Ultrasonic tonometer

An ultrasonic and tonometer technology, applied in the directions of sonic diagnosis, infrasound diagnosis, ultrasonic/sonic/infrasound equipment control, etc., can solve problems such as corneal flattening, ultrasonic irradiation of the inspected eye, and ultrasonic irradiation of difficult corneas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

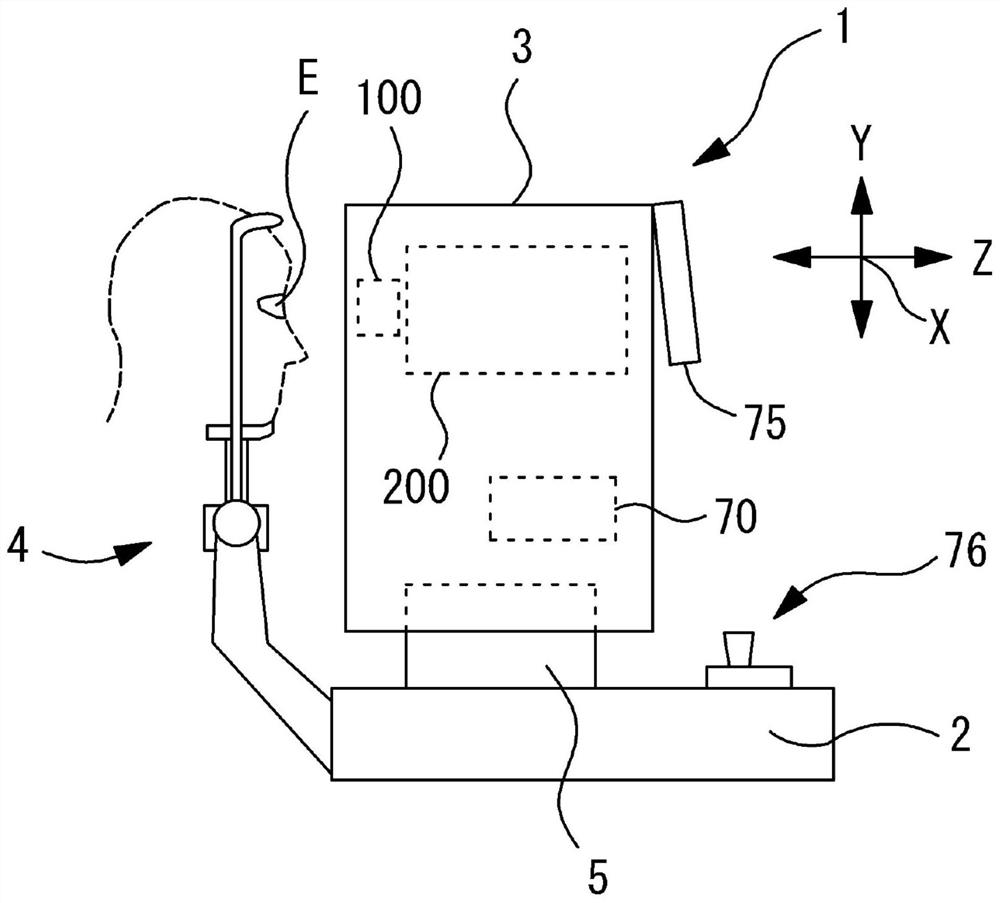

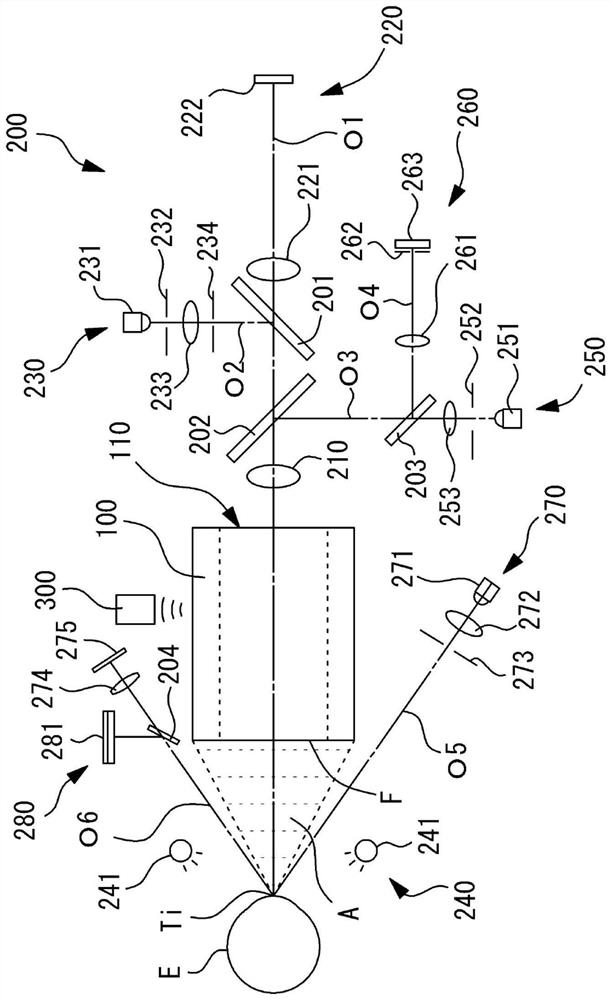

[0021] Hereinafter, the first embodiment according to the present disclosure will be described. The ultrasonic tonometer of the first embodiment measures the intraocular pressure of the subject's eye in a non-invasive manner. The ultrasonic tonometer measures the intraocular pressure of the eye to be examined based on, for example, a change in the shape of the cornea when the eye is irradiated with ultrasound or a reflected wave of the ultrasound from the eye to be examined.

