Manufacturing technology of internal and external splines of gear hubs of automatic gearbox clutch

A technology of automatic gearbox and preparation process, which is applied in the field of internal and external spline processing, which can solve the problems of high equipment tonnage requirements, short service life, and large one-time investment, so as to improve the preparation efficiency, ensure the roundness, and reduce the processing procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make it easier for those skilled in the art to understand the present invention, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings.

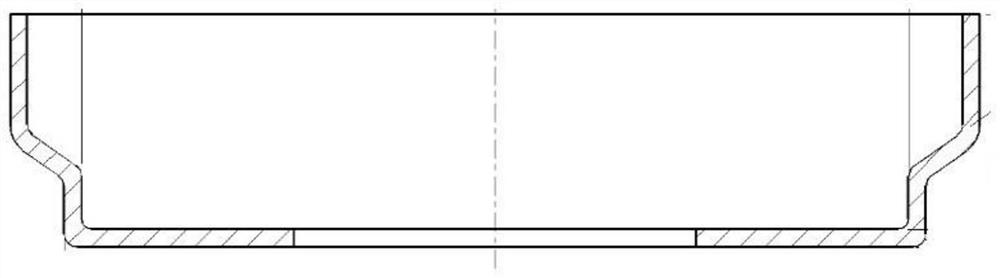

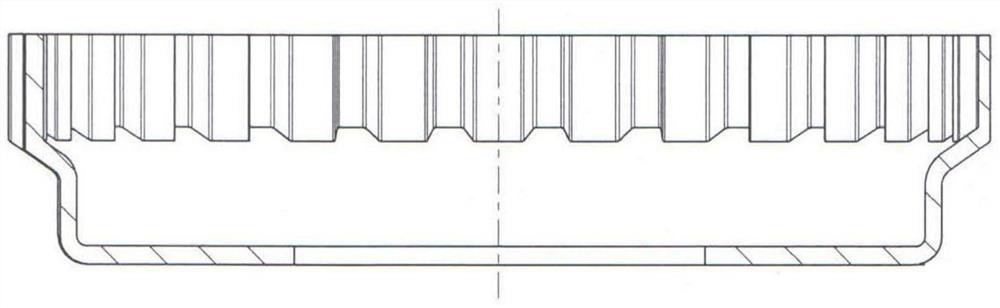

[0024] Such as Figure 1-8 As shown, the present invention provides a process for preparing the internal and external splines of the clutch gear hub of an automatic transmission, which includes the following steps: in the first step, the external mechanical arm places the sheet material on the leveling machine, and the sheet material is leveled by the leveling machine , and ensure that the plane difference of the entire sheet metal needs to be less than 0.2mm to ensure the consistency of the wall thickness of the clutch hub; in the second step, the external mechanical arm places the sheet metal processed by the leveling machine in the positioning punching die, and the sheet metal The material is stamped into a round sheet blank, such as figure 1 ; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com