Waste residue filtering equipment for sewage treatment

A technology of sewage treatment and filtration equipment, applied in the direction of filtration separation, filtration loop, fixed filter element filter, etc., can solve the problem that sewage waste is not easy to filter and remove, and achieve the effect of reducing work intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

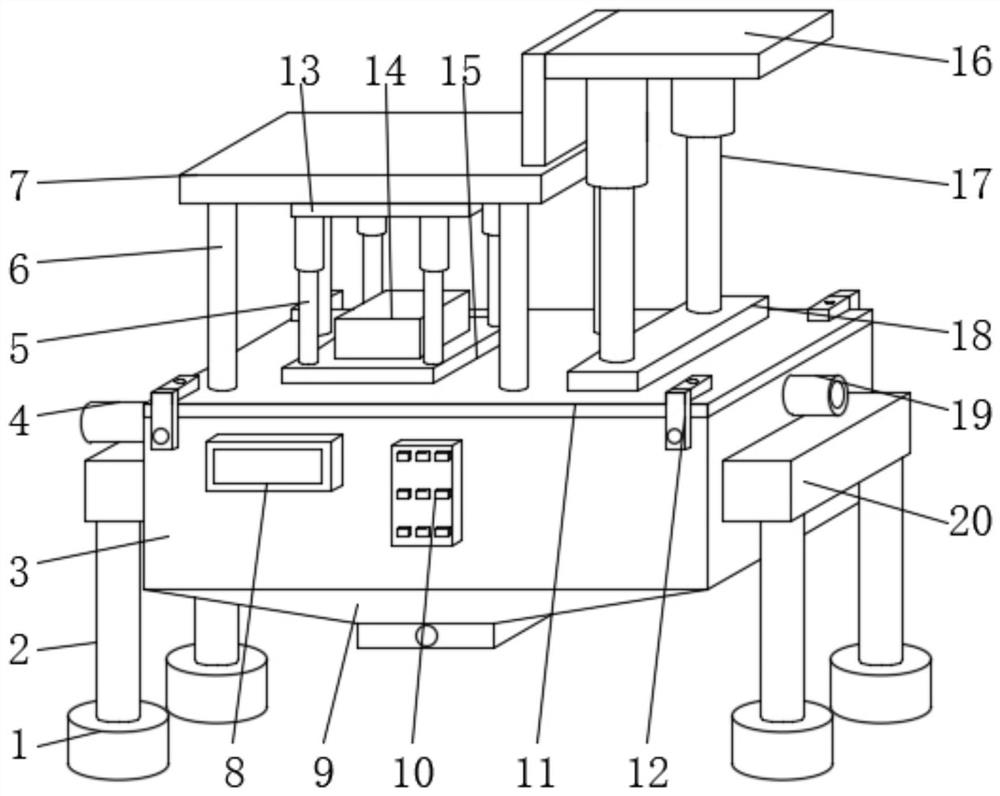

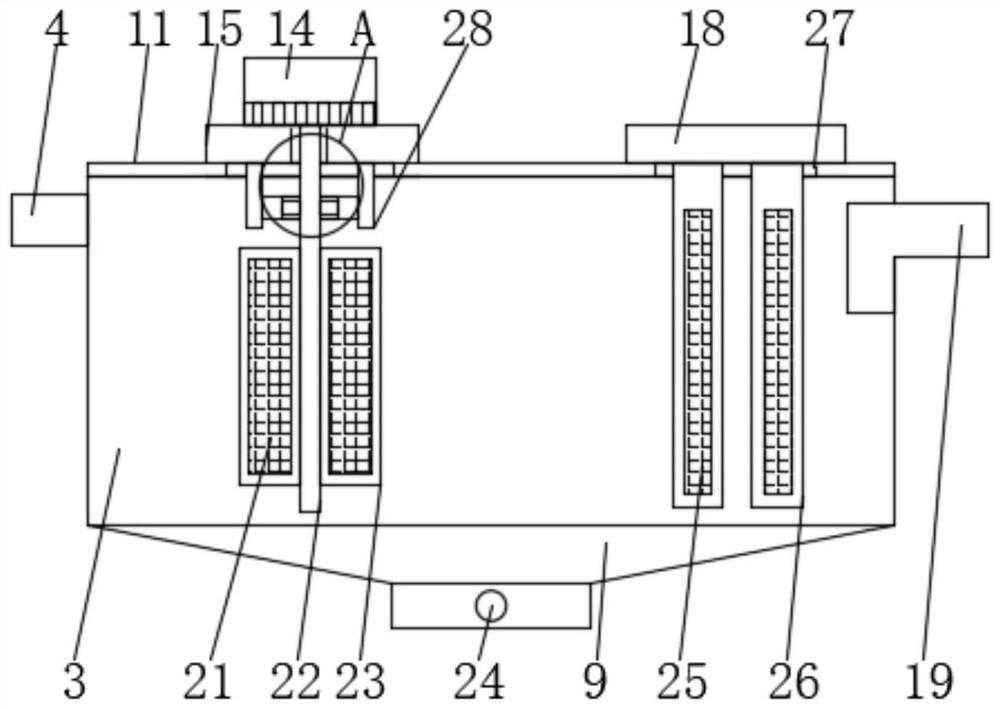

[0033] Such as Figure 1-4 As shown, the embodiment of the present invention provides a waste residue filtering device for sewage treatment, including a box body 3, the upper end of the box body 3 is provided with a cover plate 11, and the left side of the middle part of the upper end of the cover plate 11 is provided with a second port 31, On the left side of the upper end of the cover plate 11 and with respect to the surroundings of the second port 31, a support rod 6 is fixedly connected, the upper end of the support rod 6 is fixedly connected with a support plate 7, and a first electric pusher is arranged around the lower end of the support plate 7. Rod 5, the side of the first electric push rod 5 is fixedly connected with a fixed block 13, the upper end of the fixed block 13 is connected with the lower end of the support plate 7, and the lower end of the first electric push rod 5 is fixedly connected with the second port 31 There is a first sealing plate 15 to adjust the ...

