Automatic strapping device and automatic strapping method for copper rods

A technology of automatic bundling and copper rods, which is applied in the directions of bundling materials, automatic packaging control, and parts of bundling machinery, etc., can solve the problems of time-consuming and laborious copper rods, difficult to lift and transport, and coils are easy to cross each other, so as to reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

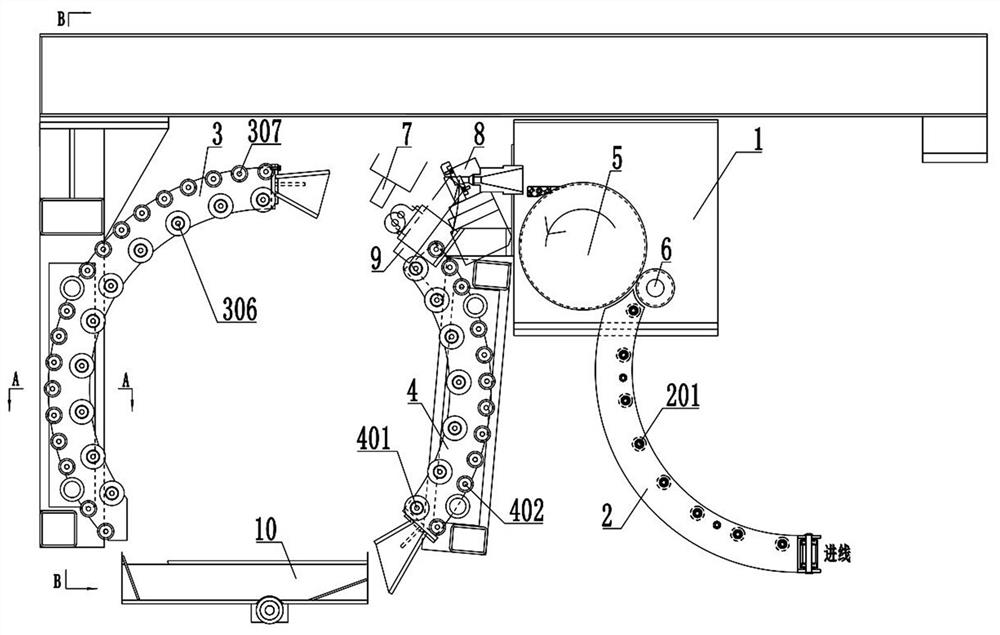

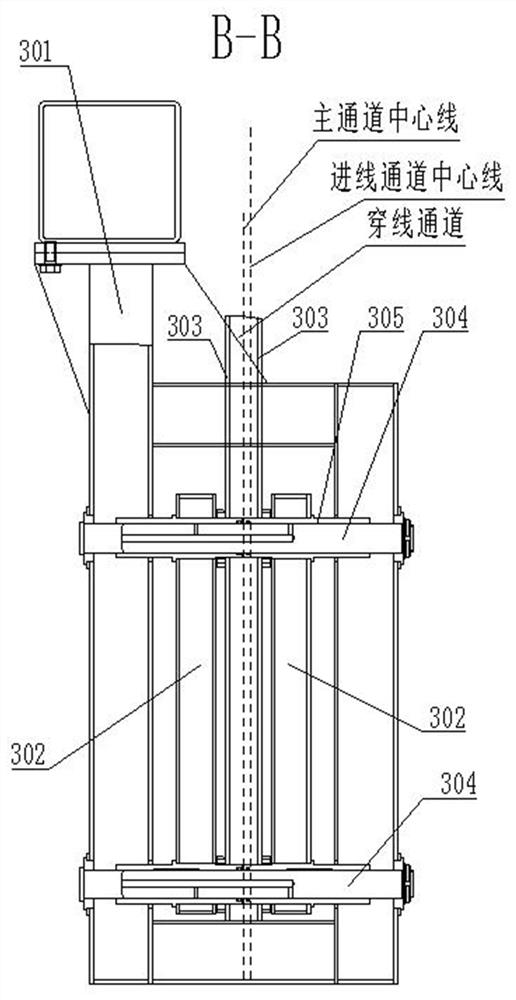

[0040] Such as Figure 1-5 Shown:

[0041] The present invention provides an automatic binding device for copper rods, including a fixing frame 1, a threading channel and a controller, wherein:

[0042] The threading channel includes an inlet channel 2 for guiding copper rods, a main channel 3 and a secondary channel 4;

[0043] A traction wheel 5 for pulling copper rods is provided between the wire inlet passage 2 and the main passage 3;

[0044] An encoder 6 for measuring the length of the copper rod is provided at the outlet of the inlet channel 2;

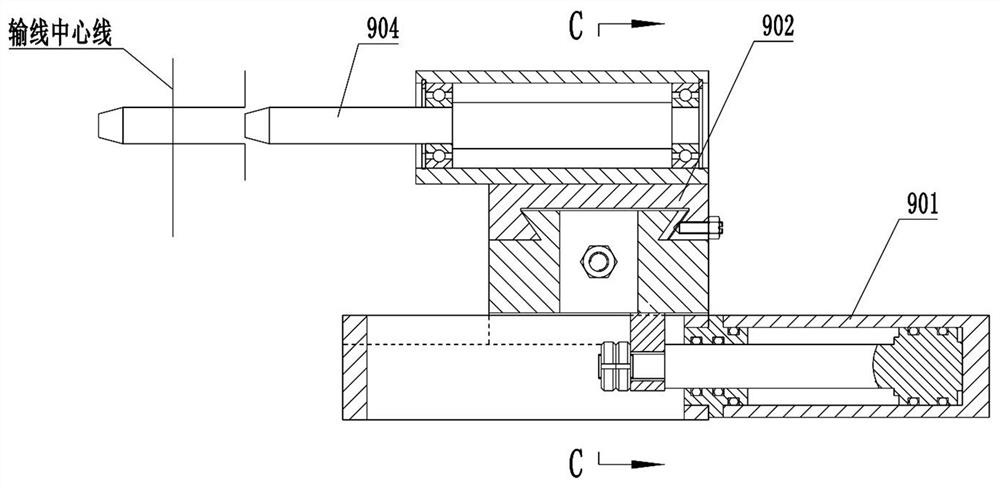

[0045] A crimping device 9 for separating the head of the copper rod is also provided between the traction wheel 5 and the main channel 3;

[0046] The traction pulley 5, the encoder 6 and the crimping device 9 are all ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com