Tool type structure construction joint rapid retaining construction method

A construction method and a technology of construction joints, which are applied to building structures, formwork/formwork/work frames, and on-site preparation of building components, and can solve problems such as difficulty in construction quality control, uneven construction joints, and poor construction efficiency , to achieve high construction efficiency, construction quality assurance, and improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

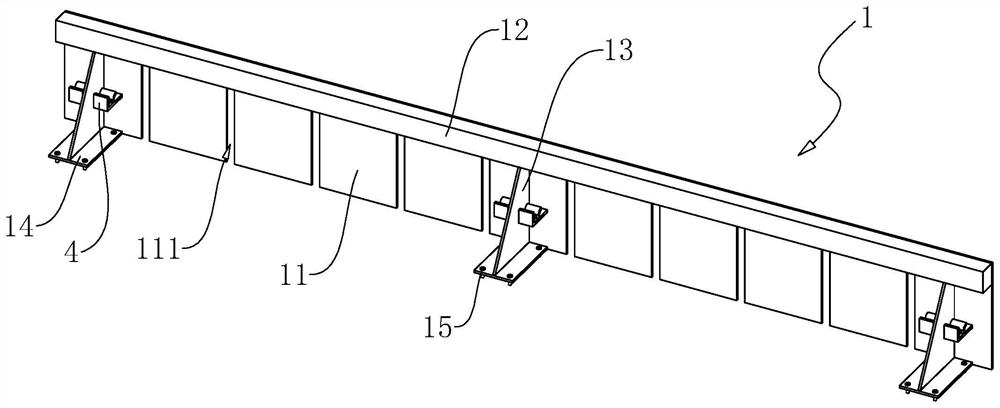

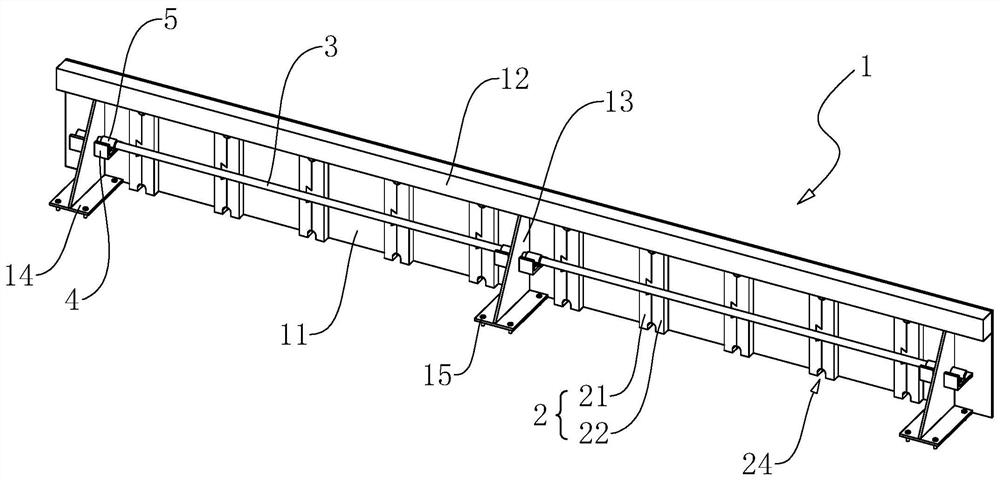

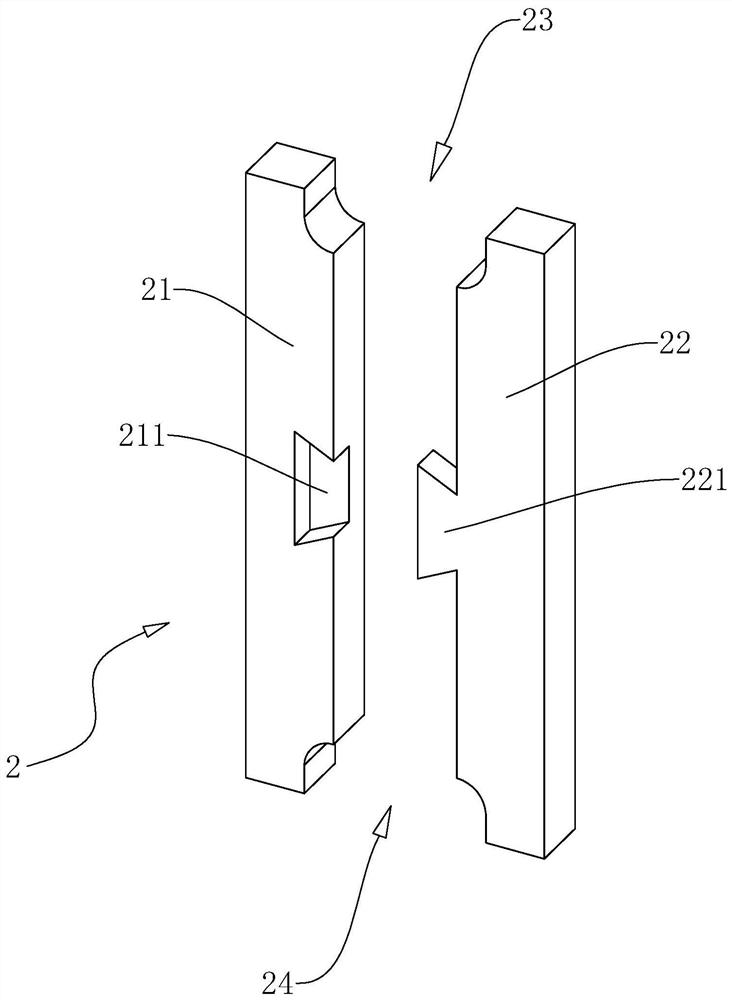

[0045] The following is attached Figure 1-5 The application is described in further detail.

[0046] The embodiment of the present application discloses a steel mold barrier 1 . refer to figure 1 , the steel mold barrier 1 includes a barrier panel 11 and an upper main flute 12. In the embodiment of the present application, the barrier panel 11 adopts a galvanized steel plate with a thickness of 3 mm, and the upper main flute 12 adopts a galvanized square tube with a wall thickness of 3 mm. , the upper main flute 12 is welded to the upper edge of the partition panel 11 along the length direction of the partition panel 11, and the upper main flute 12 is located on the side of the partition panel 11 facing away from the area where concrete needs to be poured, and the top surface of the upper main flute 12 It is flush with the upper edge of the partition panel 11 to strengthen the integral rigidity of the partition panel 11 .

[0047] refer to figure 1 The steel mold barrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com