Embodiment 2

[0037] The difference between this embodiment and the first embodiment is that the first electric push rod 5 and the second electric push rod 17 can be replaced with air cylinders, so that the first sealing plate 15 and the second sealing plate can be adjusted in a pneumatic way. 18' use height for adjustable use.

Embodiment 3

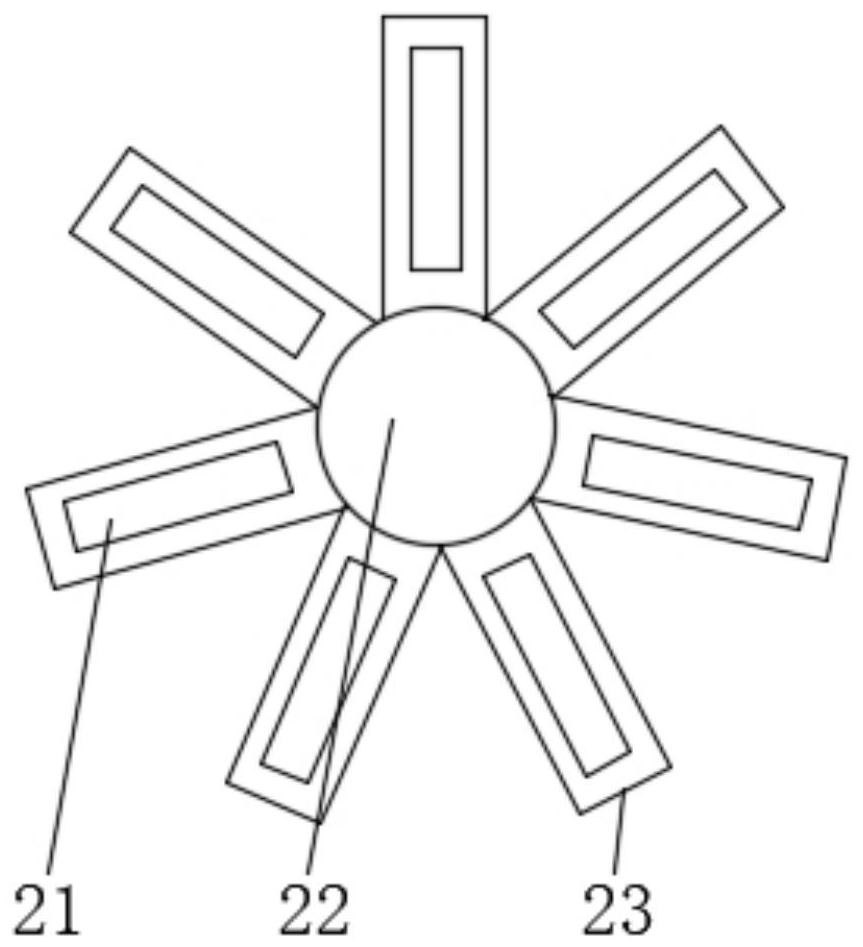

[0039] The difference between this embodiment and the first embodiment is that the U-shaped block 28 is replaced by a sleeve, and the middle part of the sleeve is provided with a rotating hole 29, and the upper end of the sleeve and the outer end of the rotating hole 29 are connected to the first sealing plate 15. Fixedly connected, the rotating rod 22 penetrates the sleeve, and the inner wall of the sleeve is fixedly connected with a buffer pad 30 relative to the outer surface of the rotating rod 22. The buffer pad 30 is used to buffer the rotating rod 22 without affecting the rotation of the rotating rod 22. In use, the sleeve can extend the buffer protection distance of the rotating rod 22, thereby reducing the degree of shaking of the rotating rod 22.

[0040] Working principle: U-shaped tubes 9 are deposited at the lower end of the box body 3 to effectively collect the depositable waste residue, and the use height of the first sealing plate 15 is adjusted by the first elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com