Self-adaptive seedling feeding control system and method for plug seedling transplanter

A control system and self-adaptive technology, applied in planting methods, transplanting machinery, applications, etc., can solve problems such as low seedling feeding efficiency, fatigue, missed planting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

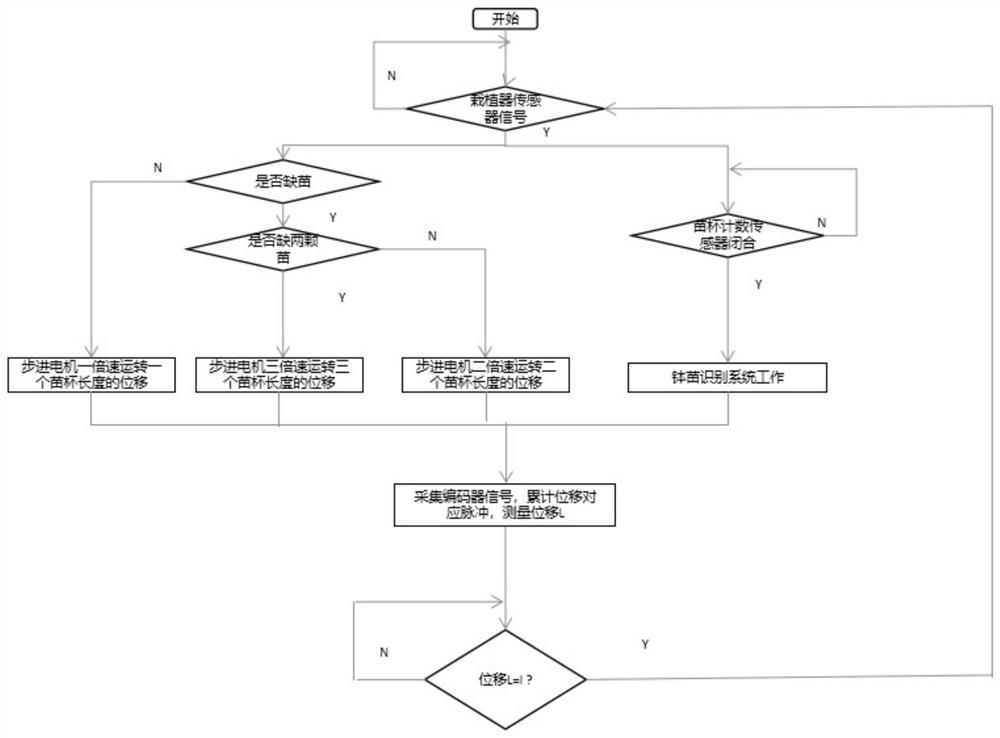

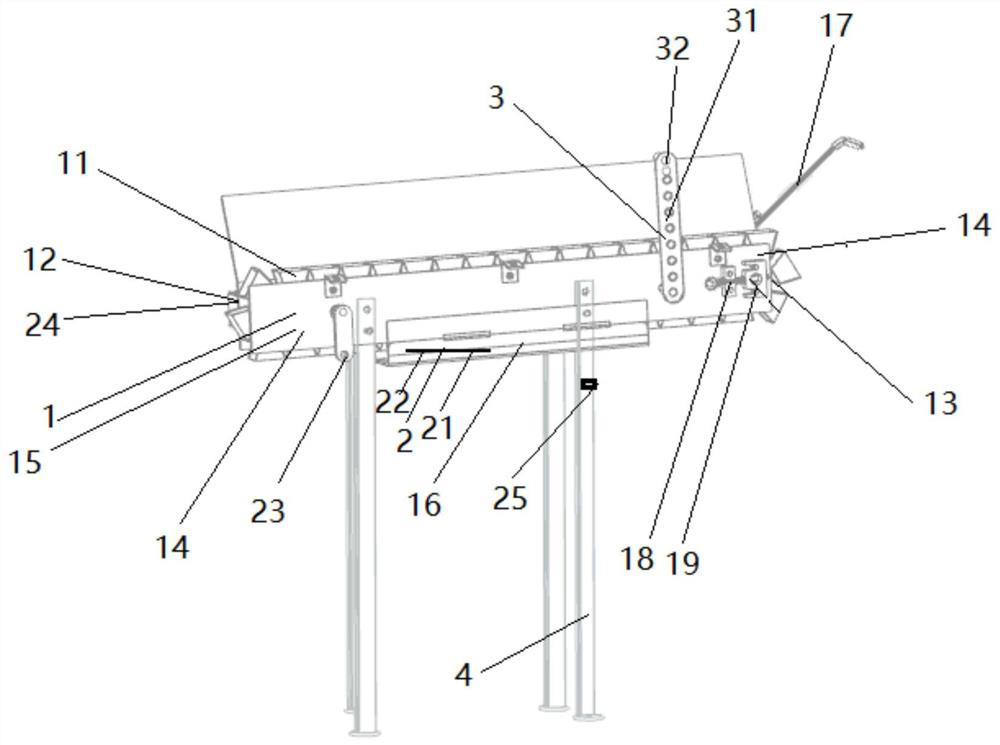

[0018] figure 1 It is a control block diagram of a self-adaptive seedling feeding control system and method for a plug seedling transplanter of the present invention. First, take out the plug seedlings and put them into the seedling separation cup 11 of the seedling feeding mechanism at an appropriate time. When the planter position detection sensor 25. When it is detected that the planter has risen to the seedling feeding position, the control system starts to work, and the seedling separation cup 11, driven by the stepping motor 12, passes through the pot seedling detection system 3 and the seedling cup counting sensor 23 successively to determine whether there is a lack of seedlings in the seedling separation cup And the number of seedling cups that are missing at the same time, when there are zero seedling cups, the stepper motor runs at double speed with the given pulse number, and the stepping motor rotates one seedling cup at this time; when the number of continuous seed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com