Intelligent oxygen supply system for tunnel face in plateau area

An oxygen supply system and tunnel surface technology, which is applied in mine/tunnel ventilation, safety devices, mining equipment, etc., can solve problems such as inability to display oxygen content data on LED screens, lack of user terminals, and insufficient oxygen utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

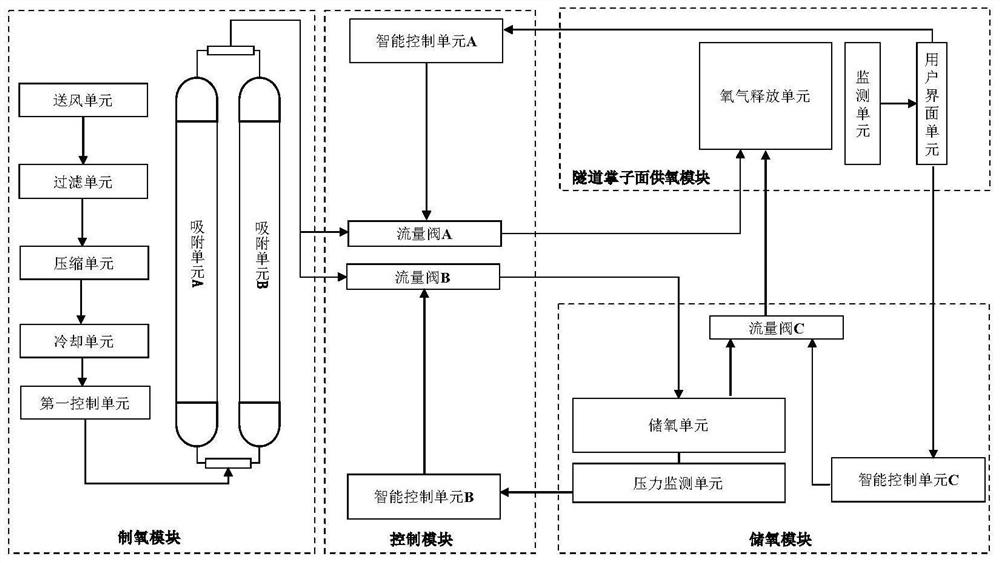

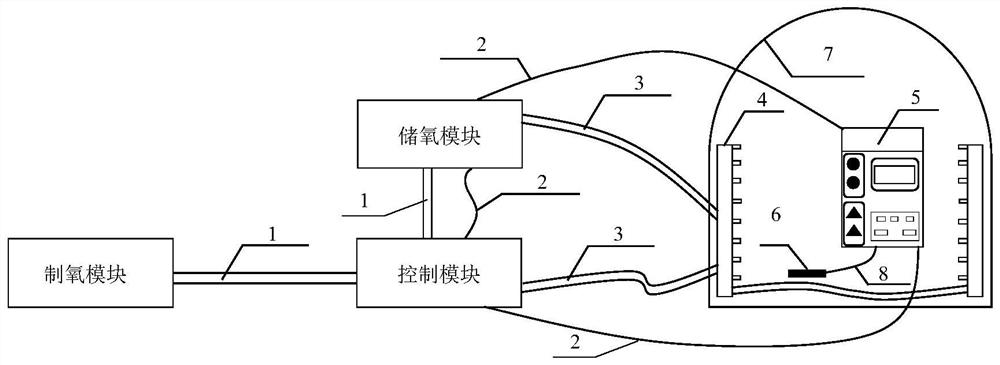

[0045] An intelligent diffuse oxygen supply system for the face of a plateau tunnel, including an oxygen generation module, a control module, a storage module, and an oxygen supply module for the face of the tunnel;

[0046] The oxygen generation module is connected to the control module through the oxygen delivery pipe 1, and the control module and the oxygen storage module are connected through the oxygen delivery pipe 1;

[0047] The pressure sensor inside the oxygen storage module is connected to the intelligent control unit B inside the control module through the RS232 connection line 2, and the oxygen flow through the flow valve B is controlled by the intelligent control unit B;

[0048] The control module and the storage module deliver oxygen to the oxygen distribution panel 4 through the oxygen delivery hose 3, and release oxygen to the tunnel face 7 through the oxygen distribution panel 4;

[0049] The tunnel face 7 is equipped with an oxygen monitor 6, and the data m...

Embodiment 2

[0052] The oxygen storage module of this embodiment is installed near the face 7 of the tunnel, and is used to purify the oxygen in the air, and is connected to the flow valve A and the flow valve B of the control module through the oxygen delivery pipe 1, and the flow valve A and the flow valve B are respectively The oxygen distribution panel 4 and the oxygen storage unit of the oxygen storage module are connected through the oxygen delivery pipe 1 and the oxygen hose 3;

[0053] In this embodiment, the internal pressure monitoring unit of the oxygen storage module can monitor the oxygen pressure inside the oxygen storage unit in real time, and connect to the intelligent control unit B in the control module through the RS232 connection line. When the oxygen pressure is close to the limit storage capacity of the oxygen storage unit When the oxygen pressure is high, the intelligent control unit B intelligently adjusts the opening of the flow valve B, thereby controlling the amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com