A multi-channel exhaust sparkling water machine

A sparkling water machine and gas bottle technology, which is applied to kitchen utensils, home utensils, beverage preparation devices, etc., can solve the problems of gas waste, unreasonable design of exhaust and pressure relief channels, and inability to discharge high pressure in the bottle in time. Convenience, reduced exhaust speed, good operating feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

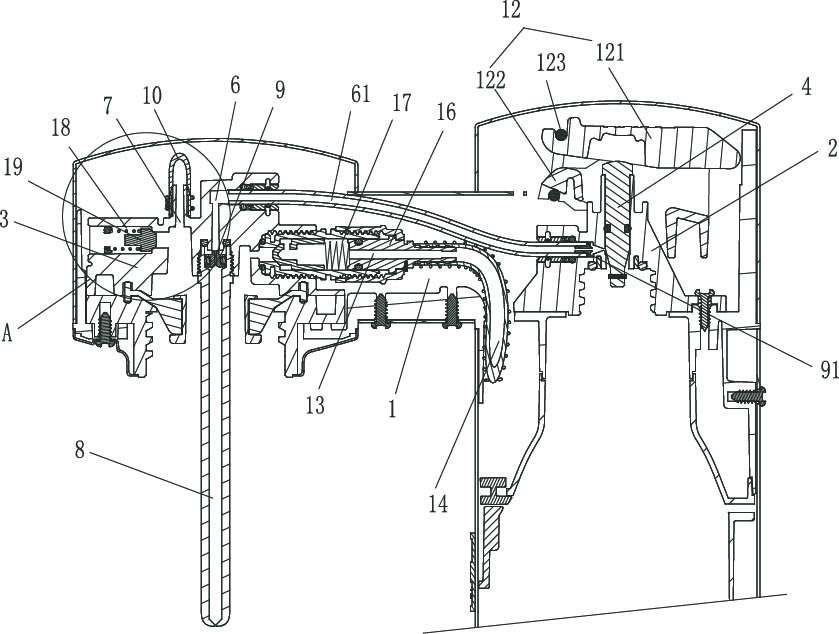

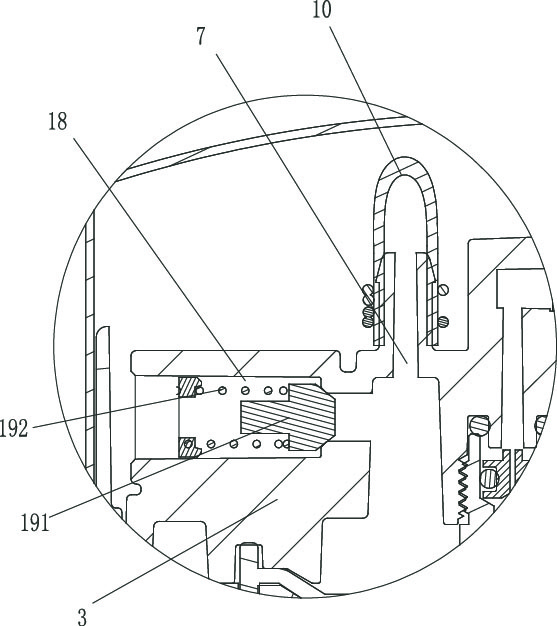

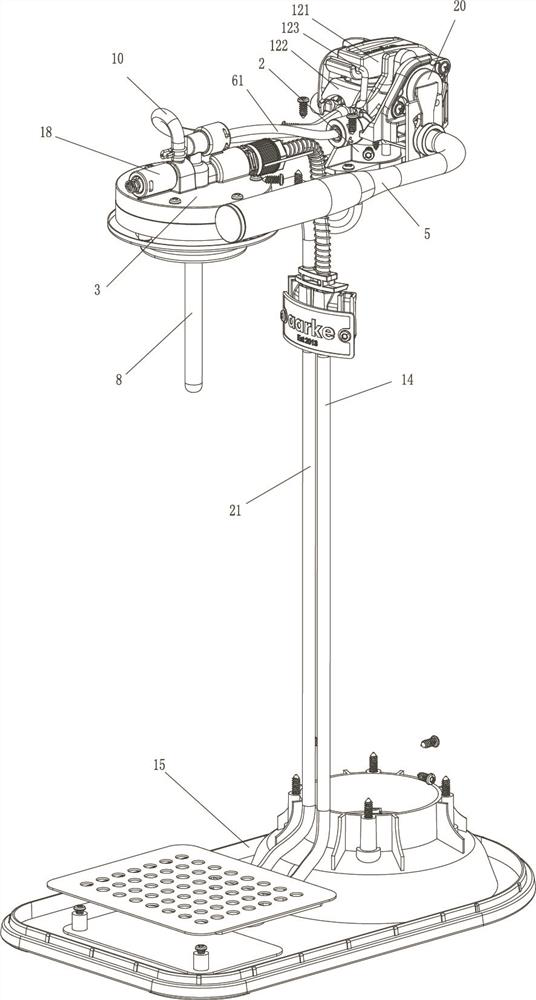

[0036] refer to Figure 1-10As shown, a multi-channel exhaust bubble water machine, the main body of the bubble water machine is mainly composed of a first shell 24, a second shell 25, a connecting shell 26, a third shell 27 and a lower base 15, the lower base 15 As a whole supporting base, the third casing 27 is vertically arranged on the supporting base and can be dismantled for placing gas cylinders. The first casing 24 is installed on the upper end of the third casing 27 and is connected to the first casing 24 through the connecting casing 26 . The bubble water machine also includes: a main base 1, on which an exhaust base 2 and an air intake base 3 are provided, the components are directly connected by screws, and the exhaust base 2 is placed on the first In a casing 24, the air intake base 3 is placed in the second casing 25; the exhaust control unit 12 is movably mounted on the main base 1 and placed above the exhaust base 2; the ejector pin 4 is movable Installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com