Fuse and circuit system

A fuse and melt technology, applied in circuits, electrical components, emergency protection devices, etc., can solve problems such as a large number of arcs and poor safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

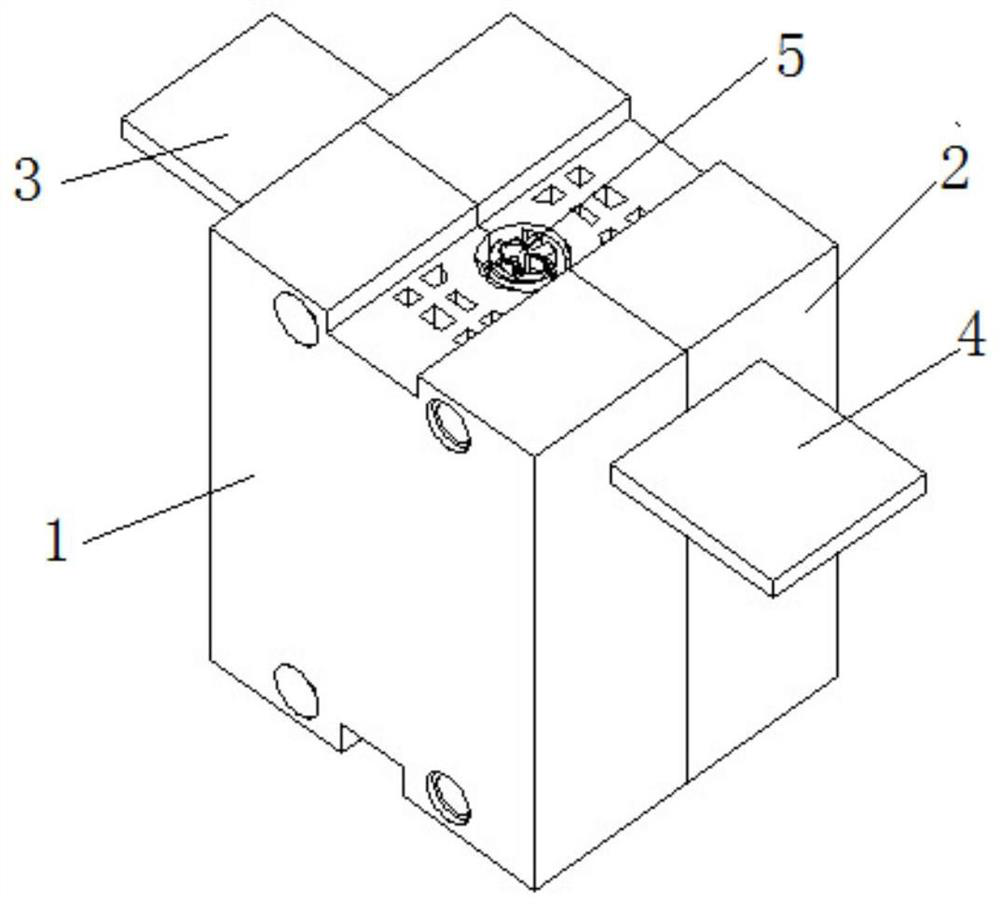

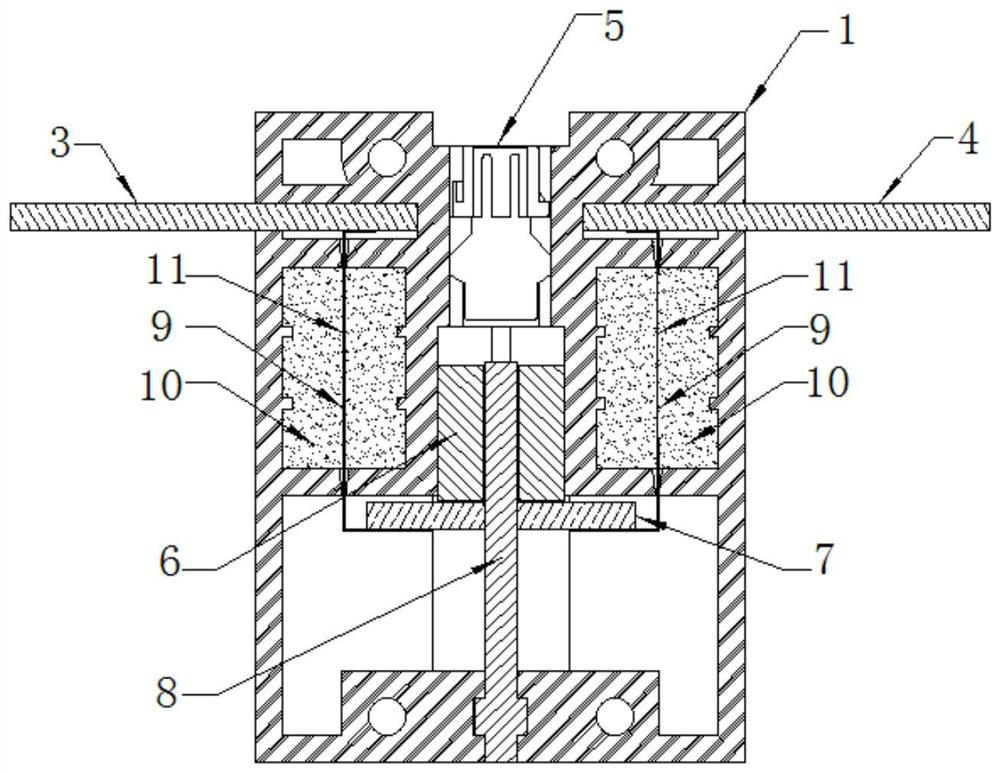

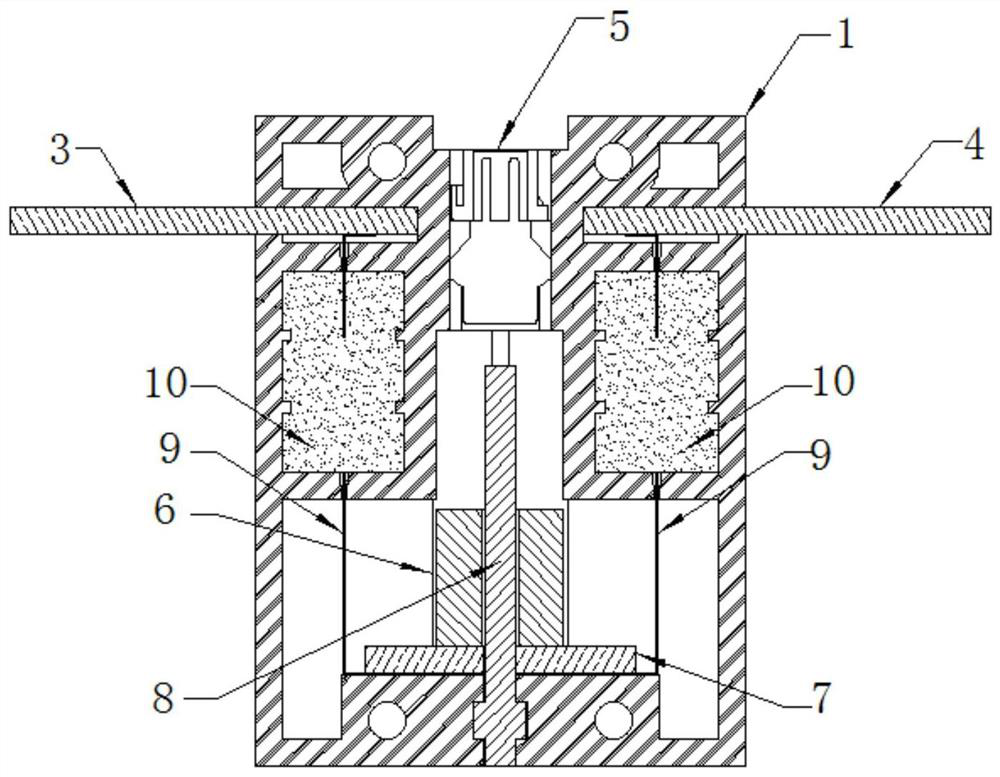

[0069] see figure 1 , figure 2 and image 3 , the housing is composed of the first sub-housing 1 and the second sub-housing 2 arranged on the left and right in an airtight combination. Partial accommodating cavities for accommodating the first conductive terminal 3 and the second conductive terminal 4 are respectively opened on the upper parts of the first sub-housing 1 and the second sub-housing 2 . After the first sub-housing 1 and the second sub-housing 2 are assembled, the first conductive terminal 3 and the second conductive terminal 4 are inserted into the accommodating cavity and are located on opposite sides of the housing at intervals. The combined housing can be fixed by screws.

[0070] A first cavity is opened in the casing between the first conductive terminal 3 and the second conductive terminal 4 , and a second cavity communicating with the first cavity is opened in the casing below the first cavity. The first cavity and the second cavity can be divided int...

Embodiment 2

[0080] see Figure 4 , Figure 5 , Figure 6 and Figure 7 , in this embodiment, the fuse housing is composed of a first sub-housing 21 and a second sub-housing 22 arranged up and down, the first conductive terminal 27 is inserted into the first sub-housing 21 located on the upper part, The two conductive terminals 23 are inserted into