A connecting sheet ultrasonic welding machine

A technology of ultrasonic welding and connecting piece, which is applied in the direction of welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve the problems of low welding processing efficiency of connecting piece and tab, and achieve the purpose of overcoming spatter and oxidation and solving the problem of processing Difficulty, the effect of preventing bursting of welding marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] In the process of battery product processing, it is necessary to clamp the connecting piece on the tab and complete the welding. The connecting piece is made by superimposing two pieces of objects. Before welding, it needs to be separated before it can be clamped to the tab. On the one hand, because the processing difficulty is relatively high, the traditional processing efficiency is relatively low and needs to be improved urgently; in order to solve the above-mentioned technical problems, the present embodiment provides the following technical solutions:

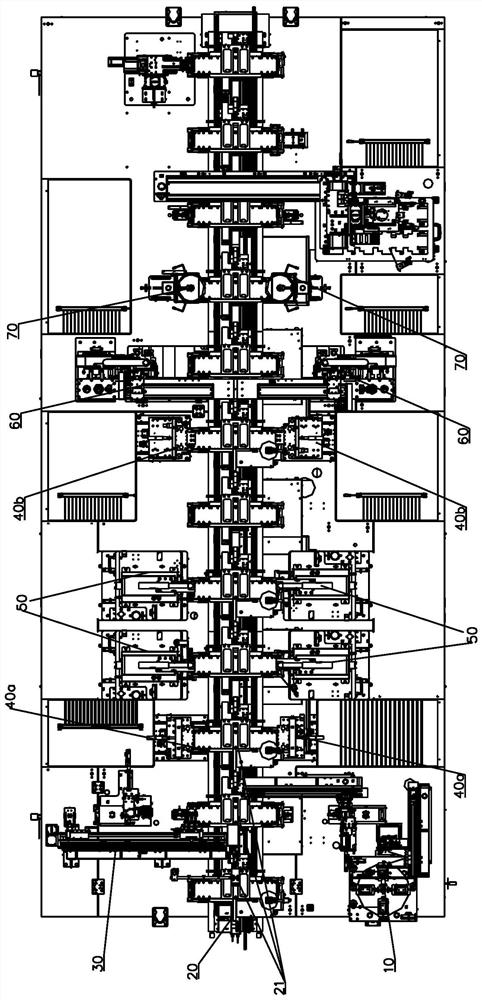

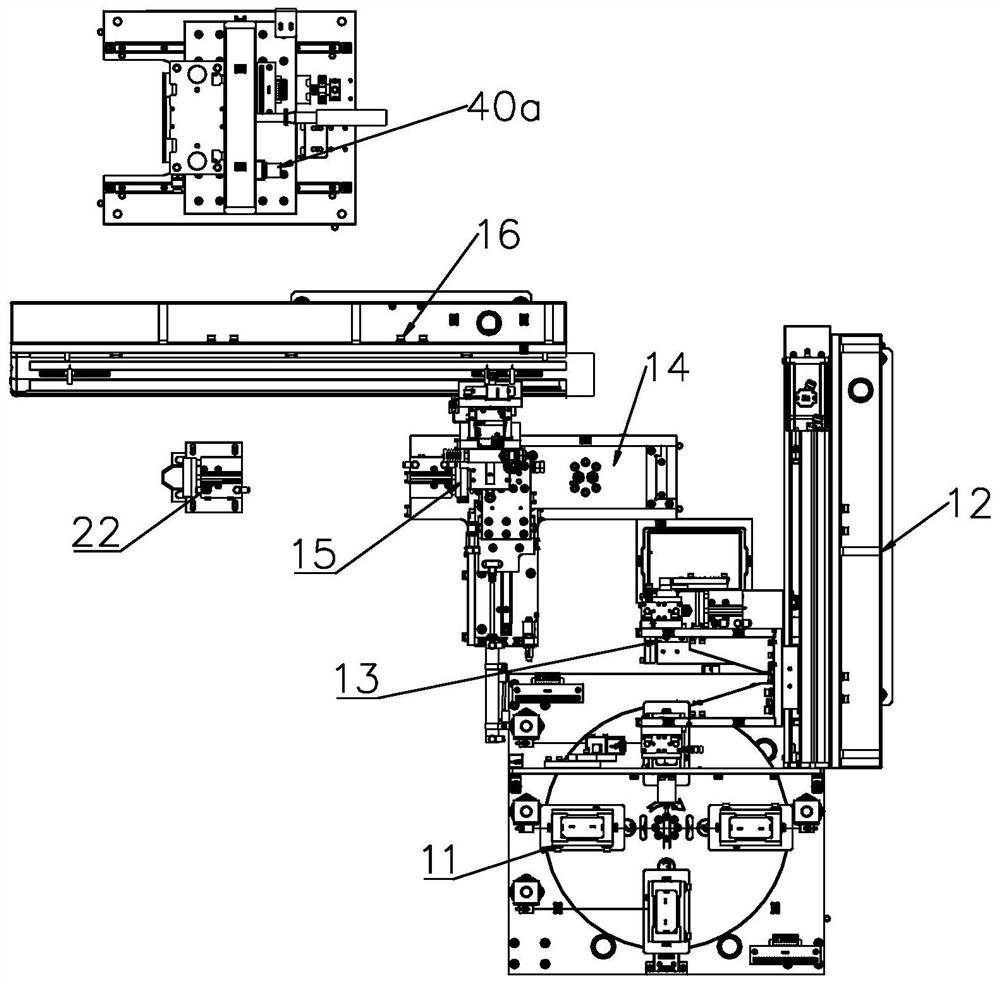

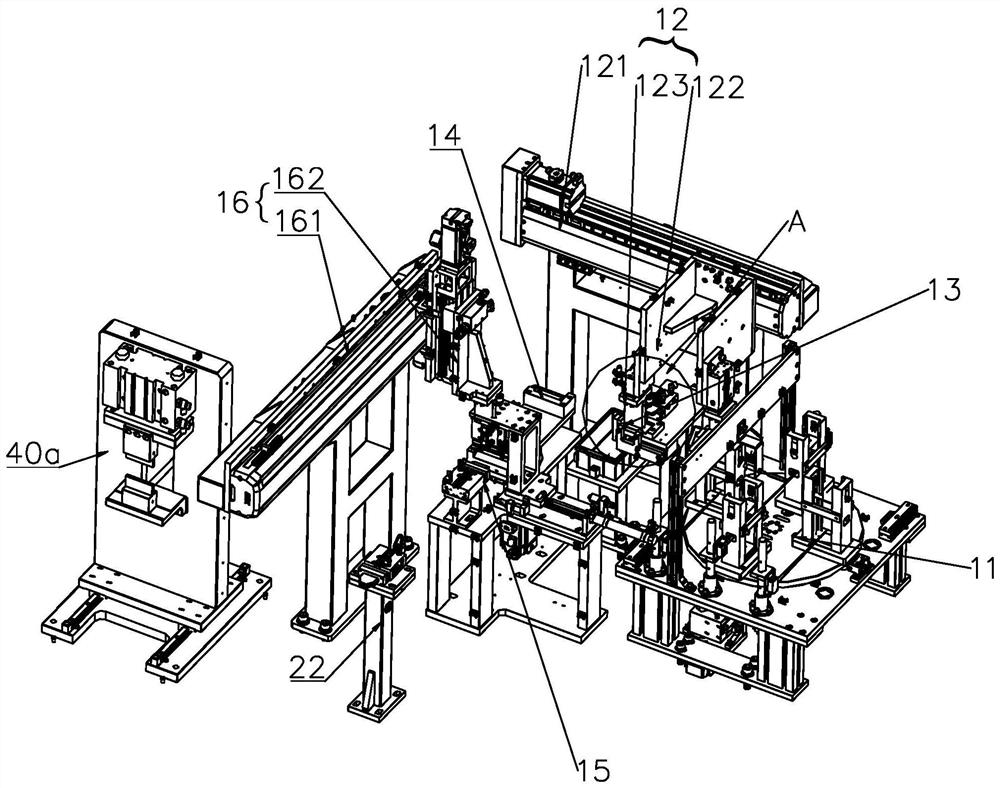

[0062] Specifically, see Figure 1-15 , this embodiment provides a connecting piece ultrasonic welding machine for welding the connecting piece and the pole lug, wherein the connecting piece is formed by stacking two layers, and the ultrasonic welding machine provided by this application divides the connecting piece and attaches it to the pole on both sides of the ear, and fix them by welding;

[0063] Specifically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com