Pilot middle cavity balance pressure-type ultrahigh pressure ball valve for oil and gas production equipment

A technology for oil and gas extraction and ultra-high pressure, applied in mechanical equipment, valve devices, cocks including cut-off devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

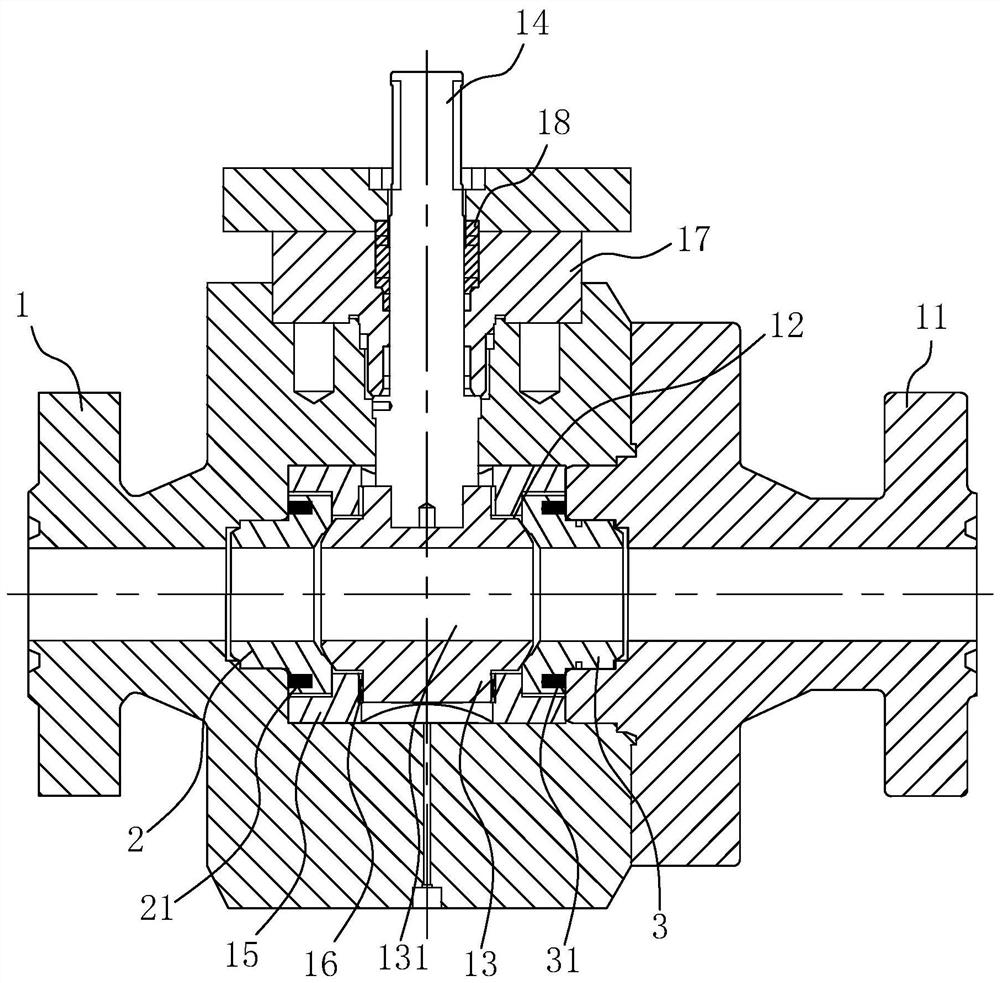

[0039] A kind of oil and gas production equipment with a pilot cavity balance pressure type ultra-high pressure ball valve, such as Figure 1 to Figure 3 As shown, it includes: a main valve body 1, an auxiliary valve body 11 is provided on one side of the main valve body 1, an installation chamber 12 is provided in the main valve body 1, and a valve ball 13 is rotatably connected to the installation chamber 12, and the valve ball The middle part of 13 is provided with a diversion channel 131, and the main valve body 1 is rotatably connected with a valve stem 14 fixed to the valve ball 13; and the second sealing valve seat 3, the first sealing valve seat 2 and the second sealing valve seat 3 are sealed and fitted, and the first sealing valve seat 2 and the second sealing valve seat 3 are provided with valve balls 13 for sealing On the contact sealing surface, a first sealing elastic member 21 is provided between the first sealing valve seat 2 and the main valve body 1, and a se...

