Electromagnetic attraction equipment

An adsorption equipment and electromagnetic technology, applied in the direction of conveyor objects, load hanging components, hoisting devices, etc., can solve problems such as fracture and deformation of steel cages, and achieve the effect of avoiding deformation and fracture and improving recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] At present, shrinkage cavities often occur during pile foundation construction in unfavorable geological areas such as silt, and it is necessary to take out the reinforcement cage from the pile hole and recycle it.

[0025] For ease of description, take the extraction of reinforcement cage 40 as an example below for illustration

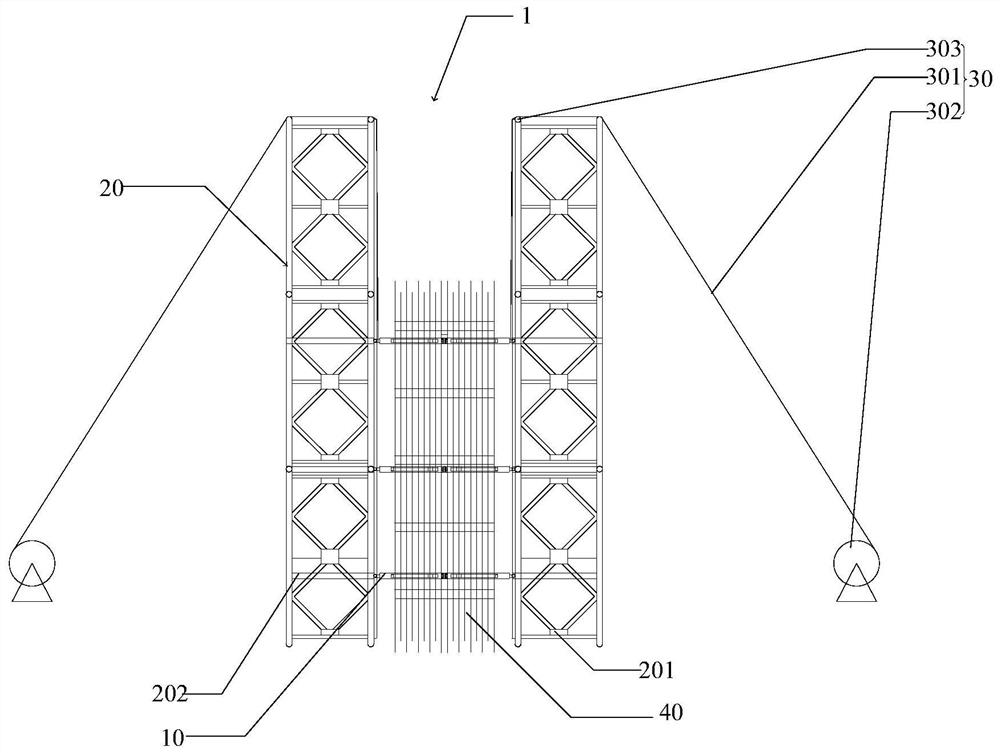

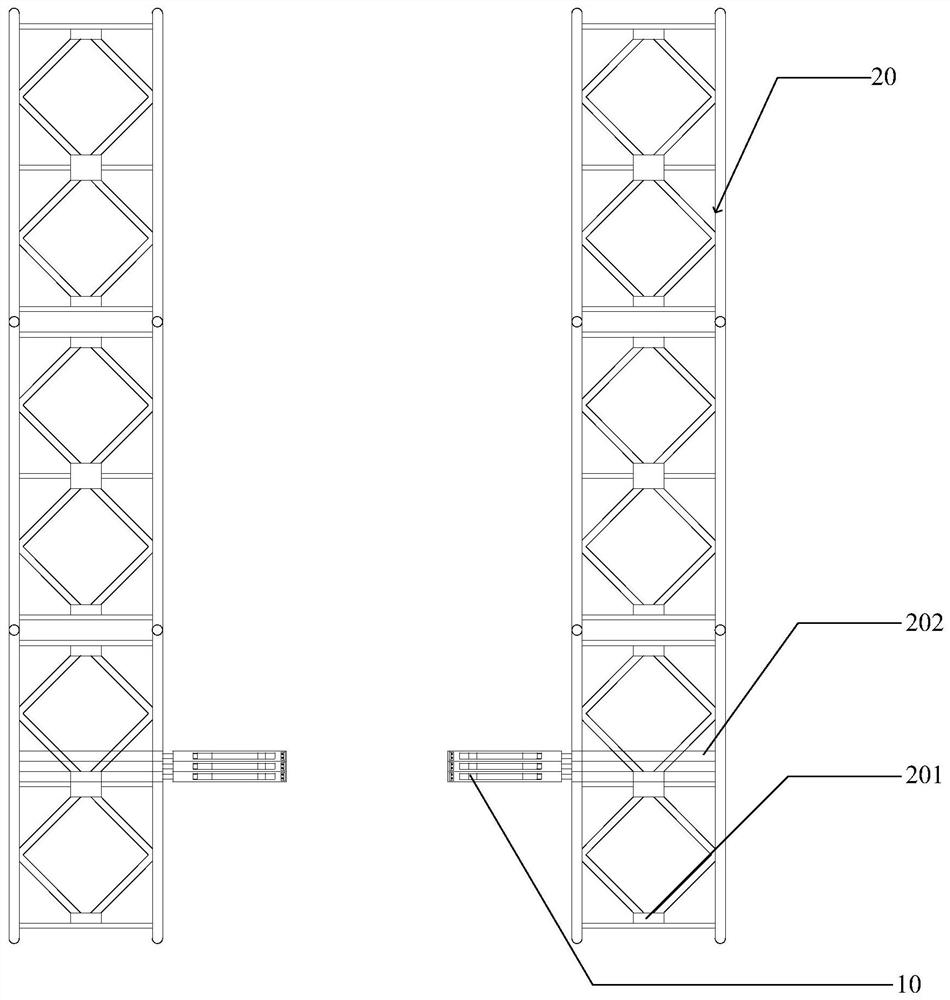

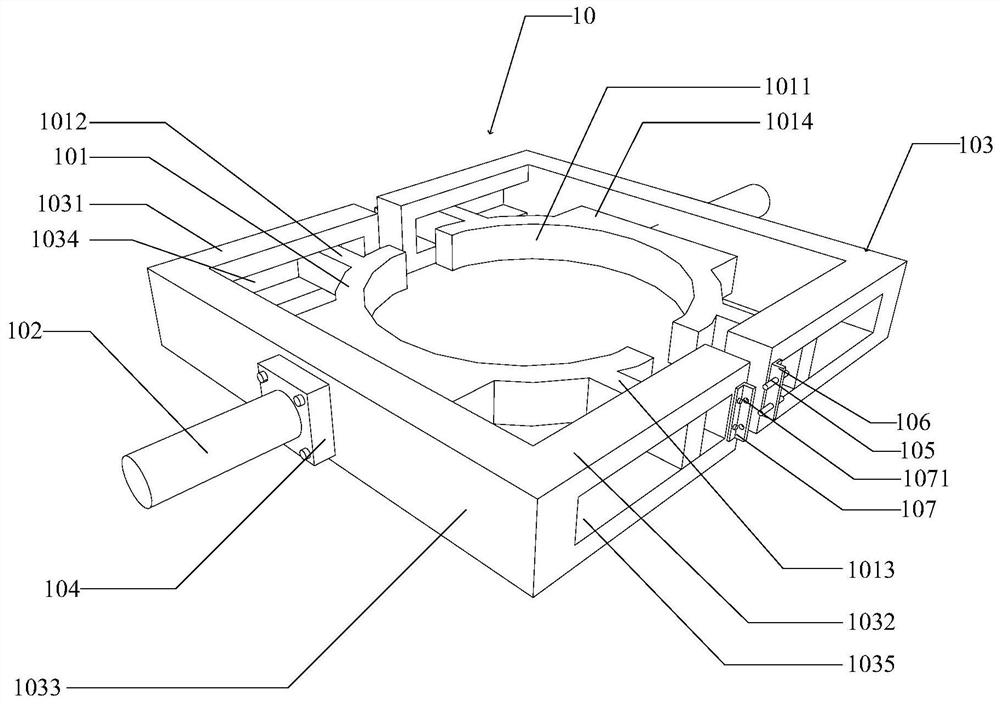

[0026] refer to Figure 1 to Figure 4 , is an electromagnetic adsorption device 1 disclosed in the present invention, comprising an electromagnetic adsorption assembly 10 and a driving device 30, the electromagnetic adsorption assembly 10 is connected to a steel cage 40, the electromagnetic adsorption assembly 10 includes an electromagnetic chuck, and the outer wall of the electromagnetic chuck is provided There is a connecting piece 102, the electromagnetic chuck is connected with the steel cage 40, and the connecting piece...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap