Electromechanical installation fault intelligent detection equipment

An intelligent detection and fault technology, which is applied in mechanical equipment, televisions, supporting machines, etc., can solve problems such as abnormal work, inconvenient detection, loose connection of equipment assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

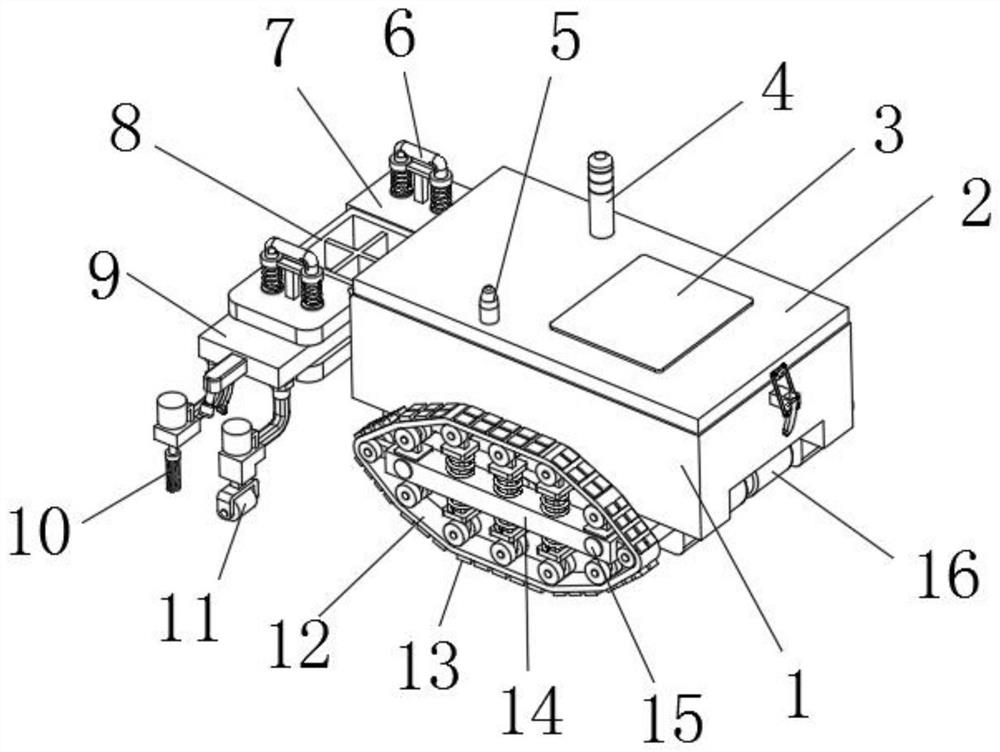

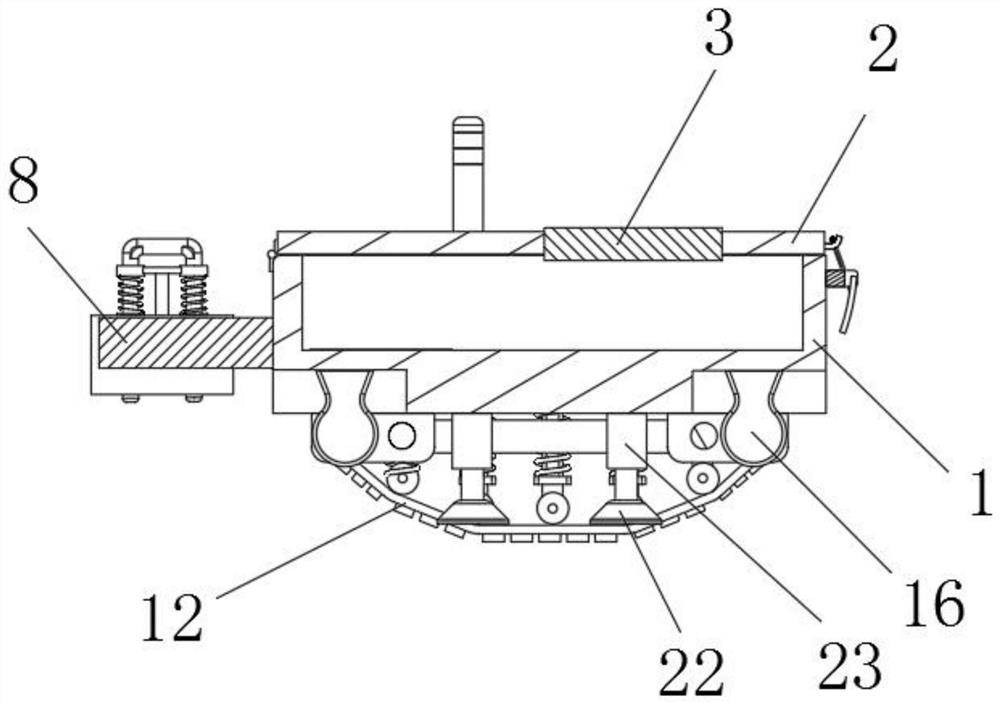

[0042] Example: Reference Figure 1-8 The shown intelligent detection equipment for electromechanical installation faults includes a body 1 .

[0043] The top side of the body 1 is rotatably equipped with an upper cover 2 through a hinge, and the upper cover 2 can be rotated to open, which is convenient for cleaning and maintaining the inside of the body 1 .