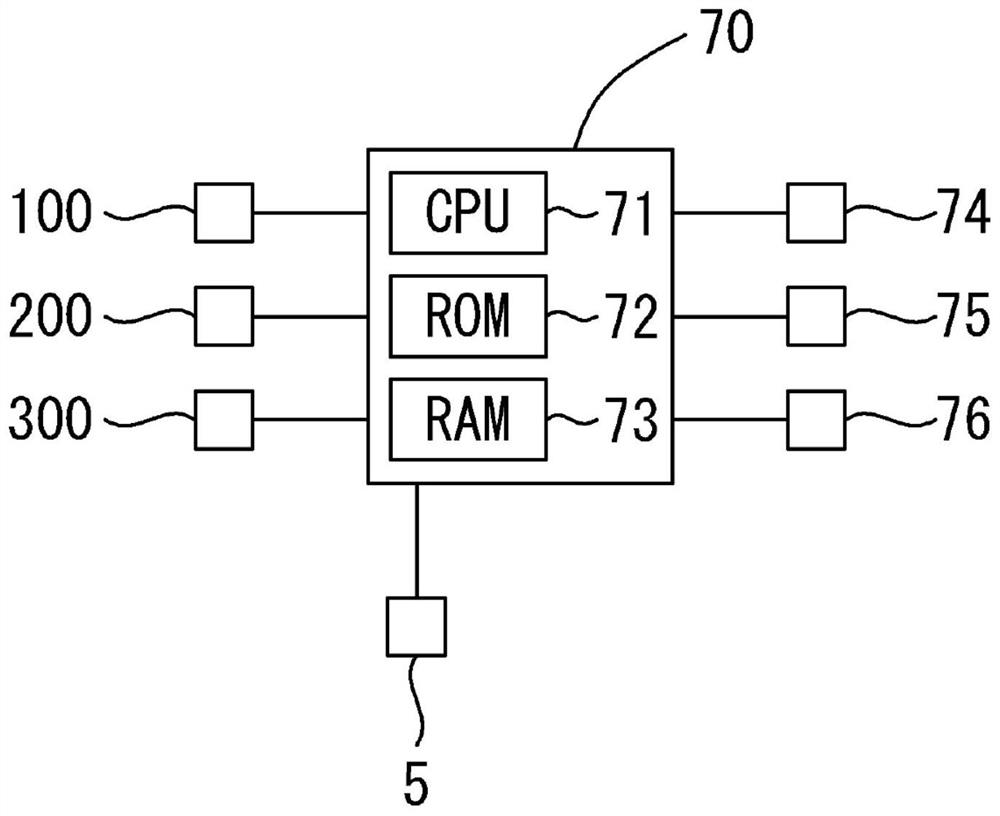

[0022] The ultrasonic tonometer includes, for example, an ultrasonic generating unit (for example, the ultrasonic unit 100 ), a detecting unit (for example, the detecting unit 300 ), and a control unit (for example, the control unit 70 ). The ultrasonic generating unit has, for example, a vibrator, and generates ultrasonic waves toward the subject's eye. The detection unit detects, for example, the output of the ultrasonic wave generation unit. The detection unit detects, for example, ultrasonic waves,...

no. 2 Embodiment approach >

[0036] Hereinafter, a second embodiment according to the present disclosure will be described. The ultrasonic tonometer according to the second embodiment includes, for example, an ultrasonic generation unit, a deformation detection unit (deformation detection system 260 ), and a control unit. The ultrasonic generation unit generates ultrasonic waves toward the subject's eye. The deformation detection unit detects the deformation state of the cornea. The deformation detection unit optically detects the deformation state of the cornea, for example. For example, the deformation detection unit may be set so that the intensity of the detection signal becomes maximum when the cornea is deformed into a predetermined shape. In addition, the deformation detection unit can detect the deformation state of the cornea from the captured image. The deformation detection unit outputs a detection signal corresponding to the detection result. The control unit controls the ultrasonic genera...

no. 3 Embodiment approach >

[0045] Hereinafter, a third embodiment according to the present disclosure will be described. An ultrasound tonometer according to a third embodiment includes an ultrasound generating unit and a control unit. The ultrasonic generation unit generates ultrasonic waves toward the subject's eye. The control unit controls the ultrasonic generation unit. When the ultrasonic generation unit irradiates the eye with ultrasonic waves and a predetermined irradiation time elapses, the control unit stops the irradiation of ultrasonic waves. Accordingly, the ultrasonic tonometer can reduce discomfort to the subject.

[0046] In addition, the ultrasonic tonometer may further include a deformation detection unit that detects the deformation state of the cornea of the subject's eye. The deformation detection unit outputs a detection signal corresponding to the detection result. The control unit may determine whether the cornea is deformed into a predetermined shape capable of measuring i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com