Whole tube assembly tool for vacuum arc-extinguishing chamber

A vacuum interrupter and assembly tooling technology, applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of low assembly accuracy and low efficiency, and achieve the effect of ensuring locking accuracy and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

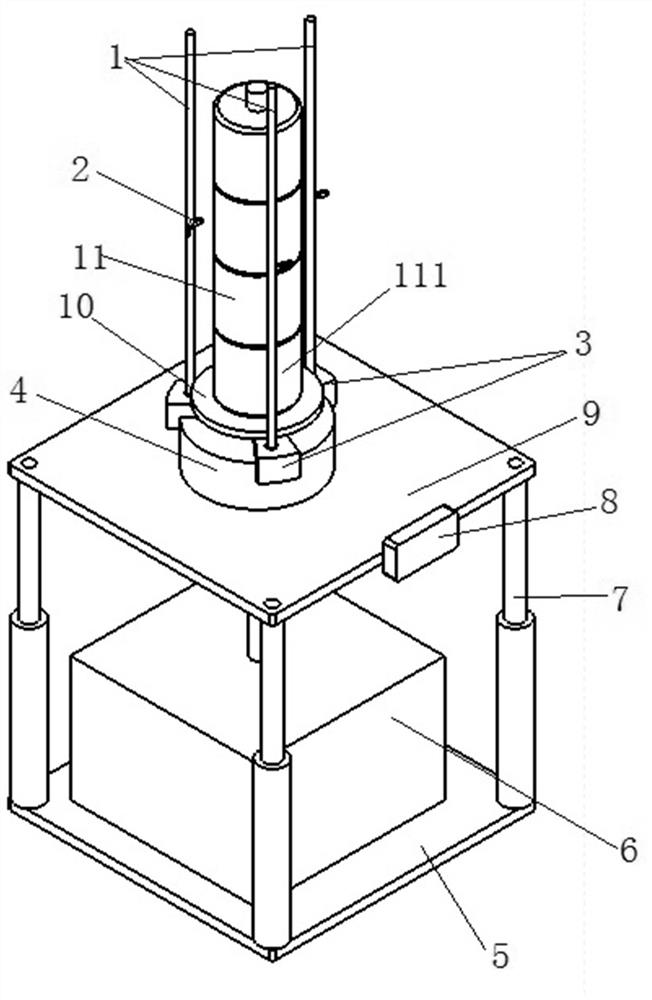

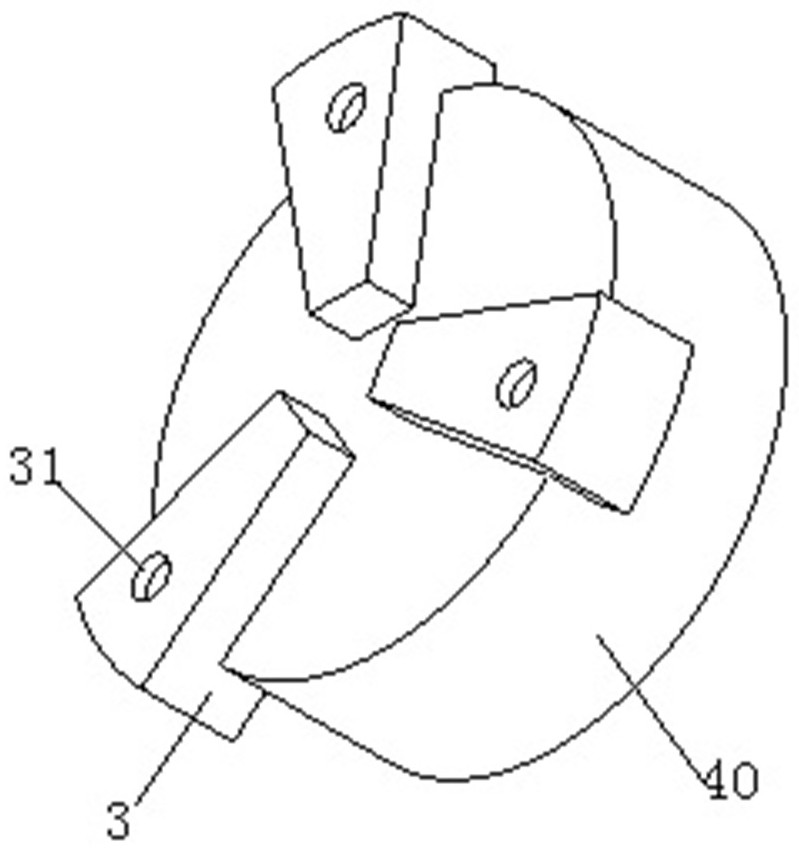

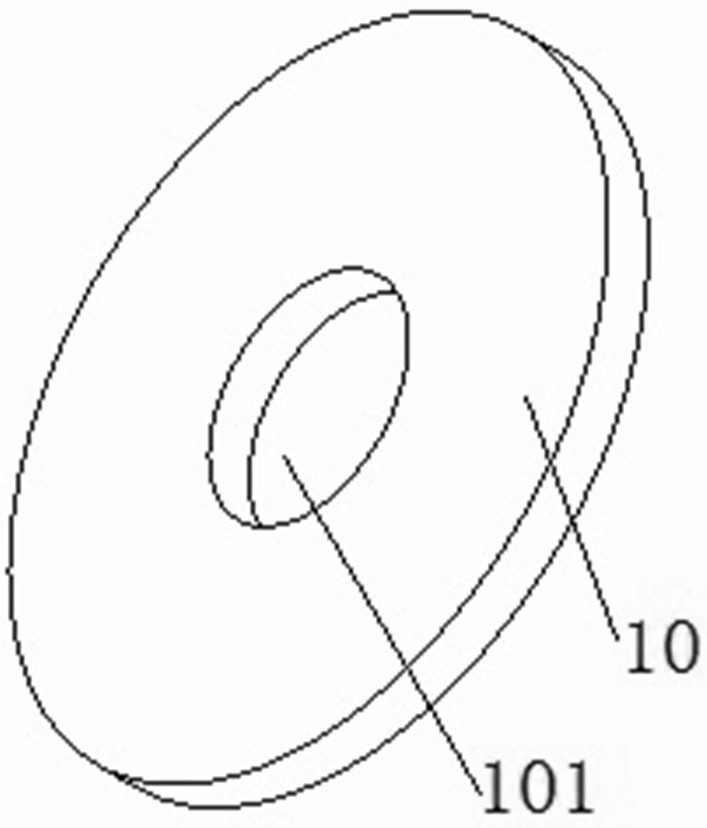

[0041] Such as Figure 1 to Figure 4As shown, the assembly tooling for the entire tube of the vacuum interrupter in this embodiment includes a lifting platform, which can move up and down vertically, and a chuck 4 is fixed on the lifting platform, and an assembly plate 10 is placed on the chuck 4. , used to support and place parts to assemble the vacuum interrupter 11, three centering shafts 1 are fixed on the chuck 4, the three centering shafts 1 extend vertically in parallel, and the three centering shafts 1 extend along the lifting platform The circumferential intervals are evenly distributed to form a positioning cylindrical surface, that is, on the same circumference, each centering shaft 1 is equipped with a centering piece 2 that is movable along a vertical guide, and the inner part of the centering piece 2 deviates from the centering shaft. There is a centering pressure head at the end. When assembling, first use the bottom porcelain shell 111 of the vacuum interrupter...

specific Embodiment 2

[0054] It differs from Embodiment 1 mainly in that: in Embodiment 1, three claws are arranged on the chuck. In this embodiment, four claws can be set on the chuck, and the four claws are evenly spaced along the circumferential direction of the chuck. Each claw is fixedly equipped with a centering shaft, and each centering shaft guides and moves respectively. Assembled with centering piece.

specific Embodiment 3

[0056] It differs from Embodiment 1 mainly in that: in Embodiment 1, the elastic member is a compression spring. In this embodiment, the elastic member can also be a tension spring. At this time, the sliding member can be designed as a chute, and the centering pressure head has a sliding section that fits and guides the chute. The radial dimension of the sliding section is relatively thick, so as to A stop step is formed, the above-mentioned extension spring is set on the centering pressure head, one end is hooked and connected with the hook structure provided on the corresponding end of the sliding section, and the other end is hooked and connected with the hook head at the corresponding end of the chute.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com