the lower second sub-housing 22 . Moreover, the first conductive terminal 27 and the second conductive terminal 23 include opposite parts at intervals, and the disconnection part 232 is disposed on a part of the second conductive terminal 23 opposite to the first conductive terminal 27 . Wherein, the disconnection portion 232 can be obtained by setting a weak point 231 on the second conductive terminal 23, and the weak point 231 can be a perforation or a disconnection groove extending along the width direction of the second conductive terminal 23 at both ends of the disconnection portion 232 and other structures. The shape of the breaking g...

Embodiment 3

[0097] as attached Figure 8As shown, the first conductive terminal 41 and the second conductive terminal 42 are arranged opposite to each other on the left and right sides of the upper part of the housing 43 . The upper part of the housing 43 is provided with two spaced and opposite closed chambers 46 , and the two closed chambers 46 are respectively located at the lower part of the first conductive terminal 41 and the second conductive terminal 42 . The closed chamber 46 on the left side is provided with the first melt 48 disconnected earlier and the first melt 47 disconnected later, and the closed chamber 46 on the right is provided with the first melt 48 disconnected earlier. Two melts and a second melt after disconnection.

[0098] The cavity at the bottom of the housing 43 is provided with a connecting conductive terminal 52, the upper end of the first disconnected first melt 48 and the later disconnected first melt 47 are connected to the first conductive terminal 41, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com