Fully-closed production type green mine

A fully enclosed and green technology, applied in the direction of cleaning method, separation method, cleaning method and utensils using gas flow, it can solve the problems such as easy to generate dust, environmental pollution, and can not meet the concept of green mining, so as to reduce dust phenomenon, improve environmental quality, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

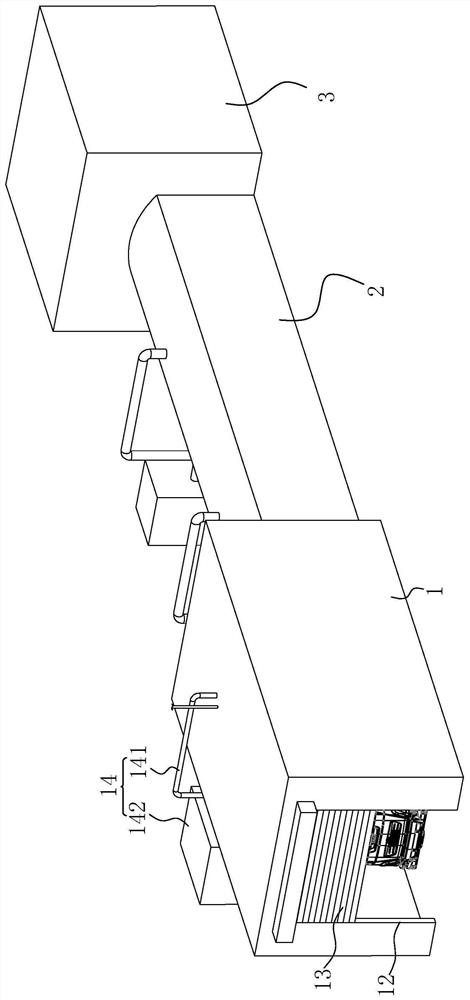

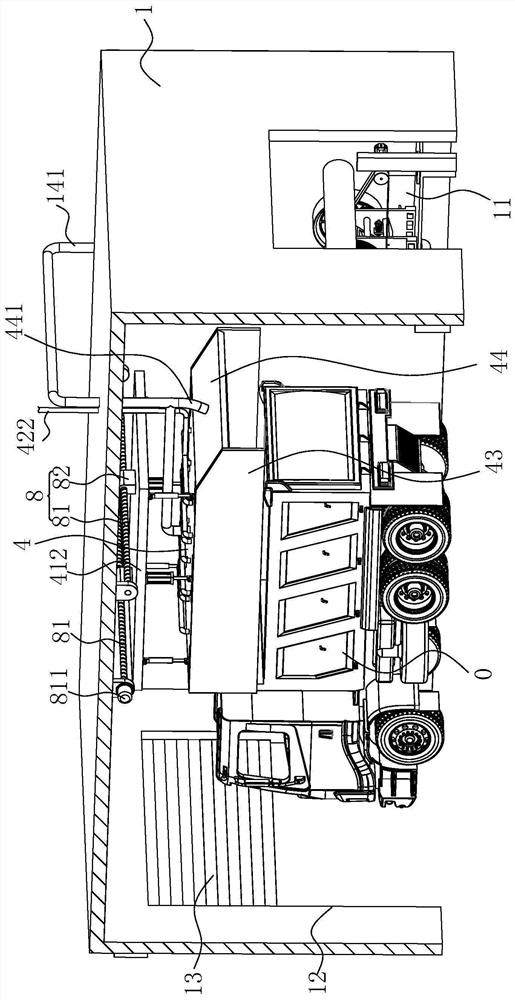

[0040] The following is attached Figure 1-5 The application is described in further detail.

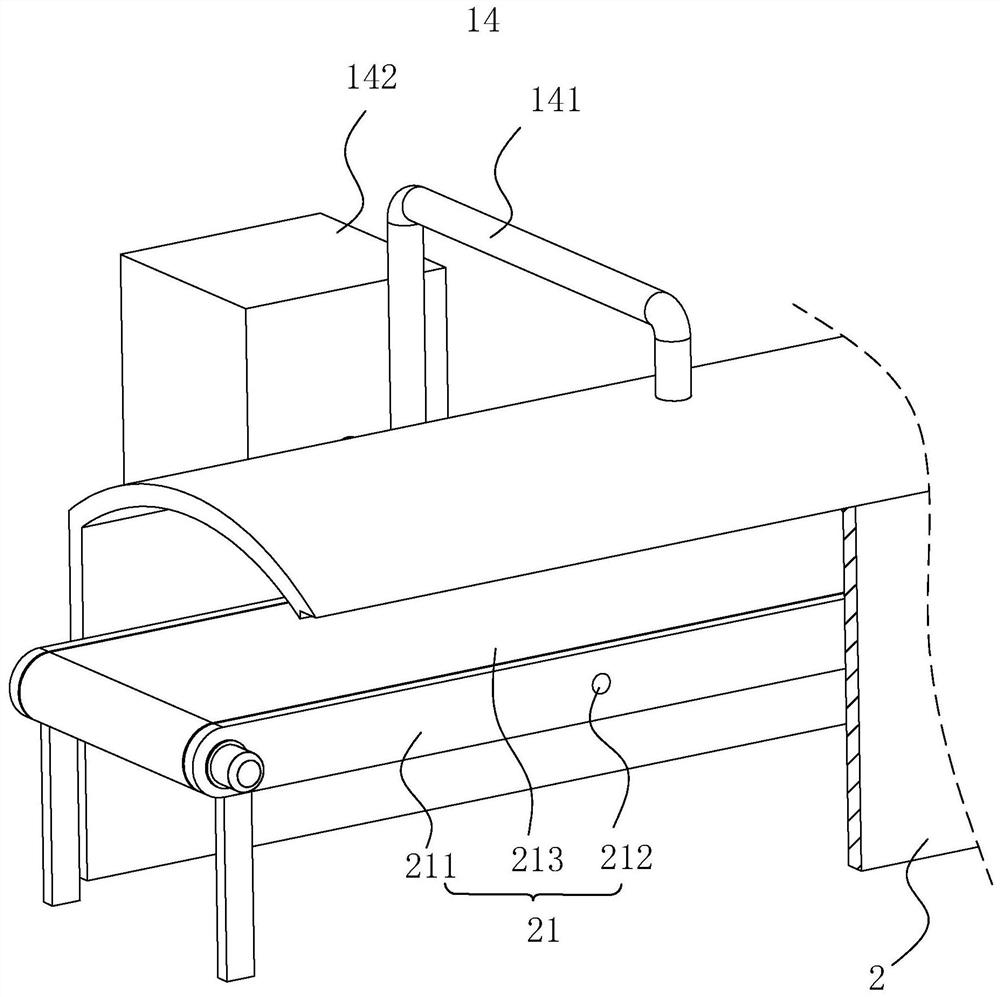

[0041] The embodiment of the present application discloses a fully enclosed green mine. combine figure 1 and figure 2 , a fully enclosed green mine includes a crushing chamber 1, a crusher 11 is arranged in the crushing chamber 1, a conveying bin 2 is connected to one side of the crushing chamber 1 in the length direction, and a conveying device 21 for conveying ore is arranged in the conveying chamber 2 (refer to image 3 ), the side of the conveying bin 2 away from the crushing chamber 1 is connected with the stacking chamber 3; the side of the crushing chamber 1 far away from the conveying bin 2 is provided with a vehicle entrance 12, and a shelter door 13 is provided at the entrance 12. During the crushing production, after the mine car enters the crushing chamber 1 through the car entrance 12, the shielding door 13 is closed, and then the ore is poured into the crushing cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com