Thread rolling machine capable of machining thread ends with different lengths and machining method

A threaded end and thread rolling machine technology, which is applied in the field of thread rolling machines, can solve the problems of troublesome adjustment of threaded end length, rigid feeding method, troublesome material collection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

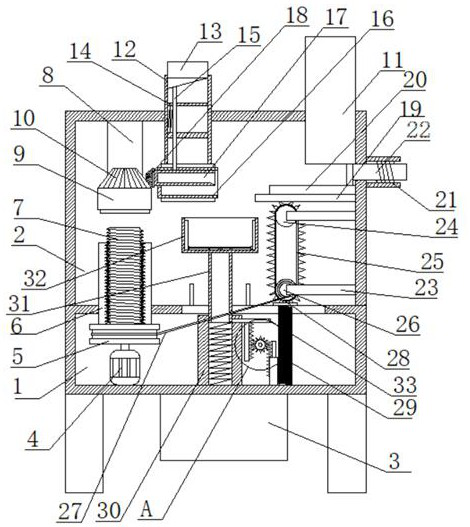

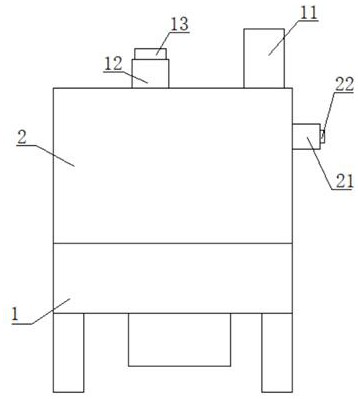

[0033] refer to Figure 1-7In this embodiment, a tooth rolling machine capable of processing threaded ends of different lengths is proposed, including a base 1, and the base 1 is a hollow structure, the top of the base 1 is fixedly installed with a casing 2, and the bottom of the base 1 is fixedly connected with a storage box 3. A motor 4 is fixedly installed inside the bottom of the base 1, and one end of the output shaft of the motor 4 is fixedly connected to a winding disc 5, and the top of the winding disc 5 is fixedly connected to an extension tube 6, and the top of the extension tube 6 extends into the casing 2, The extension pipe 6 is internally threaded to a No. 1 threaded post 7, and the extension pipe 6 can drive the No. 1 threaded post 7 to rise and fall. The top of the shell 2 is fixedly connected with a fixed ring 8, and the fixed ring 8 is rotatably connected with a hollow ring 9 , the fixed ring 8 plays the role of stabilizing the hollow ring 9, and the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com