Reset mechanism and tubing protector adopting same

A reset mechanism and safety device technology, applied in the direction of weapon accessories, fuzes, offensive equipment, etc., can solve the problems of insurance failure, accidental opening of insurance, etc., and achieve the effect of improving reliability, reducing friction, and reducing the risk of jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

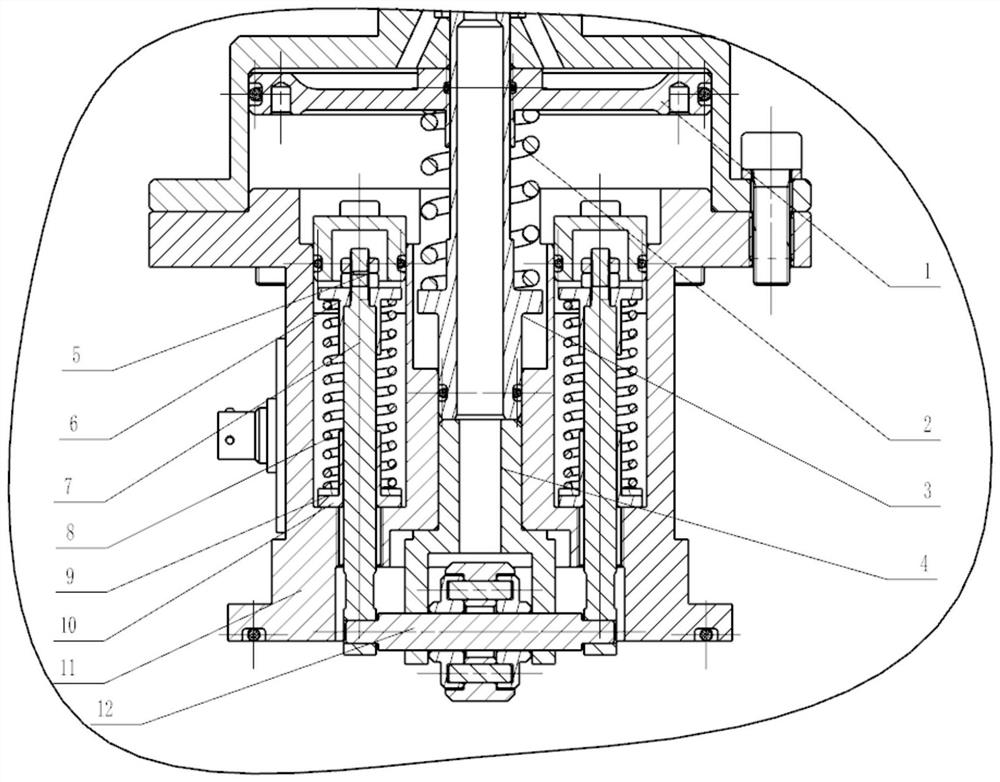

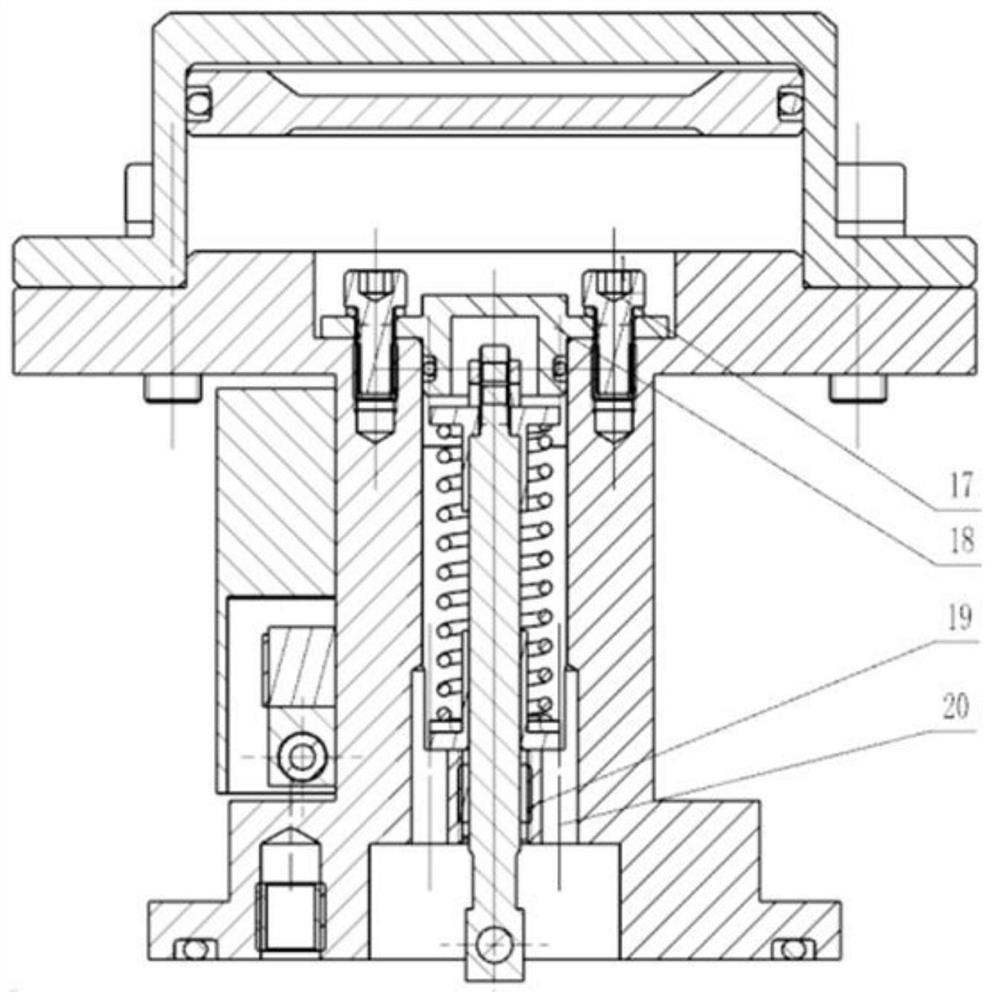

[0029] like Figure 1-Figure 3 As shown, a tube-mounted fuse equipped with a reset mechanism includes a housing, a base 11 , a piston 1 located in the housing, an energy storage compression spring 2 , an action pull rod 3 , and a reset mechanism located in the base 11 .

