Polishing device with good buffering performance for hardware tool

A hardware tool and buffering technology, applied in the field of polishing equipment for hardware tools, can solve the problems of unusable, different, excessive wear of sandpaper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

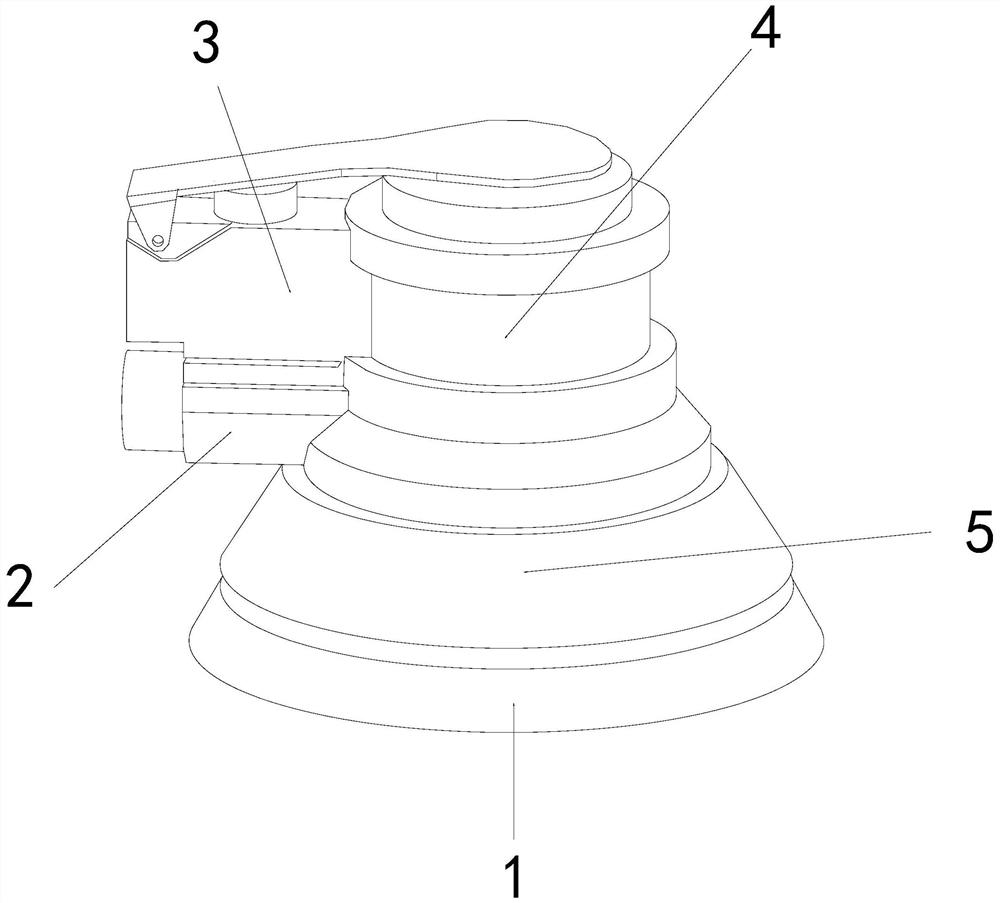

[0027] as attached figure 1 to attach Figure 5 As shown, the present invention provides a kind of polishing equipment for hardware tools with good cushioning performance. Its structure includes a polishing mechanism 1, a connector 2, a grip bar 3, a rotator 4, and a connector 5. The upper end of the polishing mechanism 1 is movable. Closed to the lower end of the connector 5, the right side of the connector 2 is welded and connected to the left side of the rotator 4, the right end of the holding rod 3 is embedded and fixed on the left outer wall of the rotator 4, and the lower end of the rotator 4 is embedded and connected on the upper end of the connector 5;

