Preparation method of flame-retardant corrugated board

A technology for corrugated cardboard and flame retardant coating, which is applied in spray booths, special surfaces, spray devices, etc., can solve the problems of low production efficiency of flame retardant corrugated cardboard, cumbersome flame retardant coating process, lack of flame retardant coating, etc., to achieve convenient and continuous Spray processing, easy to spray flame retardant paint, avoid the effect of burning danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

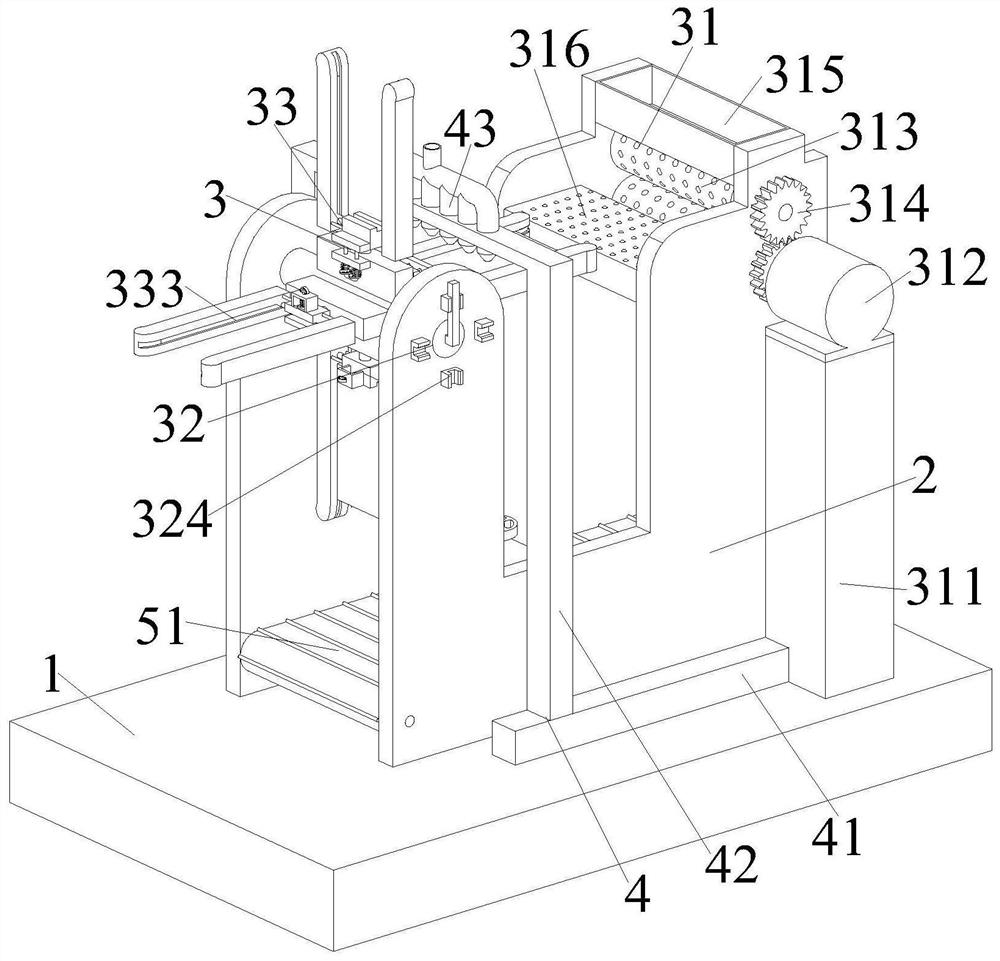

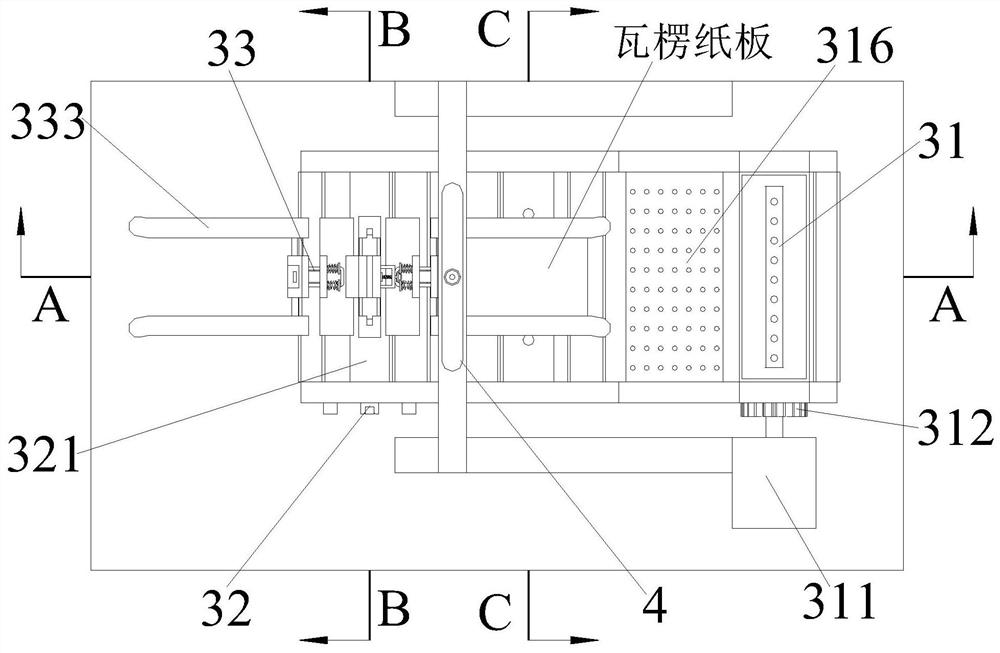

[0042] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination figure 1 to Figure 10 , to further elaborate the present invention.

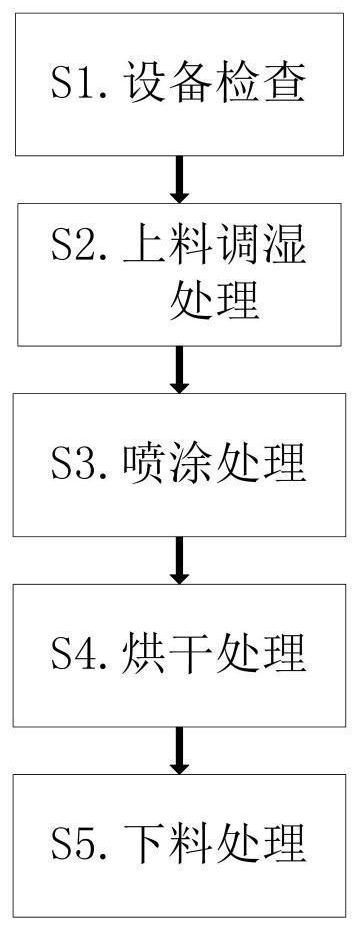

[0043] A method for preparing flame-retardant corrugated cardboard, the specific preparation method is as follows:

[0044] S1. Equipment inspection: check the flame-retardant corrugated cardboard production equipment before using it to make flame-retardant corrugated cardboard;

[0045] S2. Loading and humidity control treatment: After the equipment inspection, manually place the corrugated cardboard to be processed on the material feeding and humidity control device 3, so that the material loading and humidity control device 3 performs material feeding and humidity control on the corrugated cardboard to be processed;

[0046] S3. Spraying treatment: after the material of the corrugated cardboard is adjusted in humidity, the flame-retardant coa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap