Power cable storage device in power field

A power cable and storage device technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of low work efficiency, heavy power cables, time-consuming and labor-consuming manual storage of power cables, etc. Problems, to achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

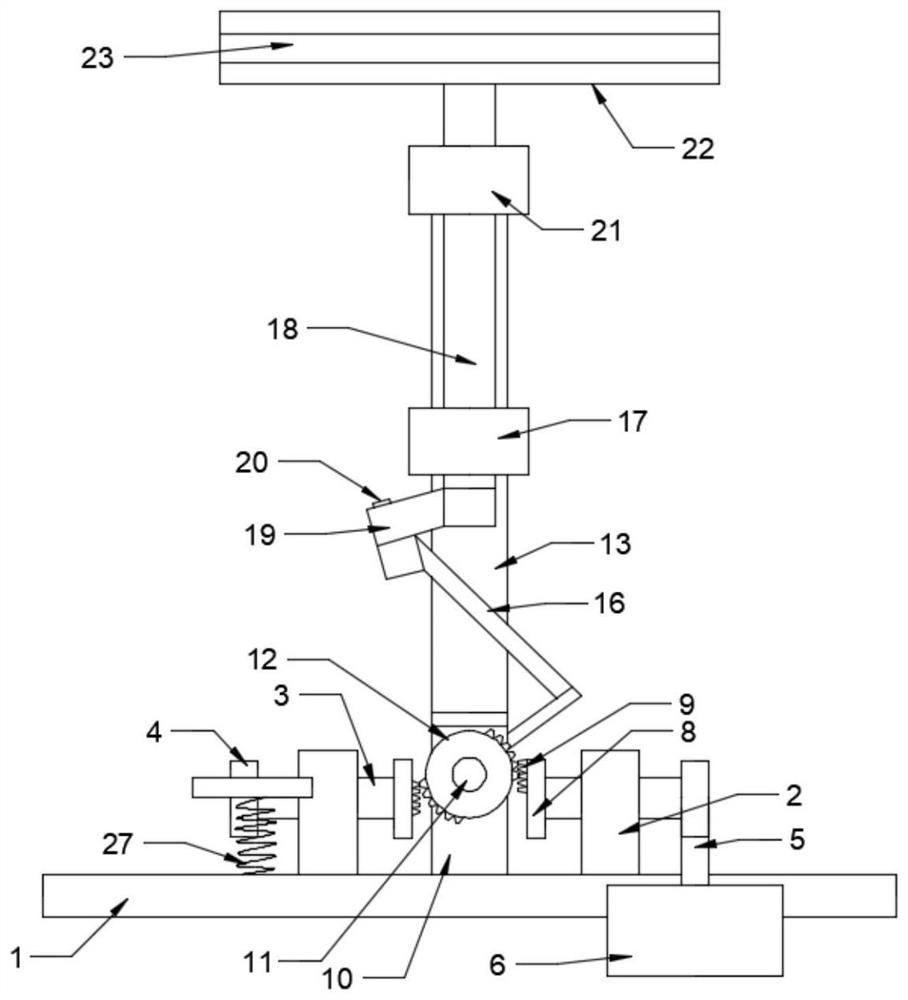

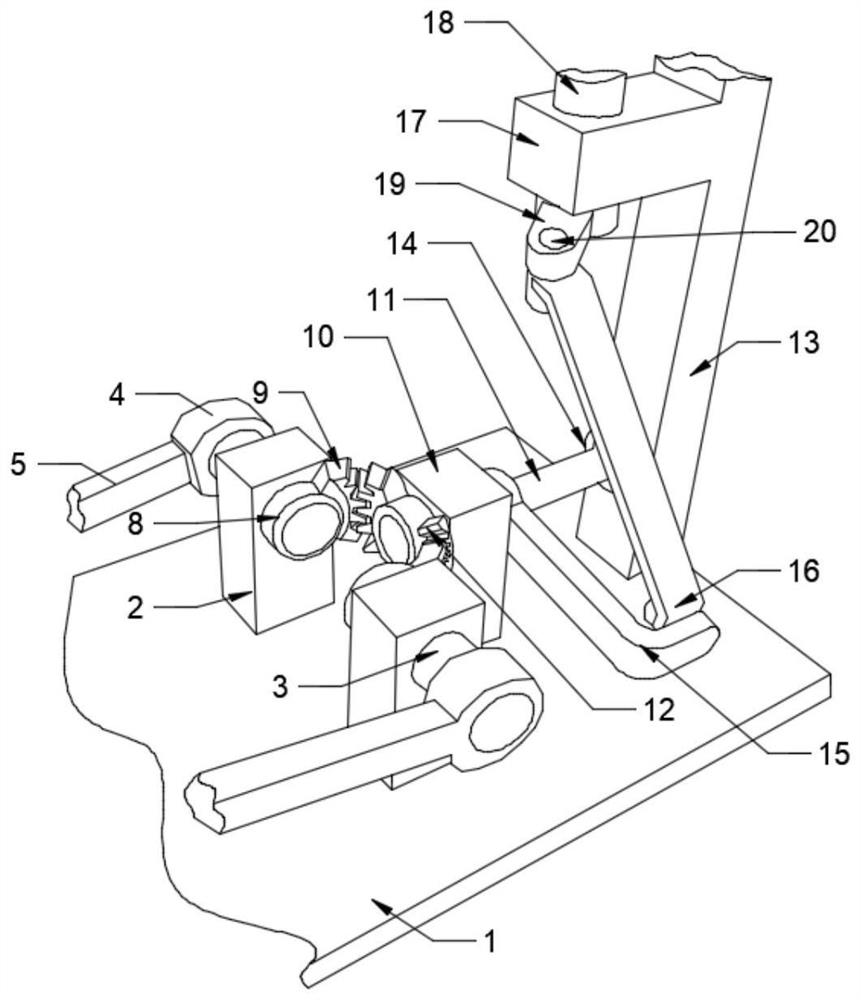

[0025] see Figure 1-5 , in an embodiment of the present invention, a power cable storage device for the electric power field, comprising: a base 1 on which a first support 2 is fixed, and a first rotating rod 3 penetrates inside the first support 2 , One end of the first rotating rod 3 is fixed with a first rotating connecting block 4, the first rotating connecting block 4 is fixedly connected with a first connecting rod 5, and the other end of the first connecting rod 5 is fixedly connected with a pedal 6, The first rotating connection block 4 runs through the other end of the first pillar 2 and is fixed with a turntable 8, and the arc-shaped rack 9 is fixedly installed on the turntable 8; the second pillar 10 is fixed on the base 1 at the same time, and the first The inside of the two pillars 10 is penetrated with a second rotating rod 11, and one end of the second rotating rod 11 passing through the second pillar 10 is fixedly installed with a first bevel gear 12, and the ...

