A cabinet-type server indirect cold plate type liquid-cooled anti-leakage system and control method

A server and cabinet-type technology, which is applied in the cabinet-type server indirect cold plate type liquid cooling leak-proof system and control field, can solve the problems of hidden dangers of coolant leakage, improve operation reliability, reduce the risk of liquid leakage, and prevent coolant leakage. The effect of the leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

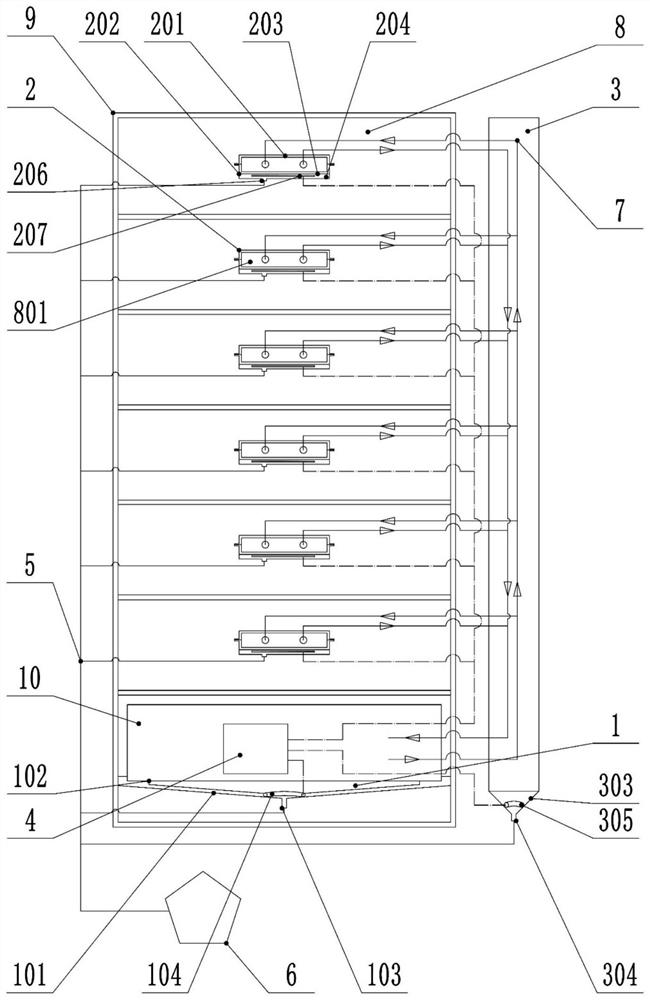

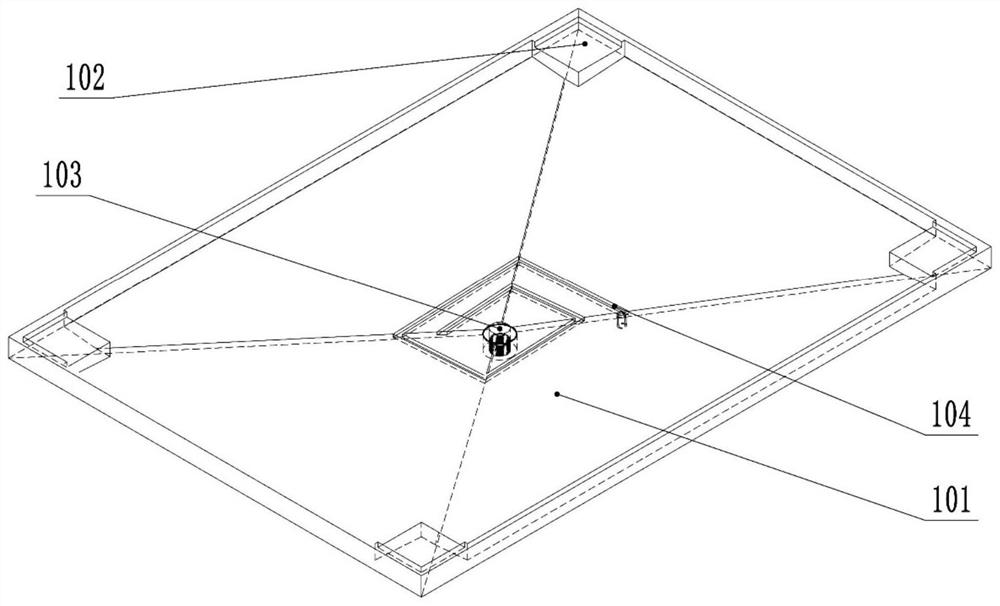

[0034] see figure 1 , an indirect cold plate liquid cooling leakage prevention system for a cabinet server, comprising a liquid cooling circulation module 10, a liquid cooling pipeline 7, a liquid cooling server 8, a leakage prevention tray unit 1, an indirect cold plate liquid cooling element leakage prevention unit 2, Liquid cooling pipeline leakage prevention unit 3 , control unit 4 , drainage pipeline 5 and leakage liquid collection unit 6 .

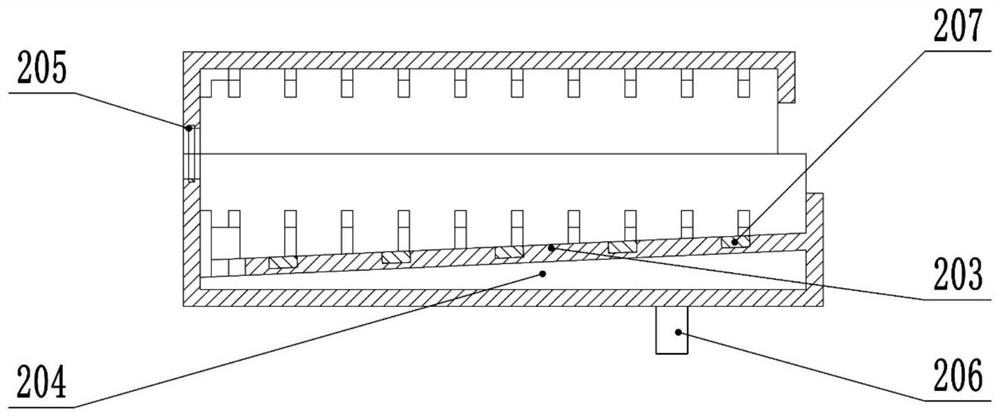

[0035] The liquid cooling server 8 is provided with an indirect cold plate type liquid cooling element 801. The indirect cold plate type liquid cooling element 801 includes a heat conduction plate 8011, a heat pipe 8012, and a heat exchange module 8013. The heat generated by the chips in the liquid cooling server 8 is passed through the heat conduction plate 8011. The heat is introduced into the heat pipe 8012, and then the heat is conducted by the heat pipe 8012 to the heat exchange module 8013 and taken away by the cooling liquid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com