A high-pressure jetting anchor cable drill body and its construction technology

A high-pressure rotary grouting and drill body technology, which is applied in infrastructure engineering, construction, excavation, etc., can solve the problems of easily increasing the initial settlement of the stratum outside the foundation pit, the large disturbance leaves of the free section and the non-effective anchoring section, and the influence of the stratum. , to achieve the effect of increasing connection stability, improving drilling efficiency and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

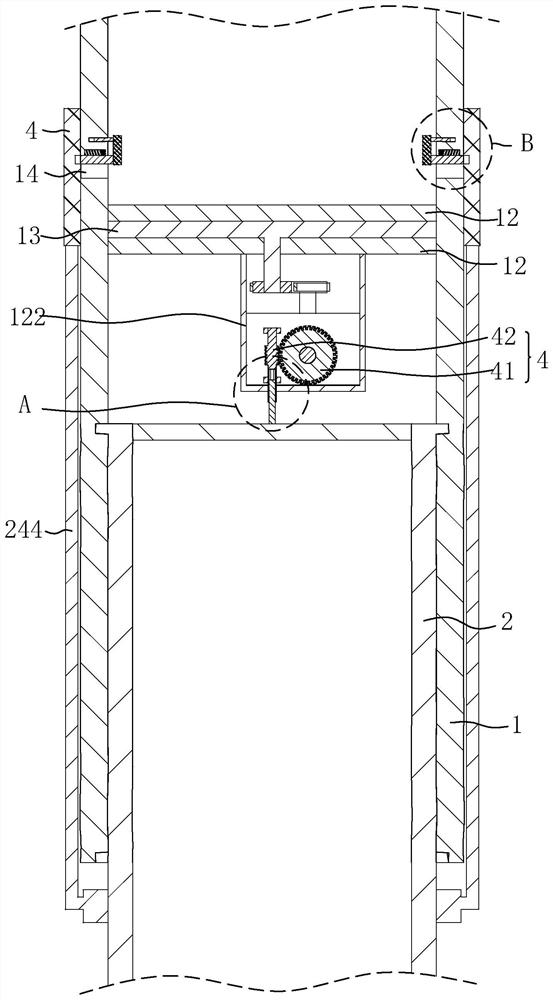

[0045] Attached to the following Figure 1-6 This application will be described in further detail.

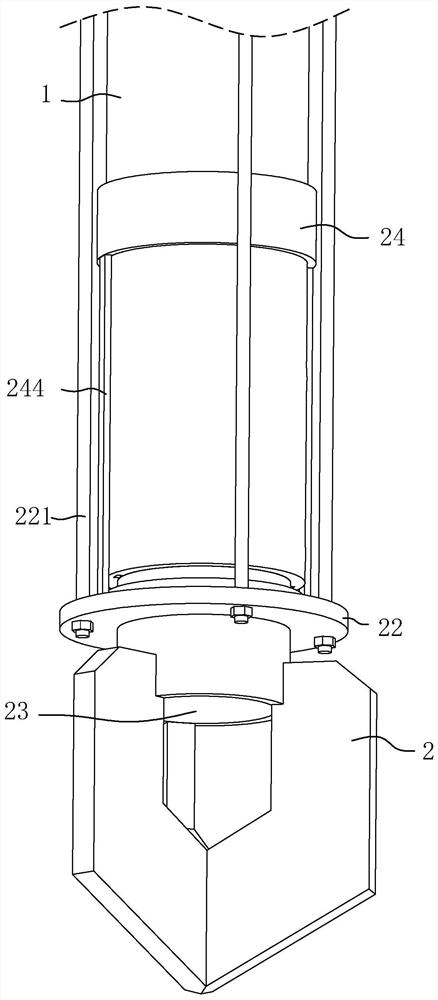

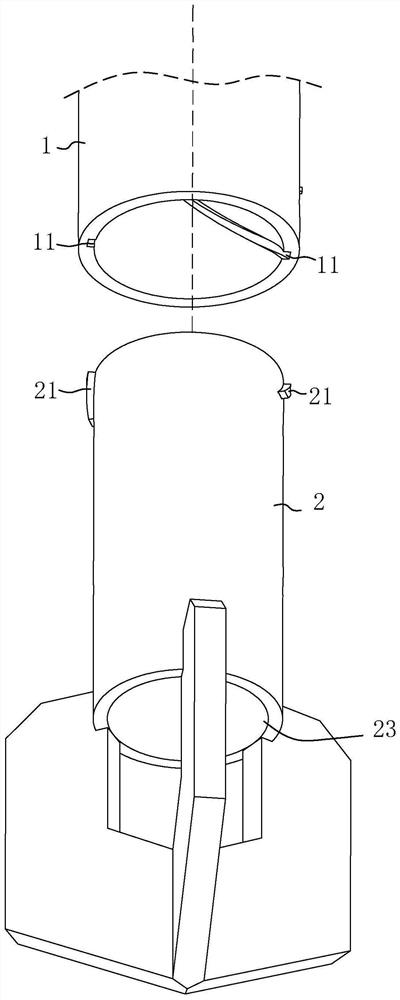

[0046] The embodiment of the present application discloses a high-pressure rotary jetting anchor drill body. combine figure 1 and figure 2 , a high-pressure rotary jet anchor drill body includes a hollow rotary jet drill rod 1, one end of the rotary jet drill rod 1 is detachably connected with a drill bit 2, and the drill bit 2 is hollow and one end away from the rotary jet drill rod 1 is provided with a constant The slurry outlet 23 is pressed out; the drill pipe of the drill bit 2 is sleeved with a pressure bearing plate 22 , and a steel strand 221 is fixedly connected to the pressure bearing plate 22 .

[0047] When in use, the rotary jet drill rod 1 rotates to drive the drill bit 2 to rotate, and the rotary jet drill rod 1 drives the drill bit 2 to perform drilling operations. During the drilling process, the cement slurry is injected into the rotary jet drill pipe 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com