High-perpendicularity electric pole and construction technology thereof

A verticality, pole technology, applied in infrastructure engineering, building types, buildings, etc., can solve problems such as safety accidents of poles, and achieve the effect of improving service life, reducing inclination, and reducing inclination of linear poles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

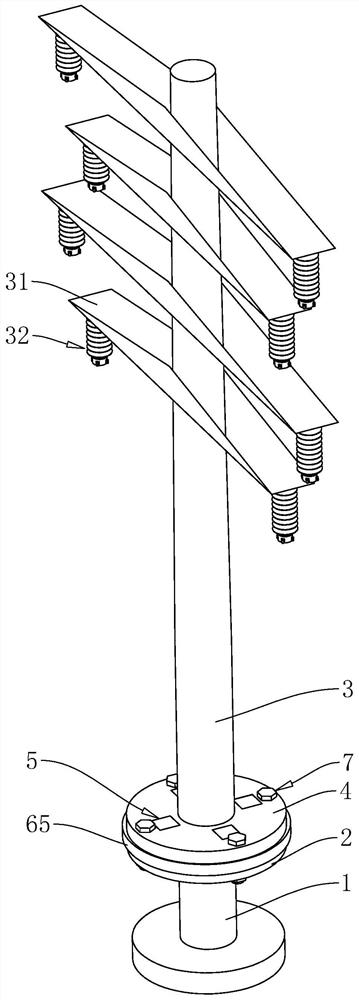

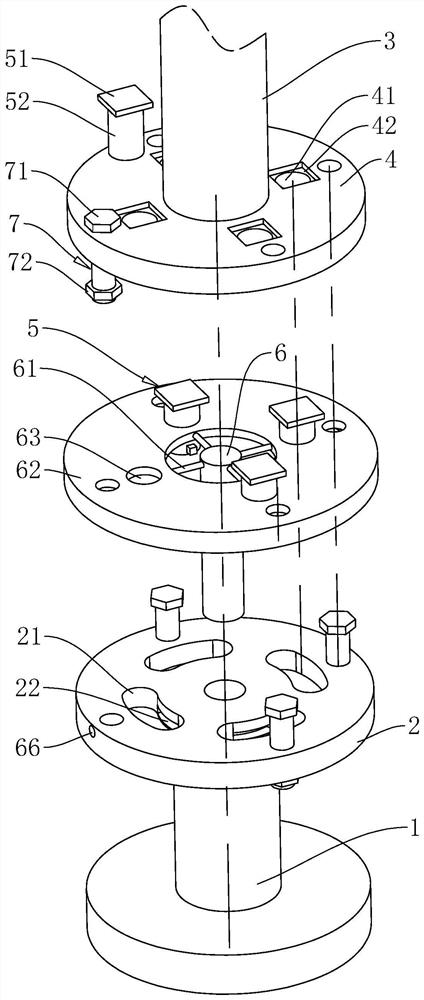

[0038] The following is attached Figure 1-4 The application is described in further detail.

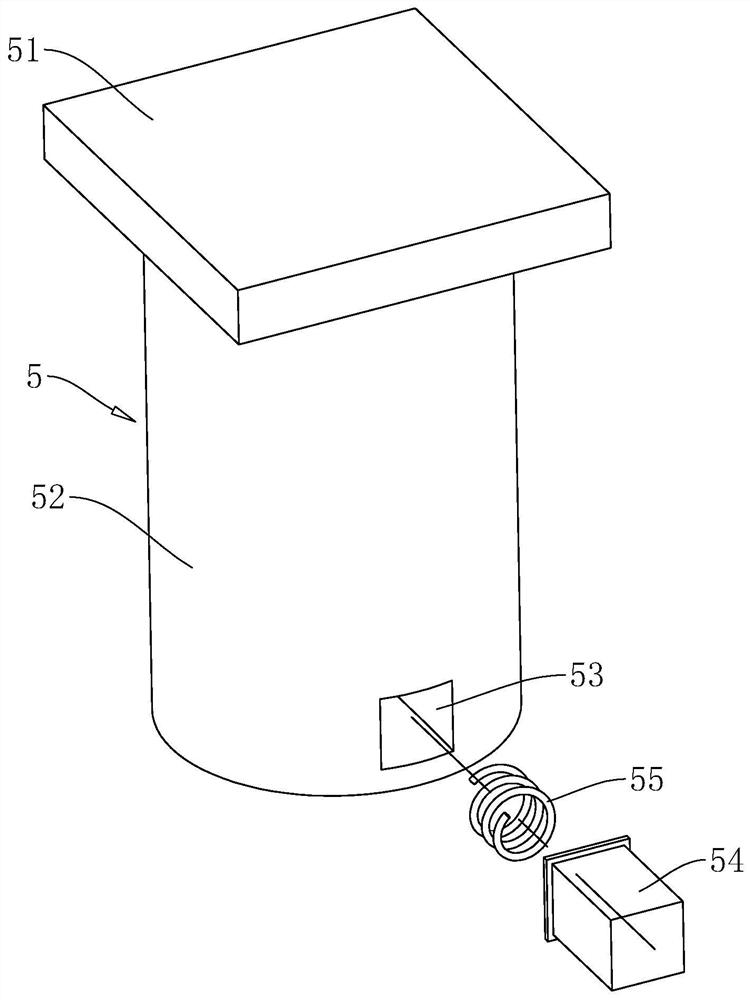

[0039] The embodiment of the present application discloses a pole with high verticality. refer to figure 1 A pole with high verticality includes a pre-embedded base 1, a first deck 2, a second deck 4 and a linear rod 3 arranged in sequence from bottom to top, the pre-embedded base 1, the first deck 2 and the second Card holder 4 is buried in the ground, and one section of linear rod 3 is buried in the ground, and another section stands vertically on the ground. The first deck 2 is welded to the pre-embedded base 1 , and the first deck 2 and the pre-embedded base 1 are arranged coaxially. The first deck 2 and the second deck 4 are connected and fixed, and the first deck 2 and the second deck 4 may be connected by means of bolts 7 . Both the diameters of the first deck 2 and the second deck 4 are larger than the diameter of the linear rod 3 , and the first deck 2 and the second dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com