Cylinder body and pump/motor/air compressor/internal combustion engine using same

A technology for internal combustion engines and air compressors, applied in the field of pumps/motors/air compressors/internal combustion engines, which can solve problems affecting air tightness, lack of simple mechanisms, and low compression ratios, and achieve high manufacturing costs, strong versatility, and The effect of high working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] refer to Figure 11 to Figure 14 , the present embodiment 1 provides a pump / motor / air compressor, its components include: cylinder 1, main shaft 2, blade 30, first sealing sheet 31 and second sealing sheet 32, and front cover 4 and rear cover 5.

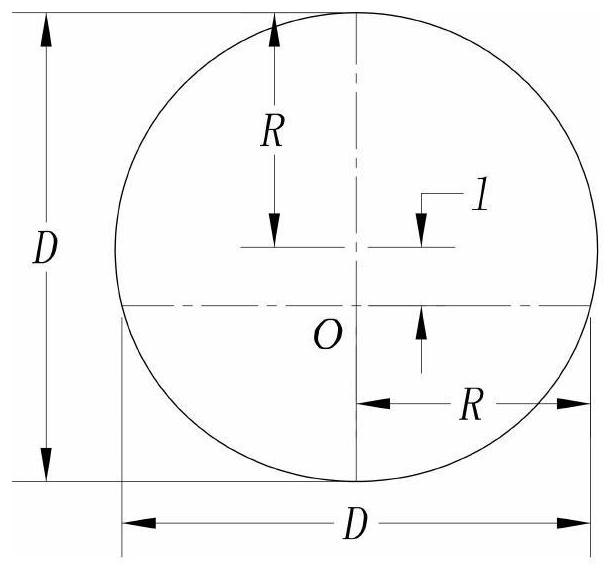

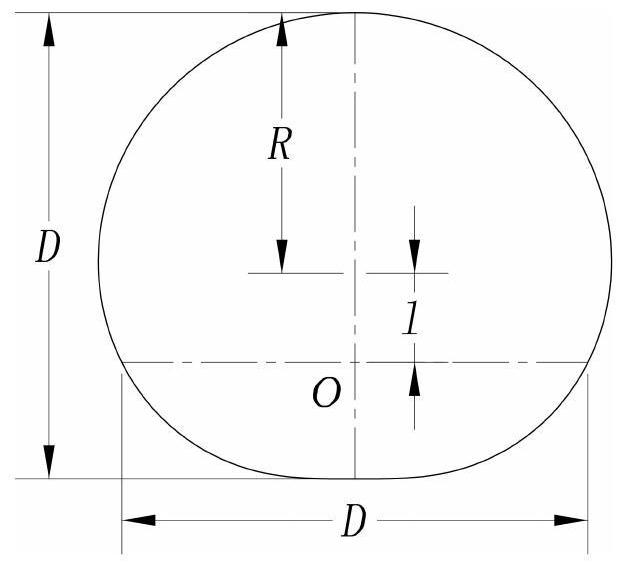

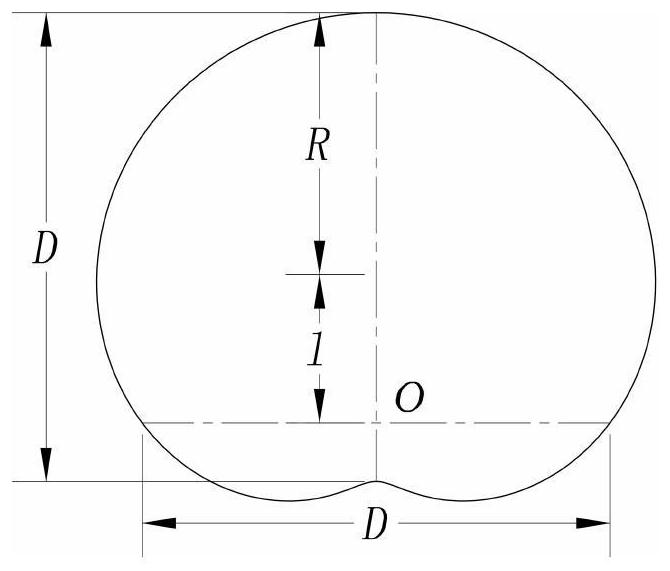

[0068] Cylinder 1 includes a cylinder hole, the wall of the cylinder hole is a cylinder, and the contour curve of the positive section of the cylinder hole is given by figure 2 The determined isometric curve.

[0069] The axis of the main shaft 2 is a straight line, the axis of the main shaft 2 is the center of rotation of the contour curve of the cylinder hole, the front end of the main shaft 2 extends into the cylinder hole, and the diameter of the front end of the main shaft 2 is equal to the minimum distance from the center of rotation to the isometric curve, That is, the cylindrical surface at the front end of the main shaft 2 is in tangential contact with the cylinder bore wall. The diameter of the front end of the m...

Embodiment 2

[0079] refer to Figure 15 to Figure 18 , the present embodiment 2 provides a single-cylinder internal combustion engine, its component parts include: cylinder block 1, main shaft 2, blade 30, first sealing sheet 31 and second sealing sheet 32, and front cover 4 and rear cover 5. Wherein, the blade 30 , the first sealing sheet 31 and the second sealing sheet 32 together form a slider rotor.

[0080] Cylinder 1 includes a cylinder hole, the wall of the cylinder hole is a cylinder, and the contour curve of the positive section of the cylinder hole is given by figure 2 The determined isometric curve.

[0081] The axis of the main shaft 2 is a straight line, the axis of the main shaft 2 is the center of rotation of the contour curve of the cylinder body hole, the front end of the main shaft 2 extends into the cylinder body hole, and the diameter of the front end of the main shaft 2 is smaller than the minimum distance from the center of rotation to the isometric curve. The fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com