Filter screen flushing device of filter press

A technology of flushing device and filter press, which is applied in the direction of filtration separation, filter regeneration, separation method, etc., and can solve the problem of huge consumption of water resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is further described in detail through specific implementation methods:

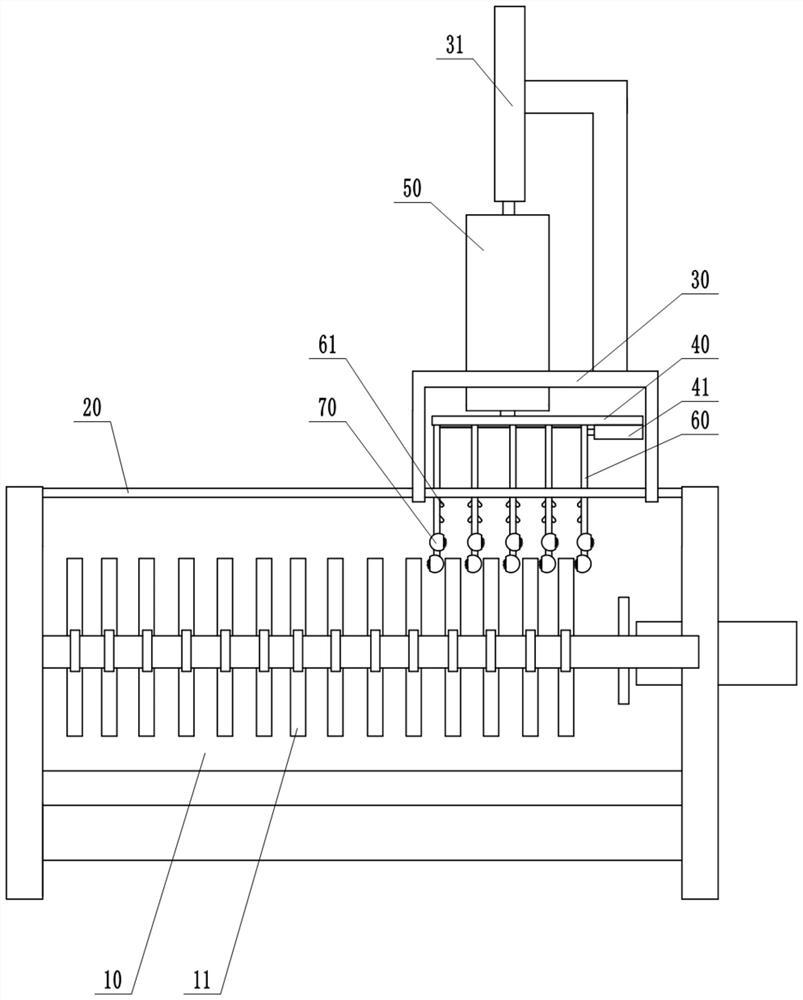

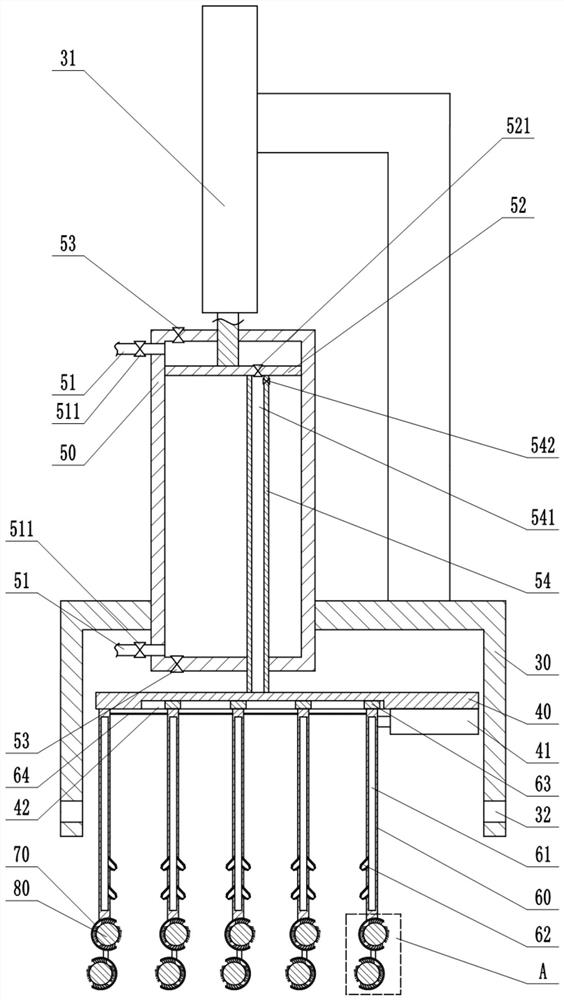

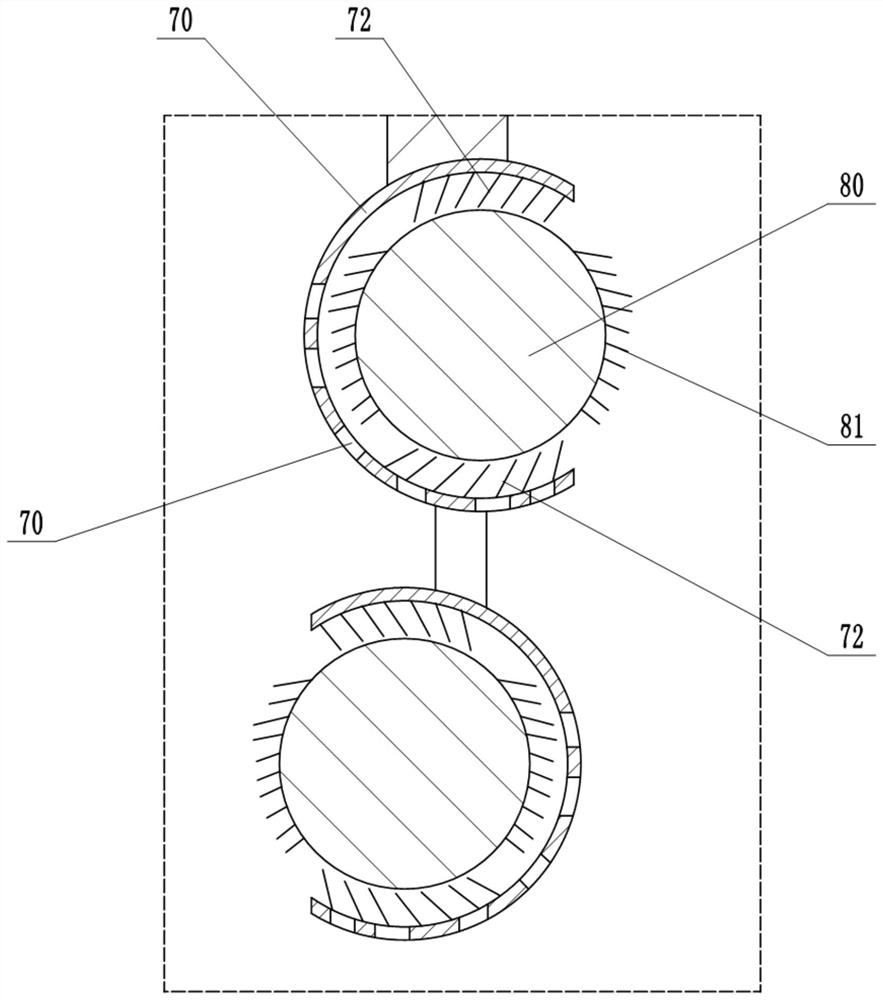

[0022] The reference signs in the accompanying drawings of the description include: filter press 10, filter frame 11, sliding track 20, sliding seat 30, power part 31, through hole 32, mounting seat 40, driving part 41, chute 42, piston cylinder 50 , water inlet pipe 51, one-way water inlet valve 511, piston 52, second one-way drain valve 521, solenoid valve 53, connecting rod 54, cavity 541, first one-way drain valve 542, flow channel 61, installation rod 60 , Nozzle 62, slide block 63, connecting rope 64, shell 70, port 71, cleaning tooth 72, rotating roller 80, bristle 81.

[0023] This embodiment is basically as figure 1 , figure 2 As shown: the filter screen flushing device of the filter press, including a cleaning mechanism and sliding rails 20 for the cleaning mechanism to slide, two sliding rails 20 are provided, and the two sliding rails 20 are respectively welded on oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com