Cryogenic austenitic high-manganese steel having excellent corrosion resistance, and manufacturing method therefor

A corrosion-resistant, austenitic technology, applied in austenitic high-manganese steel and its manufacturing field, can solve the problems of inapplicability, economic efficiency and difficult low-temperature physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

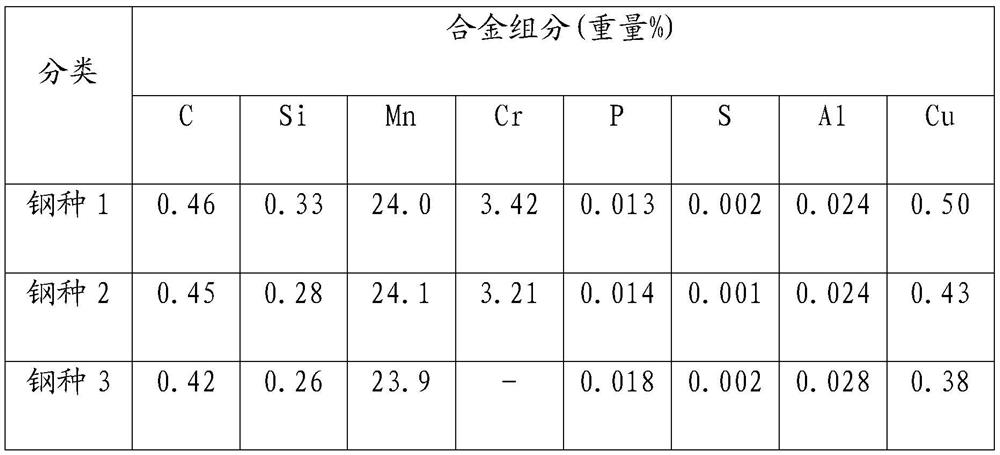

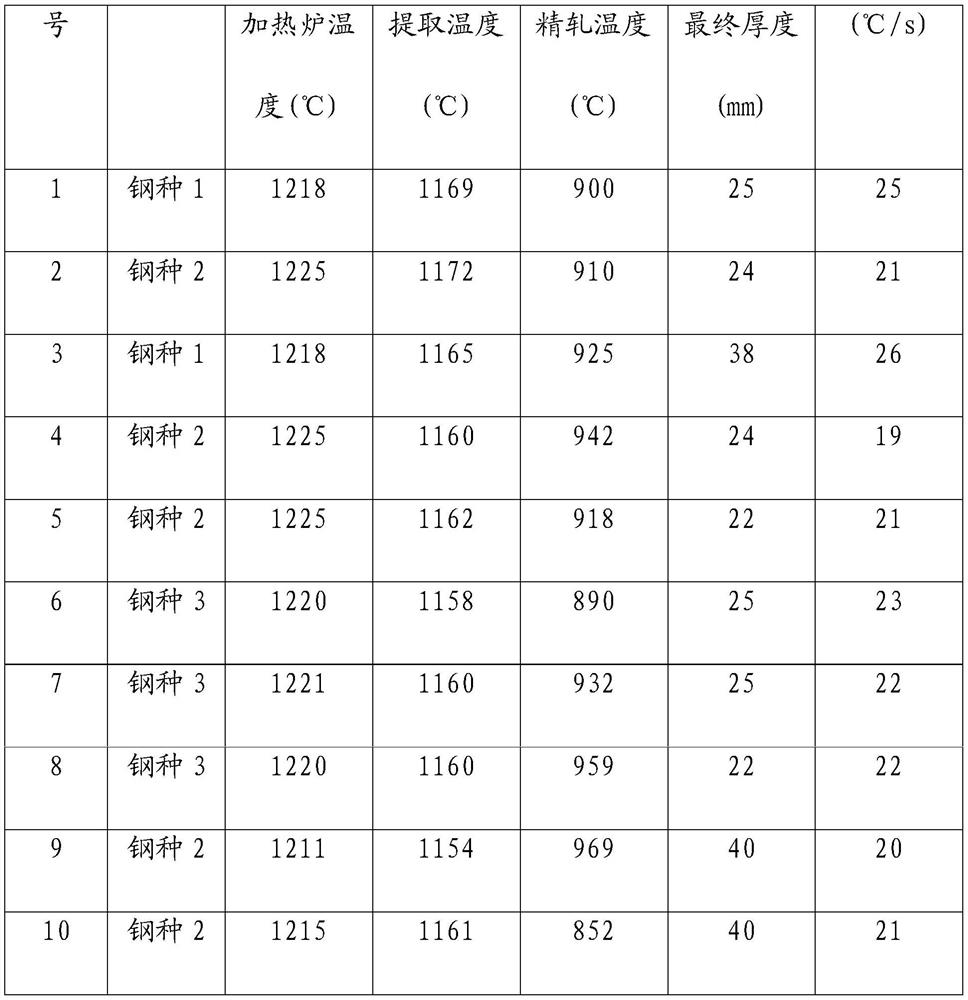

[0022] The present invention relates to an austenitic high-manganese steel material for ultra-low temperature with excellent corrosion resistance and a manufacturing method thereof. Preferred embodiments of the present invention are described below. The present invention can be modified and implemented in various ways, and the scope of the present invention should not be construed as being limited to the following examples. Embodiments of the present invention are provided below to enable those skilled in the art to which the present invention pertains to understand the present invention in more detail.

[0023] Hereinafter, the steel composition of the present invention will be described in more detail. Unless otherwise specified, the percentages representing the content of each element are based on weight.

[0024] According to one aspect of the present invention, the austenitic high-manganese steel material for ultra-low temperature with excellent corrosion resistance may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com