[0030] The base 11 provides the installation position for the reset mechanism through the lower end of the housing installed by bolts; There are O-ring seals between them.

[0031] The return mechanism includes two return pull rods 7 , two return springs 8 and a plug roller assembly 4 .

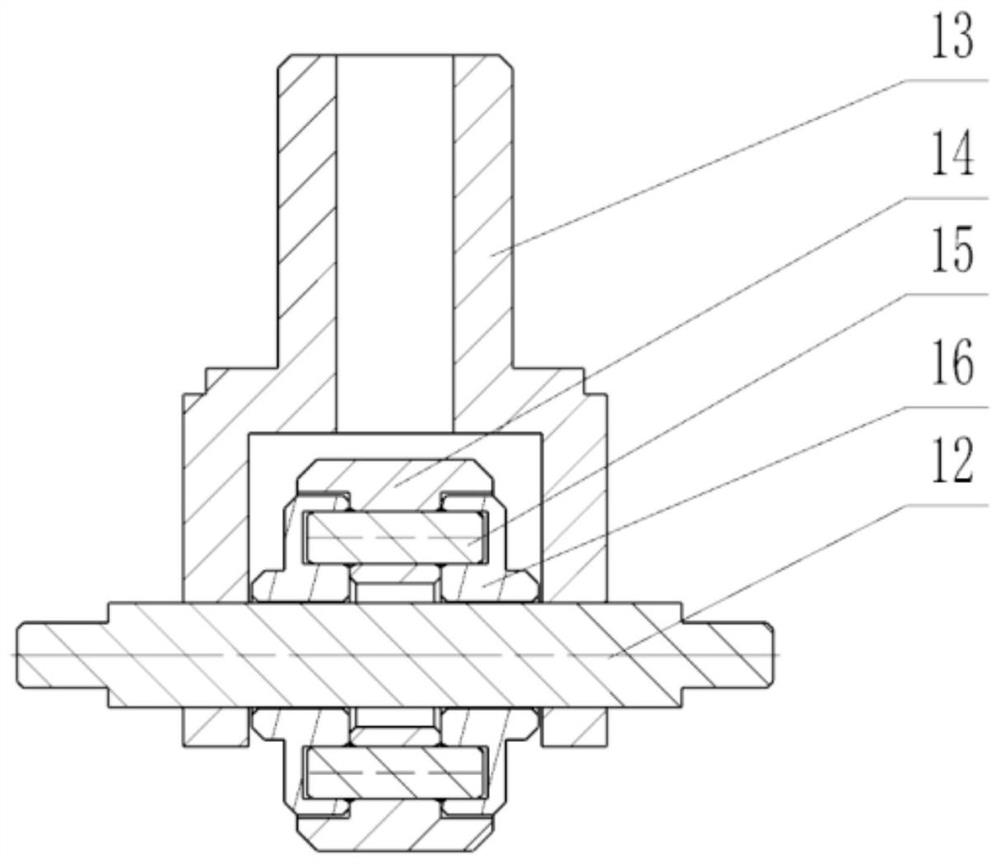

[0032]The plug roller assembly 4 includes a plug 13, a mandrel 12, a roller 14 and a roller auxiliary piece. The plug 13 is in an inverted Y shape, including a main rod and two support rods located at the lower end of the main rod; the upper end of the main rod is in contact with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com