Embodiment 2

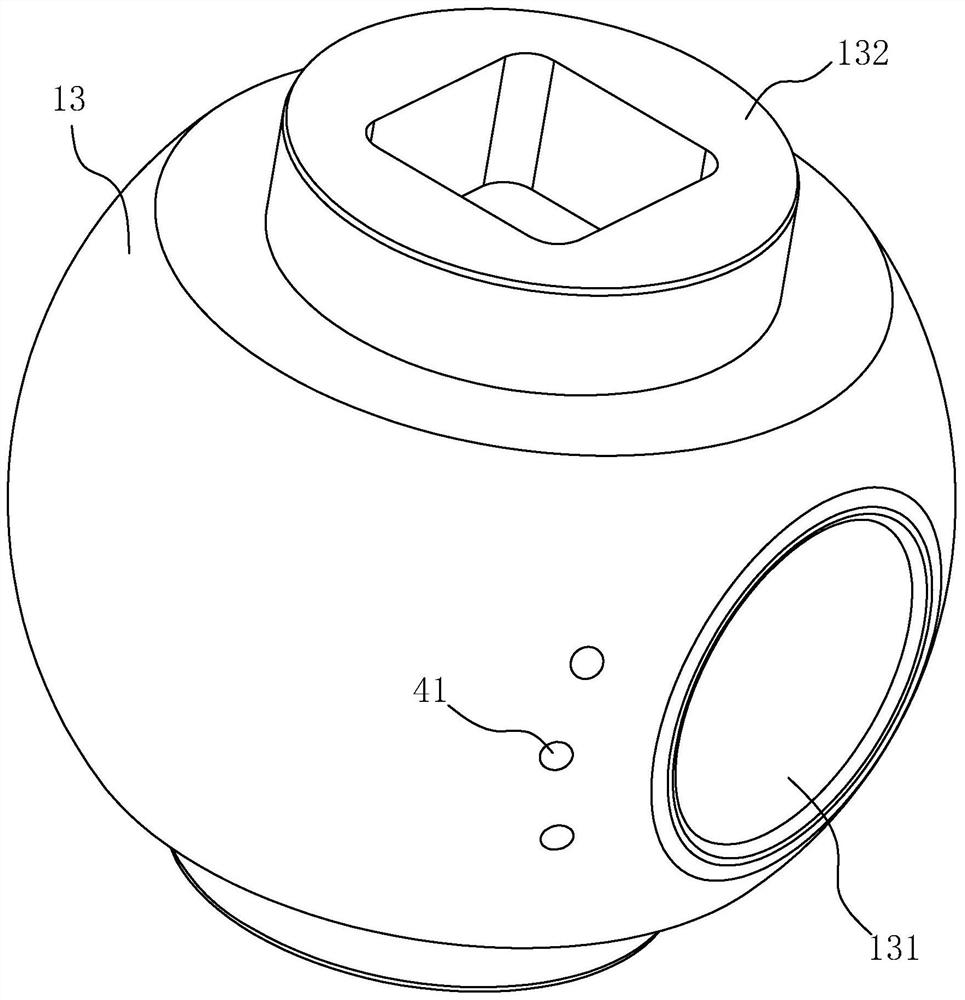

[0045] The difference between this embodiment and other embodiments is that in this embodiment: Figure 4 and Figure 5 As shown, the pressure relief structure 4 includes: a diversion hole 42 communicated with the installation chamber 12, and a number of pressure relief holes 41 arranged on one side of the diversion channel 131, the pressure relief hole 41 communicates with the diversion hole 42, In addition, in this embodiment, two sets of pressure relief holes 41 and diversion flow holes 42 are arranged in a centrally symmetrical manner, and each set of pressure relief holes 41 is provided with three sets, and the diversion channel 131 runs through the upper and lower ends of the valve ball 13; The pressure hole 41 guides the high-pressure medium into the guide flow hole 42 , and then the flow guide channel 131 releases the high pressure into the installation chamber 12 , thereby forming a pressure balance.