[0044] A control panel 3 and a signal receiver 5 are fixedly installed on the top side of the upper cover 2. The signal receiver 5 is arranged to receive signals transmitted by the remote controller and transmit them to the control panel 3 to guide the body 1 to move.

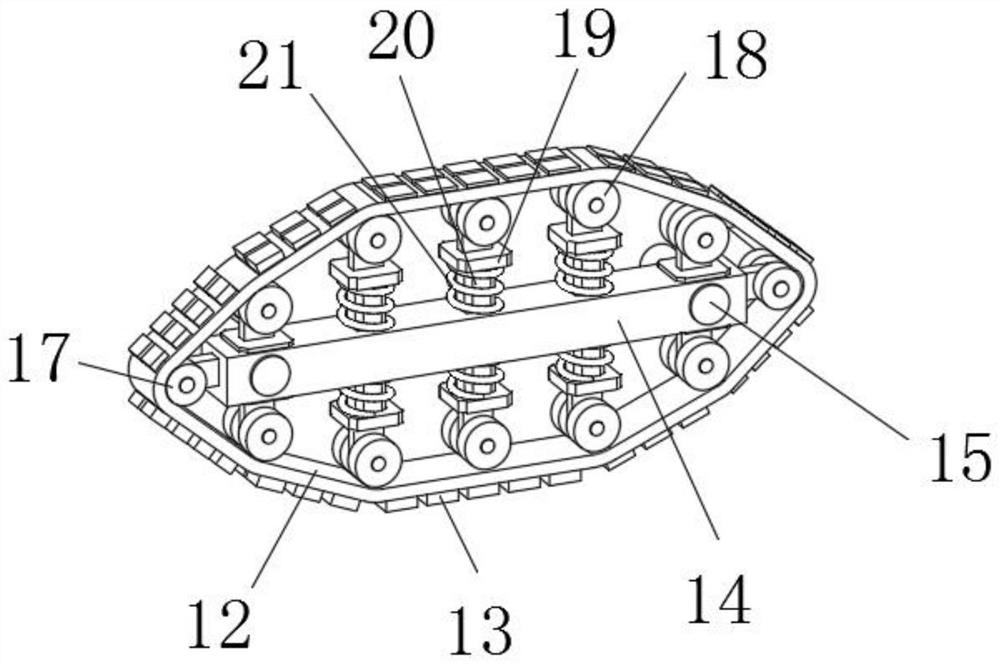

[0045] The bottom side of the body 1 is fixedly installed with two fixed crossbeams 14 through a plurality of fixed rods 15, and a plurality of sliding holes are evenly opened on the two fixed crossbeams 14, and a first square sliding column 20 is correspondingly slidably installed respectively. Both ends of the first square sliding column 20 are rotatab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com