Thermal insulation spraying material and preparation process thereof

A technology of spraying material and preparation process, which is applied in dissolving, mixer, grain processing, etc., can solve the problems of low crushing efficiency and inconvenient crushing of vermiculite, etc., and achieve the effect of high crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

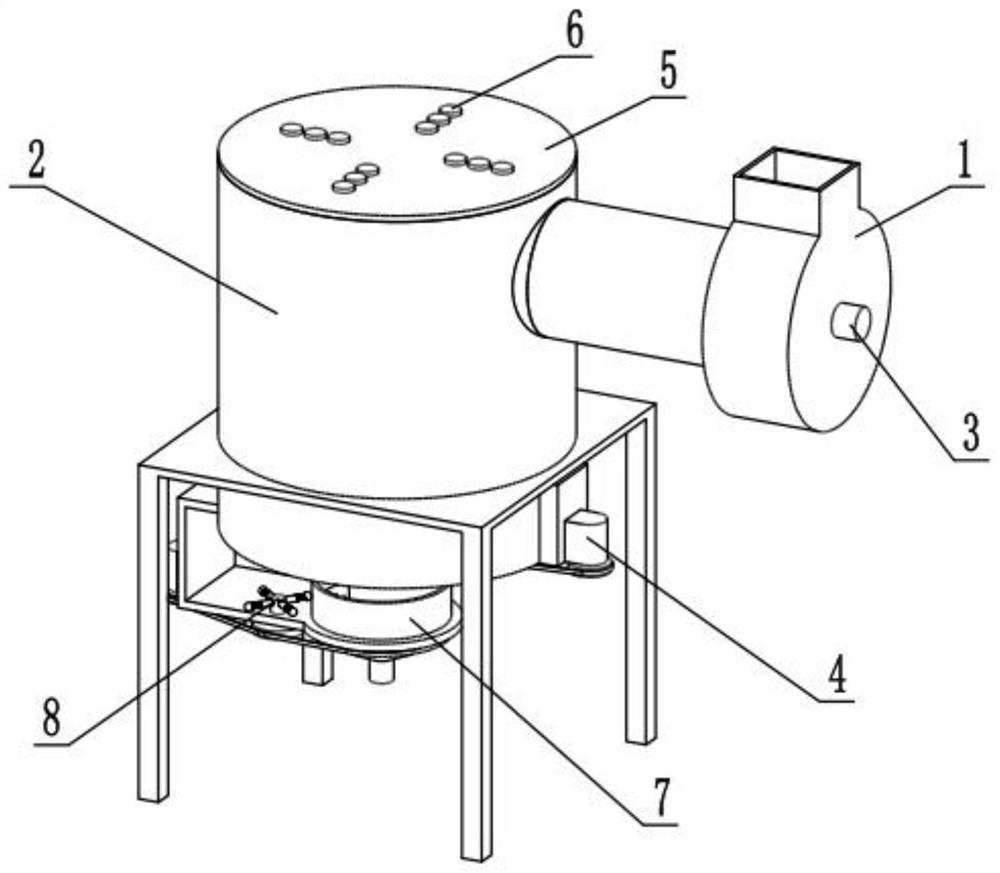

[0035] Such as Figure 1-11 Shown, a kind of thermal insulation spraying material preparation process comprises the following steps:

[0036] Step 1, crushing and screening the vermiculite;

[0037] Step 2, roasting and pulverizing the vermiculite obtained in step 1;

[0038] Step 3, mixing the vermiculite powder obtained in step 2 with other raw materials evenly to obtain a thermal insulation spraying material;

[0039] The above-mentioned heat-insulation spraying material preparation process also involves a heat-insulation spraying material preparation device;