Embodiment 3

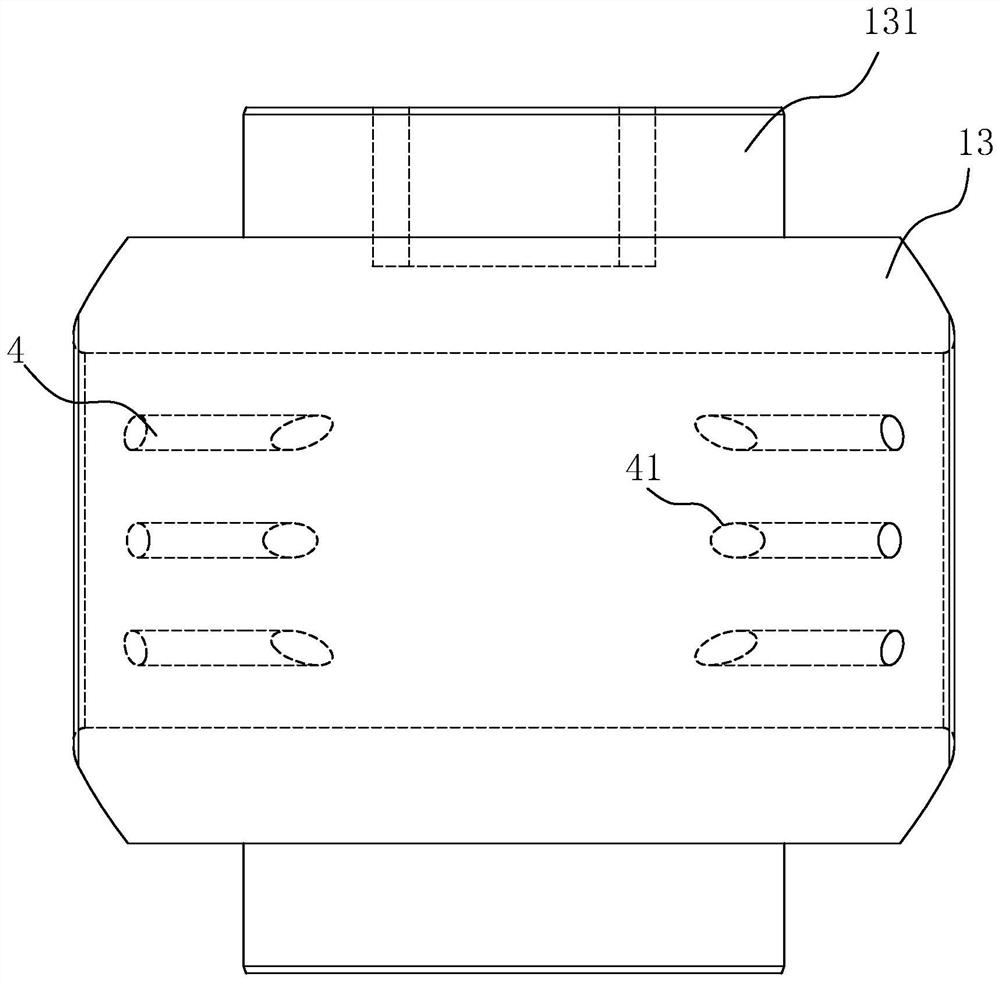

[0047] The difference between this embodiment and other embodiments is that in this embodiment: Figure 6 As shown, the pressure relief structure 4 includes: a guide hole 42 communicating with the installation chamber 12, and a number of pressure relief holes 41 arranged on one side of the flow guide channel 131. The pressure relief hole 41 is connected with the guide flow hole 42 and the flow guide The channel 131 is connected at the same time, and in this embodiment, two sets of pressure relief holes 41 and guide flow holes 42 are arranged in a centrally symmetrical manner, and each set of pressure relief holes 41 is provided with three sets, and the flow guide channel 131 runs through the upper and lower sides of the valve ball 13 Both ends; through the mutual cooperation of the pressure relief hole 41 and the guide flow hole 42, the high-pressure medium is introduced into the installation chamber 12 and the introduction channel at the same time, making the pressure balance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com