Circuit board conveying device

A conveying device and circuit board technology, applied in packaging, conveyors, conveyor objects, etc., can solve the problems of large size, unable to meet the space occupied by the conveying table, unable to adapt to the transmission requirements of circuit boards of different specifications, etc., to reduce the occupation. the effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

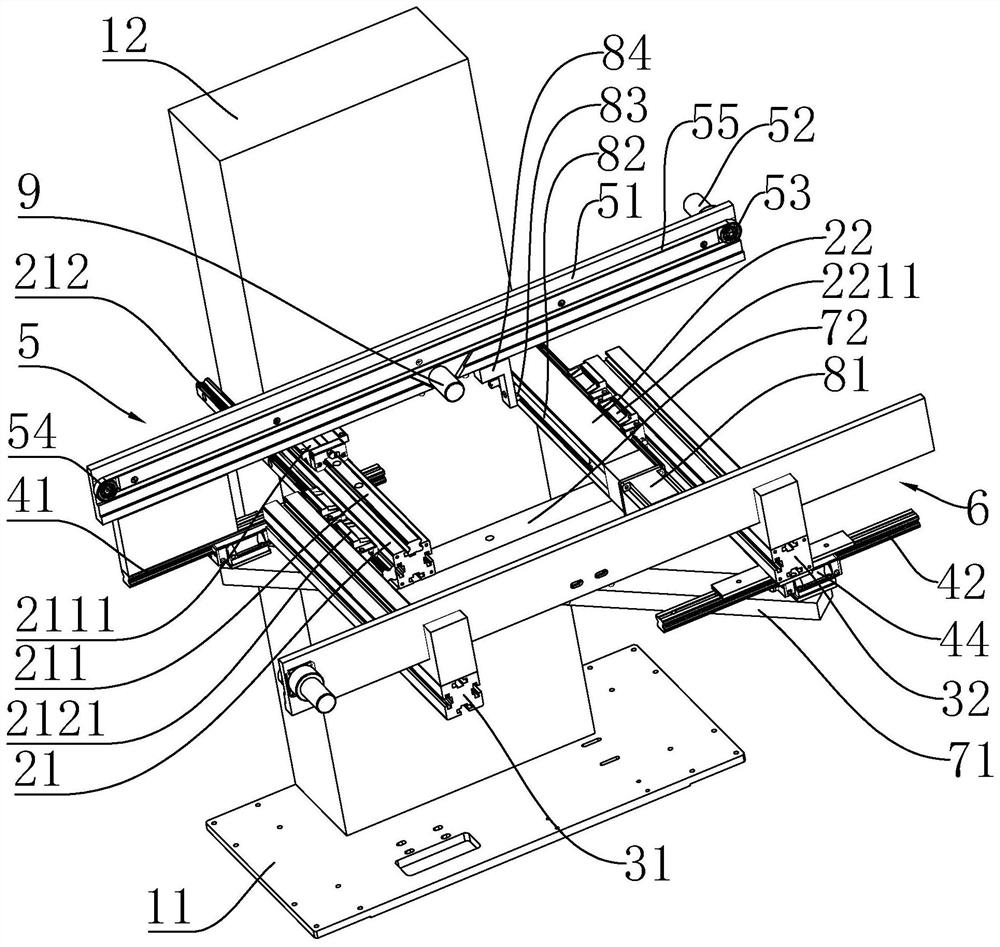

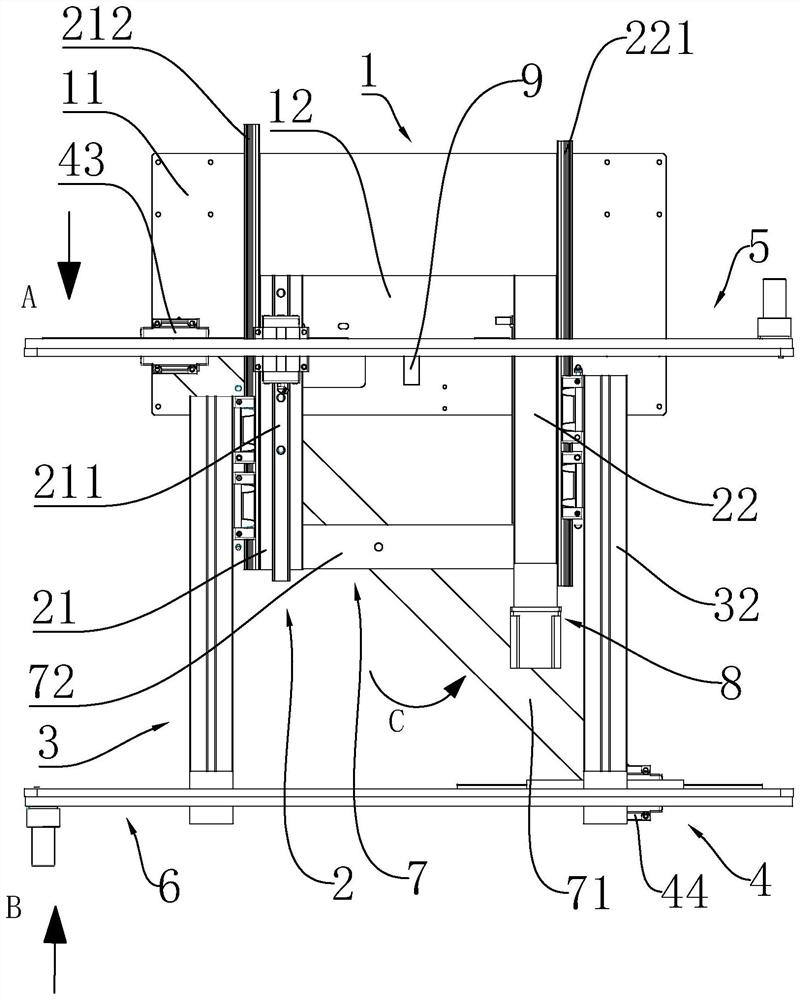

[0026] The following is attached figure 1 , 2 The application is described in further detail.

[0027] Such as figure 1 , 2 As shown, a circuit board conveying device includes a bracket 1, a first sliding device 2, a second sliding device 3, a third sliding device 4, a first conveyor belt assembly 5, a second conveyor belt assembly 6, and a linkage device 7 and drive mechanism 8.

[0028] The bracket 1 includes a support 11 and a support plate 12 . The first sliding device 2 comprises a first carriage 21 and a second carriage 22 vertically connected to the support plate 12, the first carriage 21 and the second carriage 22 are arranged horizontally and in the same plane, the first carriage 21 The upper slide is connected with the first conveyor belt assembly 5 parallel to the support plate 12, the second carriage 22 is provided with a drive mechanism 8, the first conveyor belt assembly 5 is connected with the drive mechanism 8 that drives its sliding, the first conveyor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com