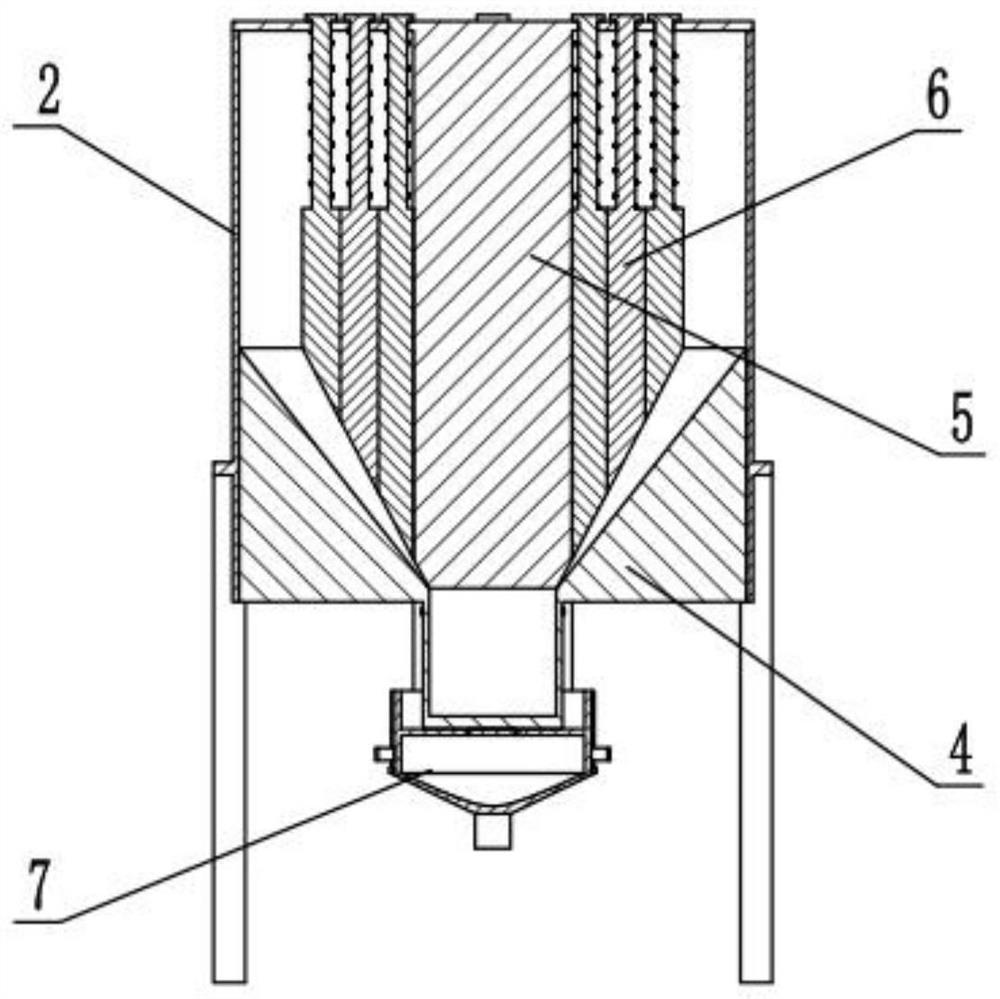

[0040] The preparation device for heat-insulating spraying materials includes a baking box frame 1, a crushing outer frame 2, a conveying mechanism 3, a crushing mechanism 4, a central fixing frame 5, an auxiliary crushing mechanism 6, a grinding mechanism 7 and a knocking vibration mechanism 8 , the roasting box frame 1 is fixedly connected to the side end of the crushing outer frame 2, the conveying mechanism 3 ...

specific Embodiment approach 2

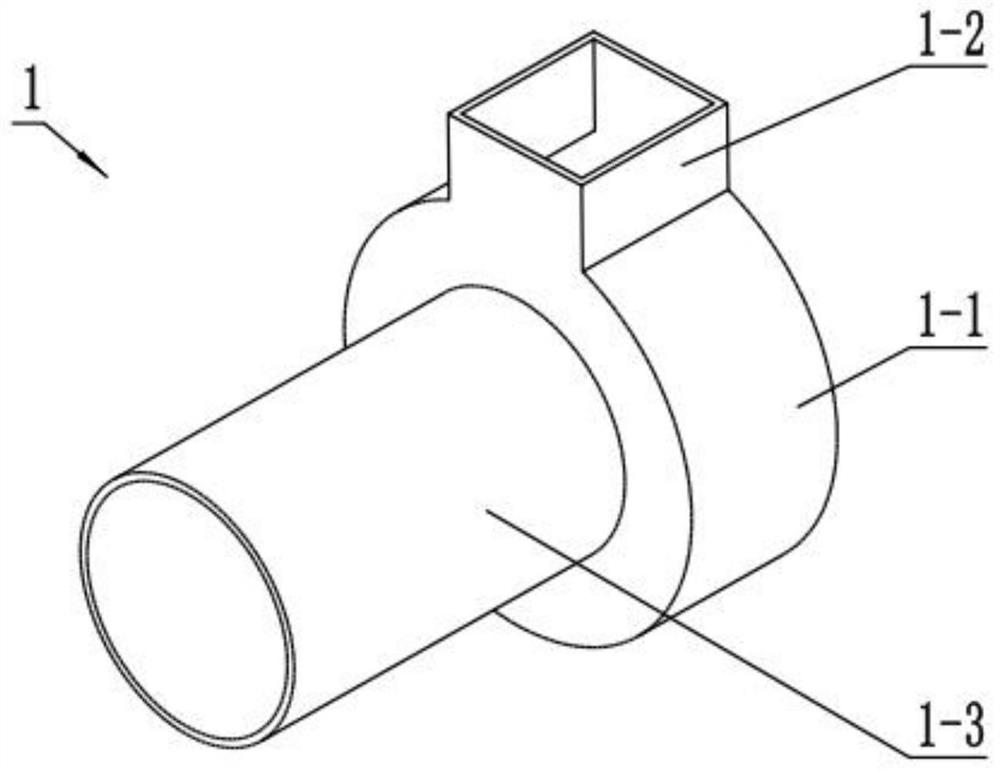

[0043] Such as Figure 1-11 As shown, the roasting case frame 1 includes a roasting case 1-1, a feed pipe 1-2 and a delivery pipe 1-3, the roasting case 1-1 is a cylindrical design, and the lower end of the roasting case 1-1 A heating device is provided, the feeding pipe 1-2 is arranged on the upper end of the roasting box 1-1, and the conveying pipe 1-3 is coaxially fixedly connected to the side end of the roasting box 1-1.

[0044] The heating device provided at the lower end of the roasting box 1-1 is used to heat the vermiculite to make the vermiculite lose water and expand.

specific Embodiment approach 3

[0046] Such as Figure 1-11 As shown, the upper crushing outer frame 2 includes a main pipe 2-1, a connecting port 2-2, a leg frame 2-3, an L-shaped connecting plate 2-4, a mounting plate 2-5 and a motor base 2-6, The outer end of the main pipe 2-1 is fixedly connected with the outrigger frame 2-3, the side end of the upper part of the main pipe 2-1 is provided with a connecting port 2-2, and the L-shaped connecting plate 2-4 is fixedly connected with the lower end of the main pipe 2-1 , the mounting plate 2-5 is fixedly connected to the lower end of the L-shaped connecting plate 2-4, the side end of the lower end of the main pipe 2-1 is provided with a motor seat 2-6, and the delivery pipe 1-3 is fixedly connected to the connection port 2-2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com