Transformer with safe heat dissipation function

A transformer and safety technology, applied in the field of transformers, can solve problems affecting the safe operation of transformers, energy waste, convective expansion, etc., and achieve the effect of easy grasping and applying torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

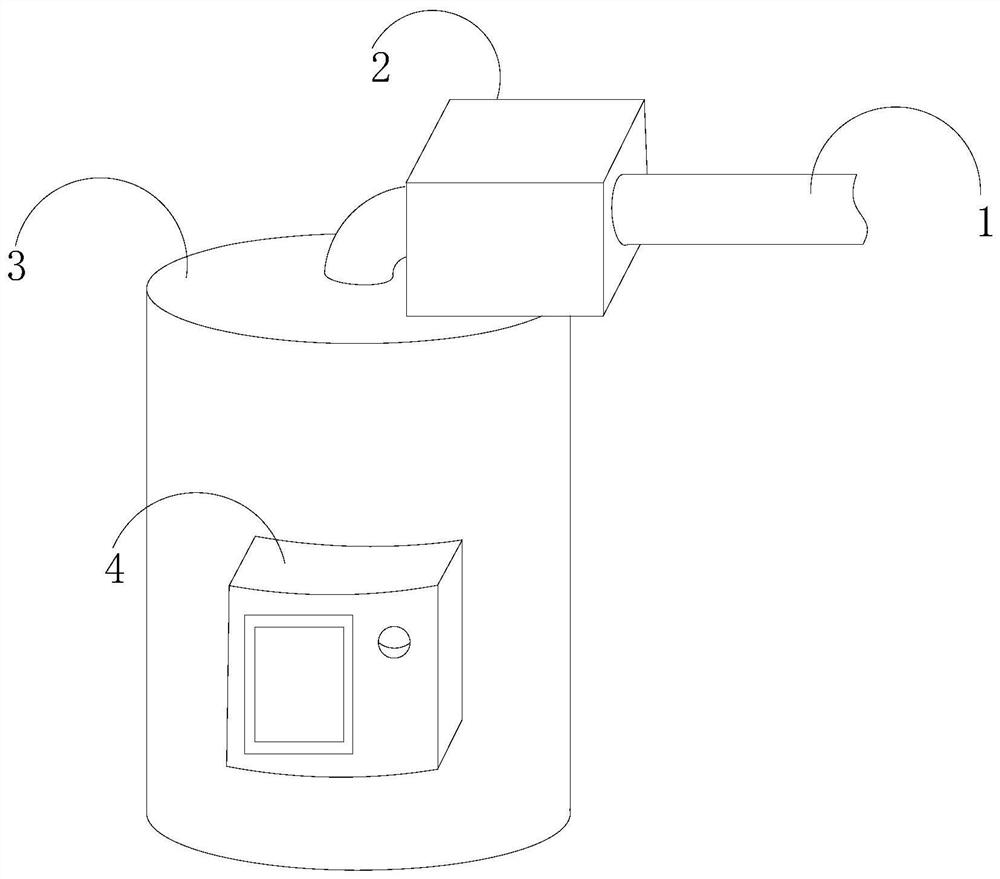

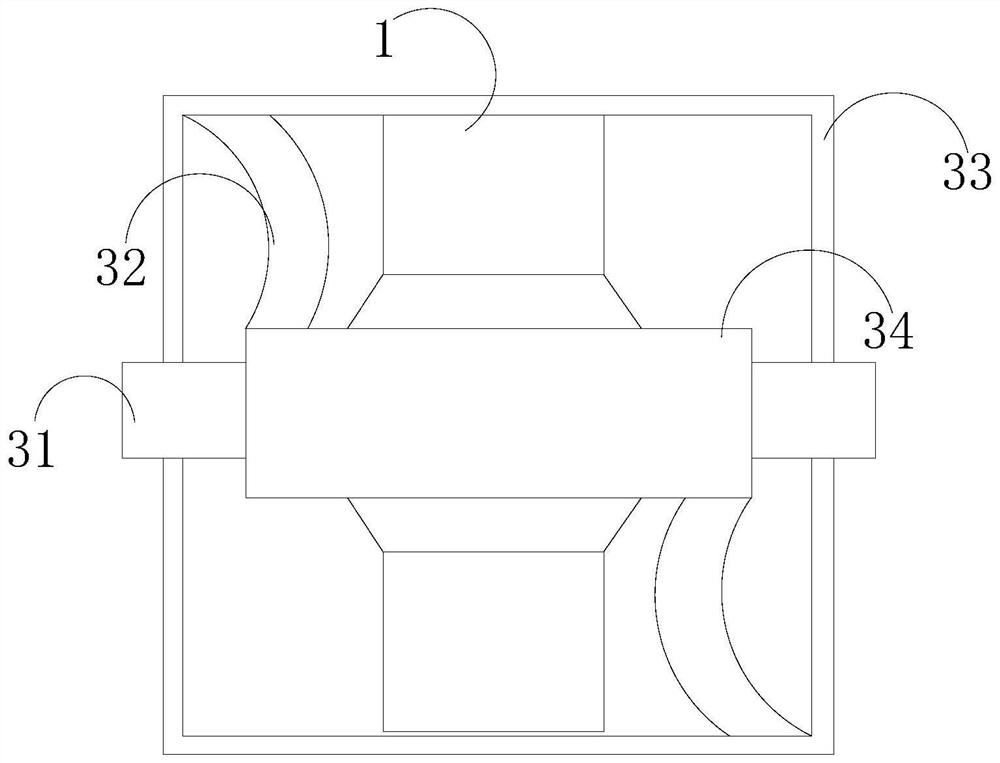

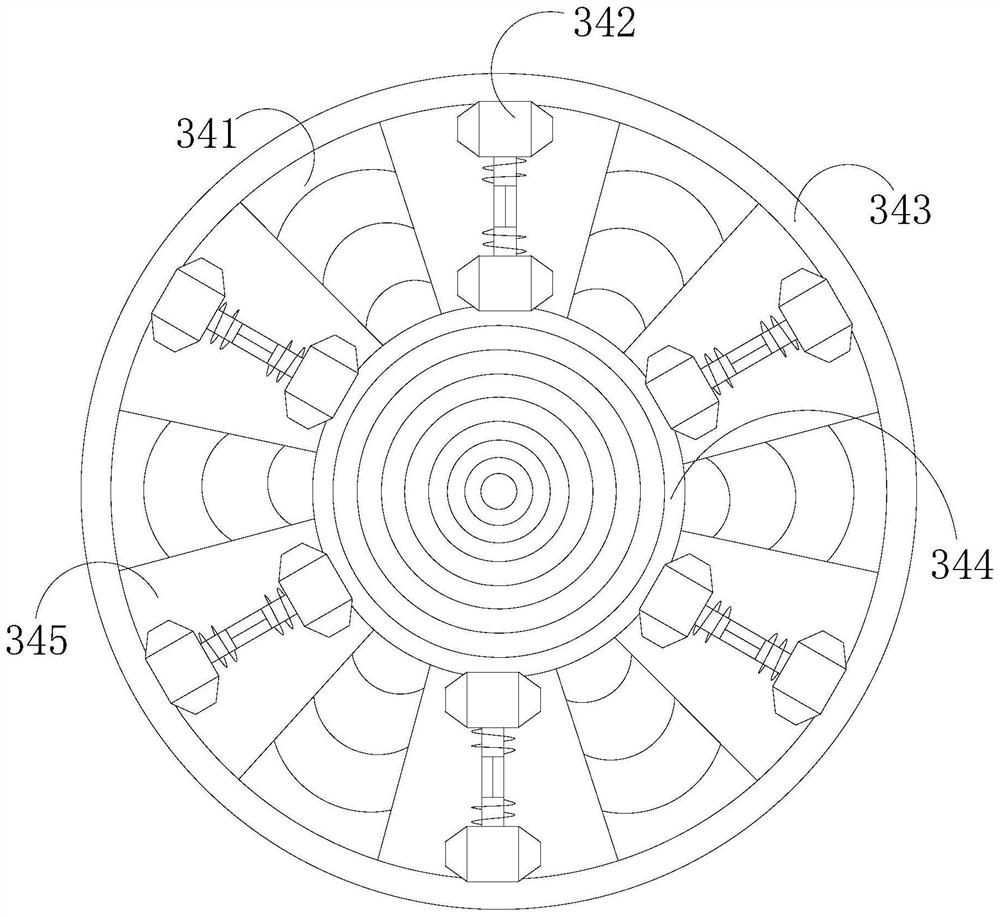

[0027] Such as Figure 1-Figure 4 As shown, the present invention provides a safe and heat-dissipating transformer, the structure of which includes a high-voltage connecting pipe 1, a driver 2, a host 3, and an operating table 4. The high-voltage connecting pipe 1 is fixedly connected to the top of the host 3 through the driver 2, and the host 3. An operating table 4 is welded on the outer surface, and the operating table 4 is electrically connected to the driver 2 to cooperate. The host 3 includes a convection tube 31, a lead support column 32, a protective frame 33, and a coil 34 , the coil 34 is installed inside the protective frame 33 through the convection tube 31, the inner wall of the protective frame 33 is welded with the convection tube 31 and the supporting column 32, and the coil 34 includes a buffer grid 341, a booster device 342, and an apron 343 , iron core 344, beveled plate 345, the buffer grid 341 is a stacked structure, indirectly fit between the rubber ring ...

Embodiment 2

[0029] Such as Figure 5-Figure 8 As shown, on the basis of Embodiment 1, the present invention combines the mutual cooperation of the following structural components. The pinning ball 21a1 is in rolling contact with the inside of the rolling cavity 21a2, the rolling cavity 21a2 is a hemispherical structure, its bottom is fixedly connected above the parallel seat 21a3, and its open end is equipped with a top structure 21a4, and the parallel seat 21a3 is circumscribed with a circular socket Connected to the open end of the connecting pipe 424, the overhead structure 21a4 includes a partition a41, a guide button a42, a tension pad a43, and a belt connection button a44, and the belt connection button a44 is equidistantly distributed with partitions on the circumscribed circle a41 and tension pad a43, the partition a41 is internally welded with a guide buckle a42, and the tension pad a43 is indirectly fitted on the parallel seat 21a3 and the conversion structure 422, and the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com