Embodiment 2

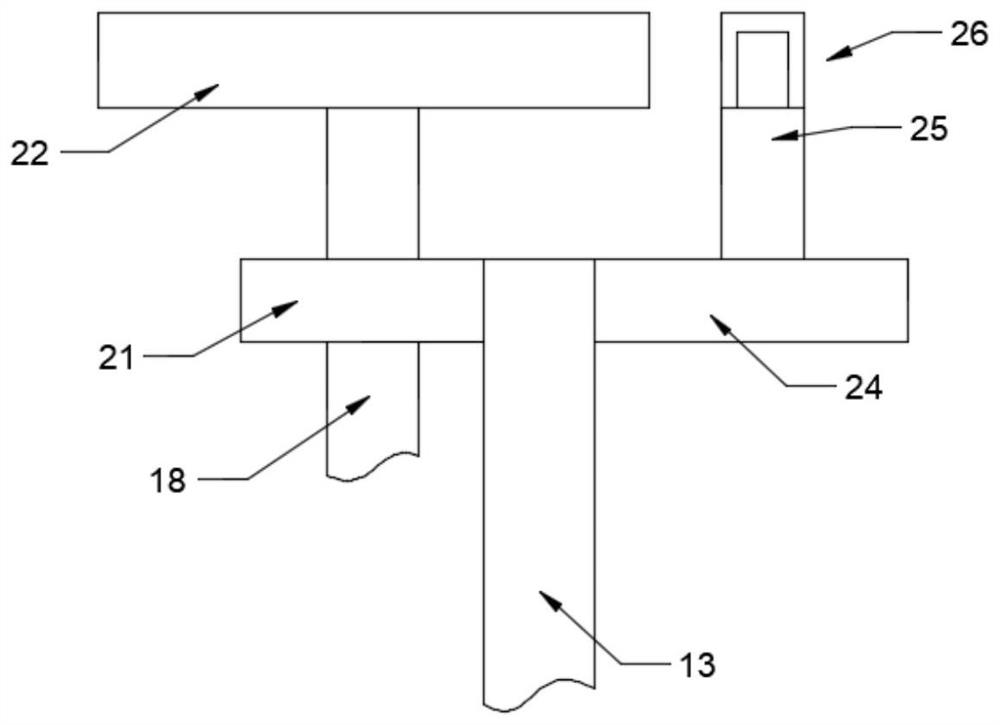

[0031] see Figure 1-5 , in this embodiment, the cable storage and cutting mechanism 26 includes: an outer frame 2601, a first chute 2602 and a second chute 2603 are arranged inside the outer frame 2601, and the first chute 2602 and the second chute A first slide plate 2606 and a second slide plate 2608 are slidably installed inside the chute 2603 respectively, and a first cutter 2607 and a second cutter 2609 are fixedly installed on the upper parts of the first slide plate 2606 and the second slide plate 2608 respectively, and the first slide plate 2606 An inner frame 2604 is fixedly connected to the lower side, a rack 2605 is fixed on one side of the inner frame 2604, a transmission shaft 2614 is arranged inside the outer frame 2601, and a second bevel gear 2613 is connected to the end of the transmission shaft 2614, The third bevel gear 2612 and the fourth bevel gear 2615 are respectively meshed on both sides of the second bevel gear 2613, and the third bevel gear 2613 and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap