Automatic welding machine based on machine vision and control method thereof

An automatic welding machine and machine vision technology, applied in manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of long time consumption and poor real-time monitoring of welding quality, and achieve the effect of improving real-time performance and capturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

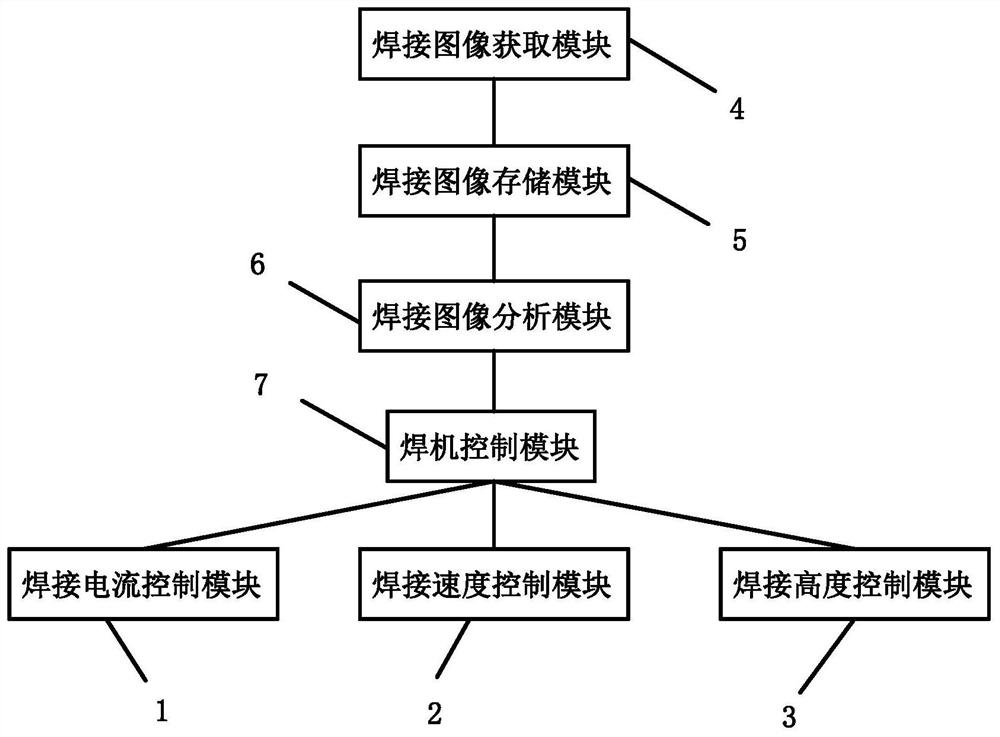

[0034] refer to figure 1 , a specific embodiment of the present invention includes,

[0035] Welding current control module 1, used to control welding current;

[0036] The welding speed control module 2 is used to control the welding speed;

[0037] The welding torch height control module 3 is used to control the length of the welding arc;

[0038] Weld seam image acquisition module 4, is used for taking weld seam image;

[0039] The weld image storage module 5 is used to prestore the standard weld image and store the image captured by the weld image acquisition module 4;

[0040] The weld image analysis module 6 is used to analyze the weld image captured by the weld image acquisition module 4;

[0041] The welding machine control module 7 communicates with the welding current control module 1 , the welding speed control module 2 and the welding torch height control module 3 , and is used to control the welding parameters according to the analysis results of the weld seam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com