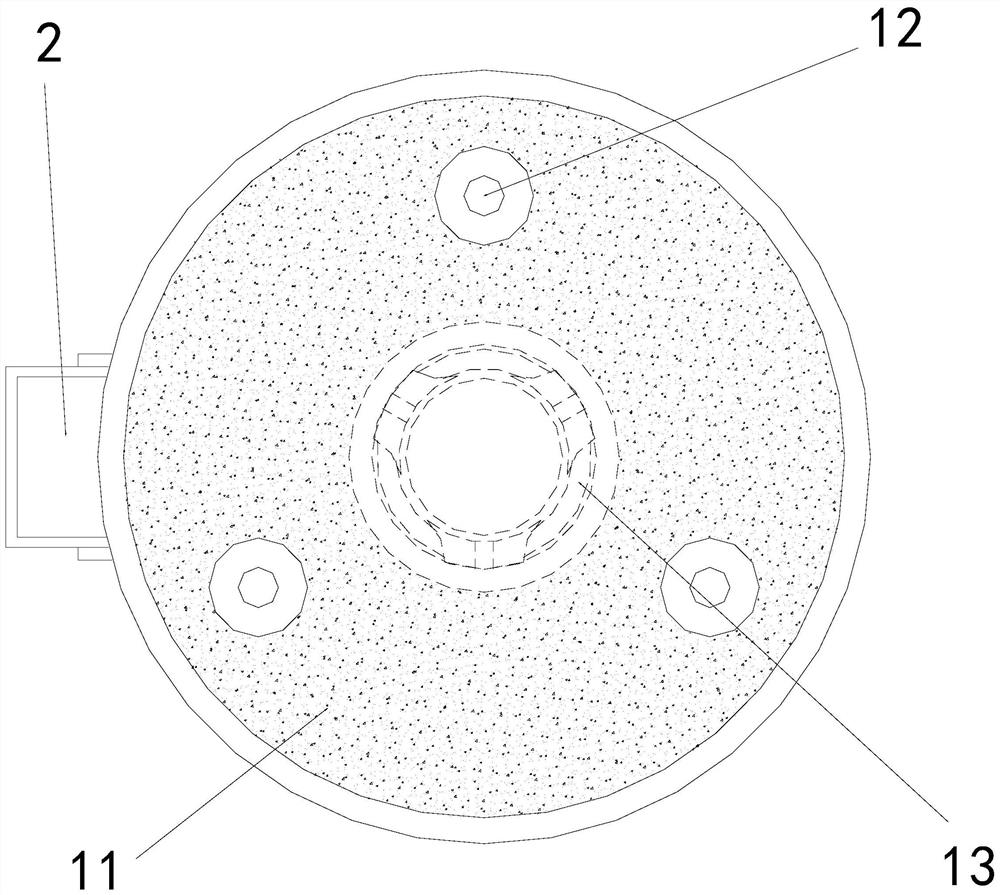

[0028] The polishing mechanism 1 is composed of a grinding disc 11, a fixed buckle 12, and a rotator 13. One end of the grinding disc 11 is embedded and fixed at the lower end of the connector 5, and the fixed buckle 12 is movably engaged on the surface of the grinding disc 11. The outer wall of the rotator 13 is emb...

Embodiment 2

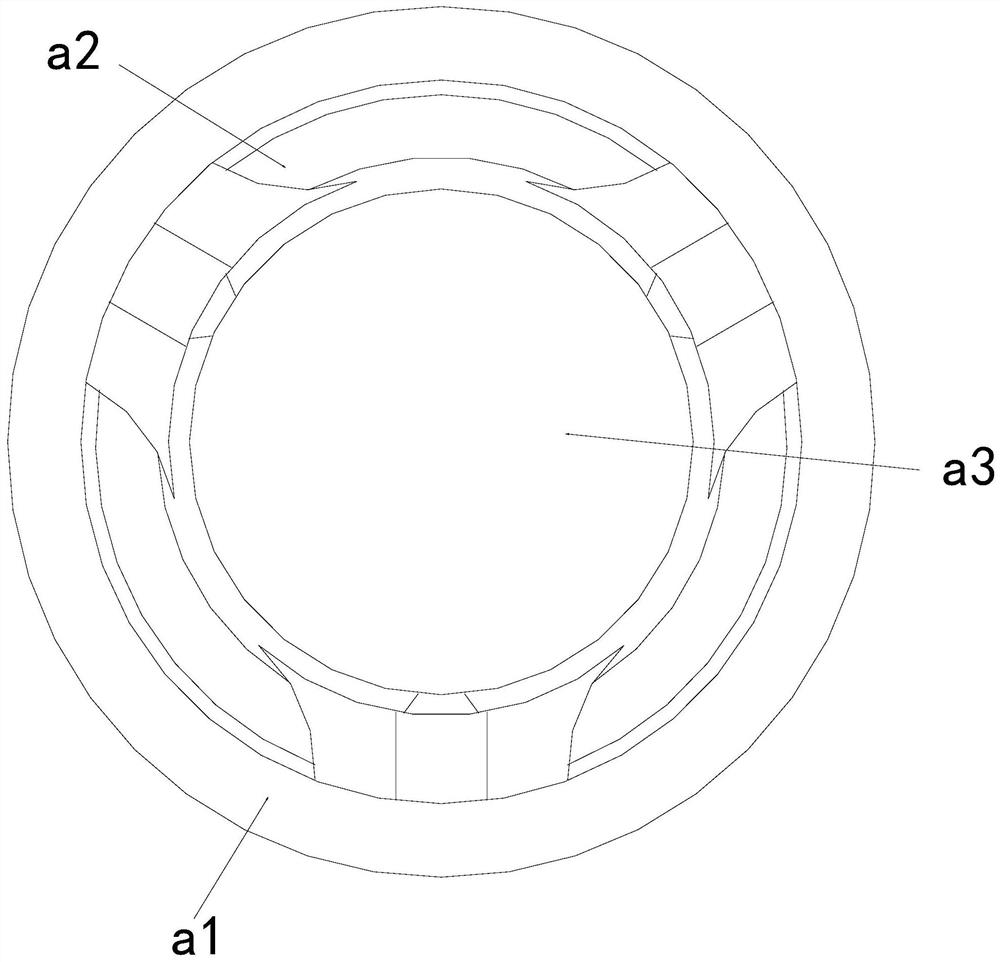

[0034] as attached Image 6 to attach Figure 8 As shown: the reciprocator b3 is composed of a resetter d1, an assembly box d2, a limit ring plate d3, a rotating rod d4, and a positioning ring d5, and the inner wall of the resetter d1 is fixed on the outer wall of the middle section of the rotating rod d4 with interference. One end of the assembly box d2 is movably fitted to both ends of the reset device d1, the outer wall of the limiting ring d3 is movably fitted to the inner wall of the assembling box d2, and the two ends of the rotating rod d4 are welded and connected between the limiting ring d3 , the inner wall of the positioning ring d5 is clearance fit with the outer wall of one end of the rotating rod d4, and there are two limiting ring plates d3 arranged in parallel at both ends of the rotating rod d4, and the limiting ring plates d3 provided at both ends will be So that the position of the rotating rod d4 is limited parallel.

[0035] Wherein, the reset device d1 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap