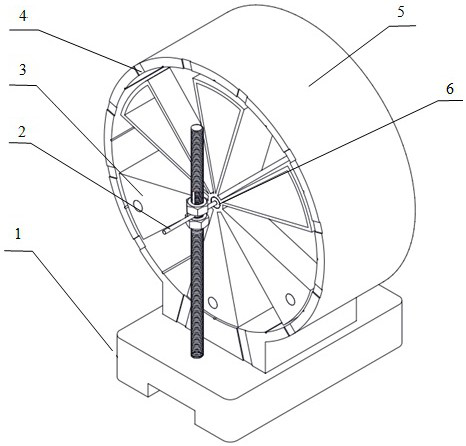

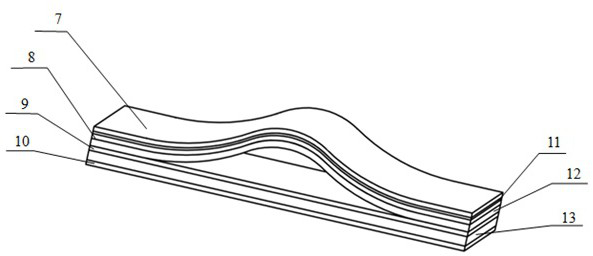

[0034] A new type of composite material is a layered structure, such as figure 2 As shown, from top to bottom are the first electrode layer 7, insulating layer 11, second electrode layer 8, PTFE friction layer 12, third electrode layer 9, BaTiO 3 The piezoelectric composite layer 13 and the fourth electrode layer 10, wherein the first electrode layer 7, the insulating layer 11, the second electrode layer 8, and the PTFE friction layer 12 are arched structures, and the presence of the arched structures makes the composite material subjected to horizontal When an external force is applied in the vertical direction, a friction effect is generated; when an external force is applied in a vertical direction, a piezoelectric effect is generated.

[0035] The preparation process of the novel composite material is as follows:

[0036] S1.1 Mix 85wt% barium titanate particles into the same quality HTV silica gel matrix to prepare BaTiO 3 Piezoelectric composites, the BaTiO 3 Piezoel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com