Magnesium alloy multi-pass forming process design method based on fine grains

A technology of forming process and design method, applied in the field of fine-grained magnesium alloy multi-pass forming process design, can solve problems such as low efficiency and poor accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

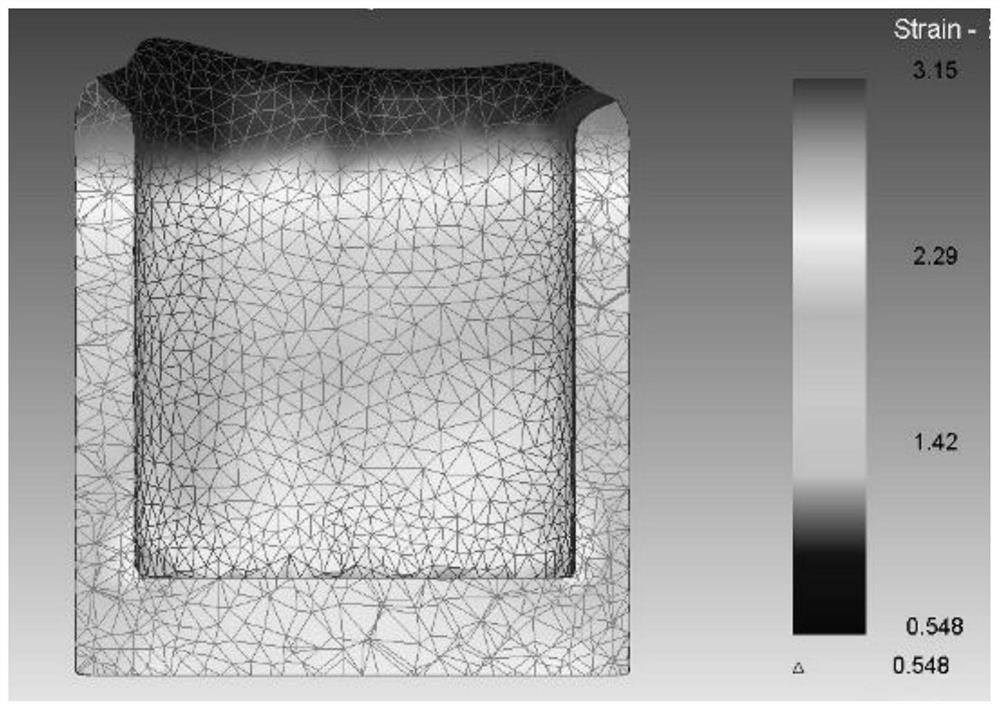

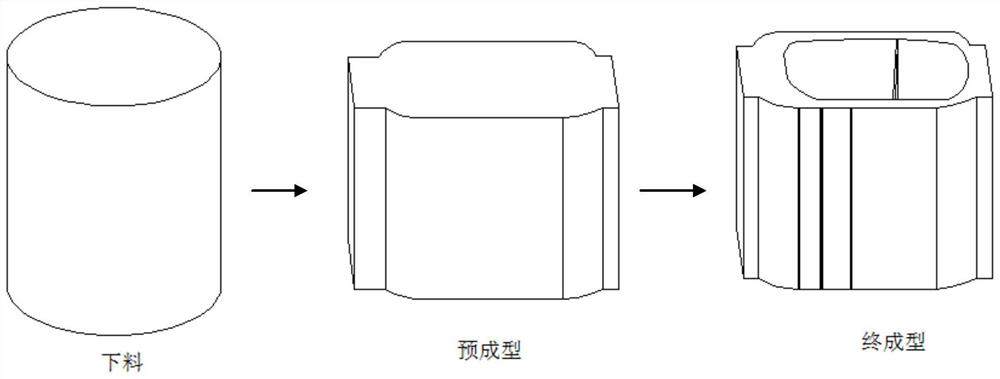

[0017] A fine-grain-based multi-pass forming process design method for magnesium alloys. Specifically, AZ80 magnesium alloy blanks are used to form special-shaped bobbin magnesium alloy components. The steps are as follows:

[0018] Step 1. Taking the initial grain size, strain amount, deformation temperature, and deformation rate of the AZ80 magnesium alloy billet as variables, and the grain size of the deformed special-shaped tube magnesium alloy component as the target, carry out the reverse extrusion orthogonal test. Different factors (Under the conditions) the grain size after back extrusion is shown in Table 1,

[0019] Table 1 Grain size after back extrusion under different factors (under conditions)

[0020] Initial grain size / μm strain / % Deformation temperature / ℃ Deformation rate / s -1

Grain size after deformation / μm 50.5 20 400 0.001 35.4 50.5 20 400 0.01 27.8 50.5 20 400 0.1 25.3 50.5 20 370 0.001 24.8 50.5 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com