Flexible belt dismounting device

A technology for dismantling devices and belts, which is applied in the direction of hand-held tools and manufacturing tools, can solve problems such as work-related accidents, time-consuming and labor-intensive belt disassembly, and achieve the effects of avoiding disability, reducing weight, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

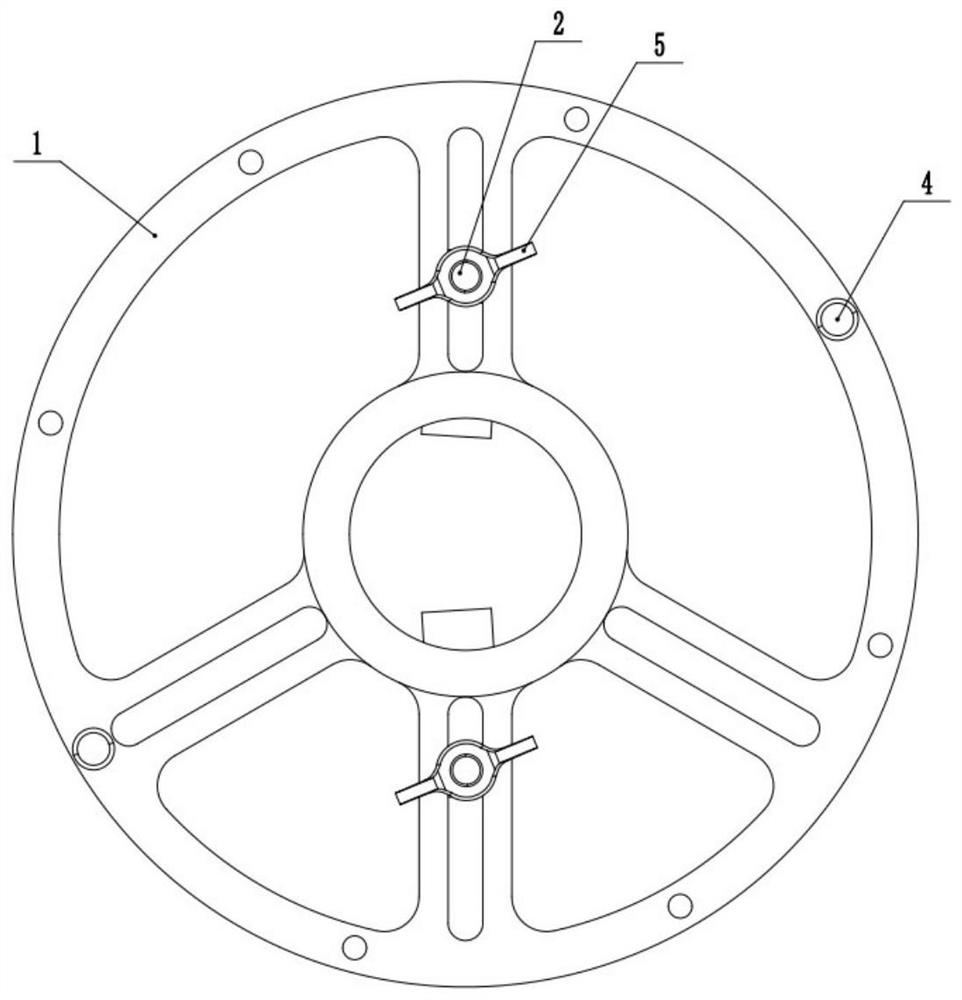

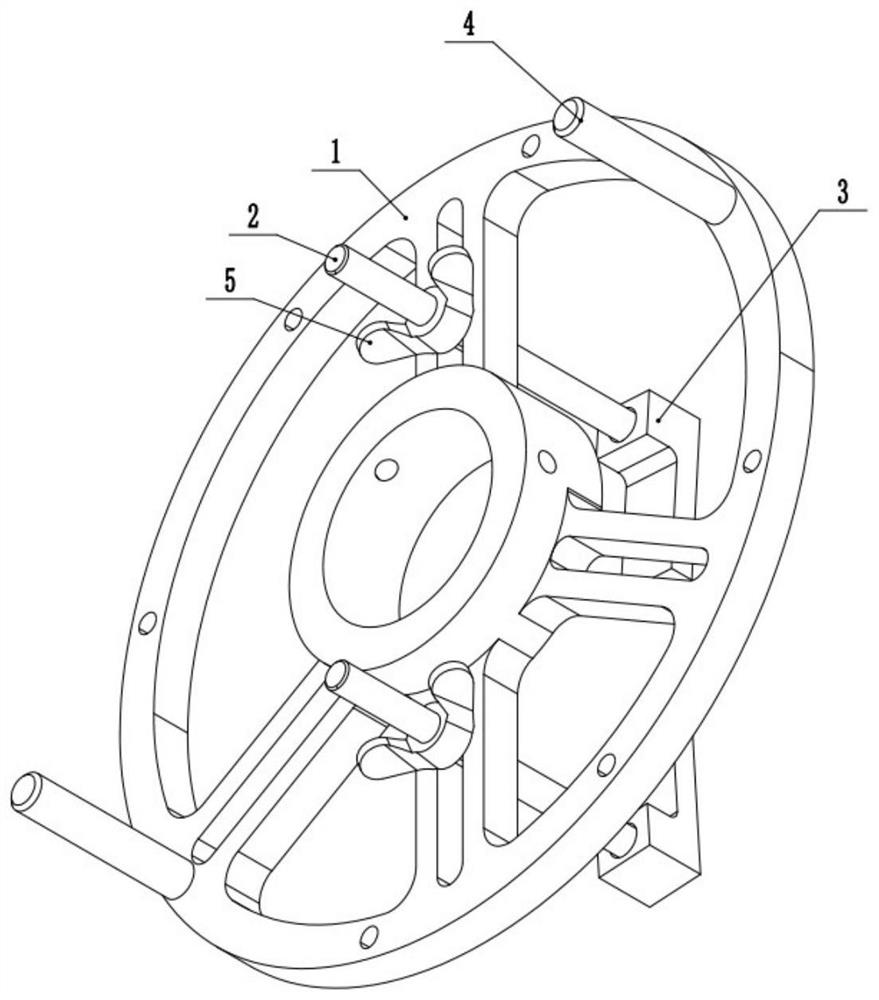

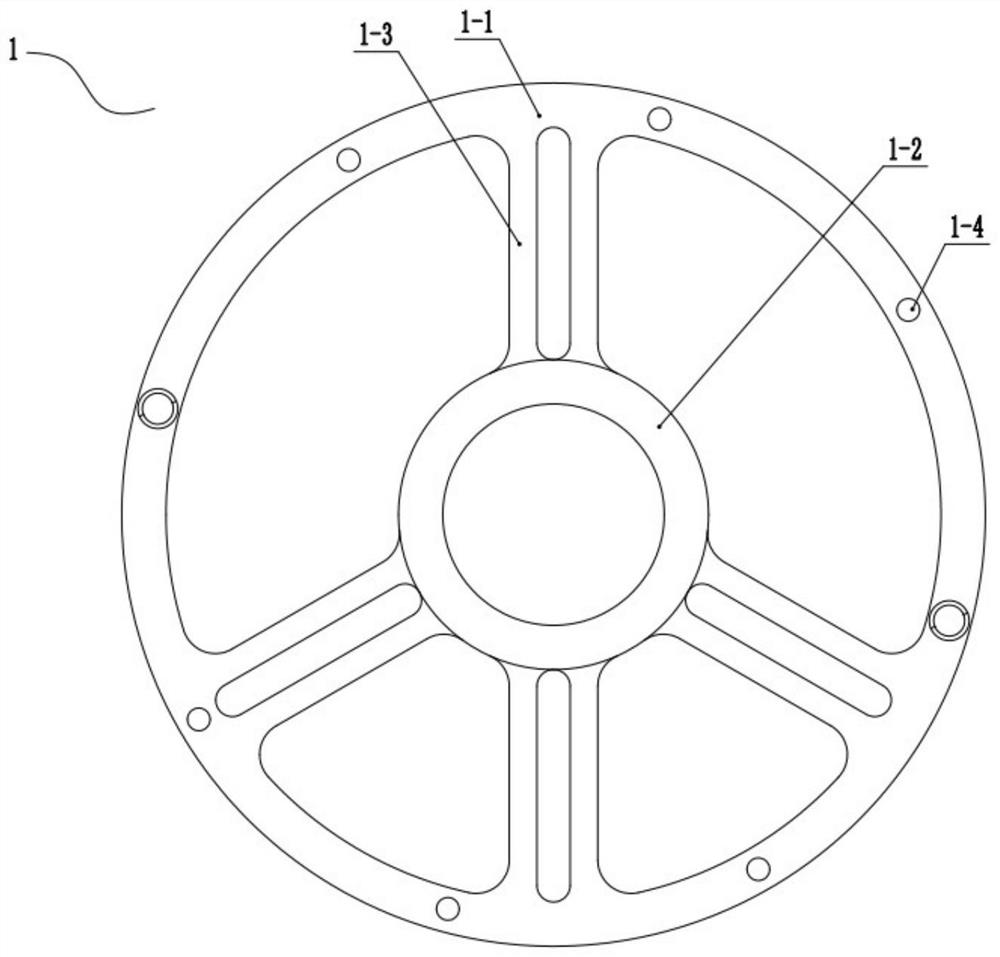

[0036] refer to Figure 1 to Figure 5 , a flexible belt removal device, including a runner body 1 and a tension rod 2, the runner body 1 includes an outer rim 1-1 and an inner rim 1-2, and the outer rim 1-1 and the inner rim There are several ribs 1-3 arranged in the circumferential direction between 1-2, an operating rod 4 is installed on the outer rim 1-1, an installation groove is arranged on the ribs 1-3, and the tension rod 2 is inserted into the installation groove, and one end of the tension rod 2 is provided with a fastener 5, and the other end is provided with a tension plate 3.

[0037] The installation groove is elongated, the length of the installation groove ranges from R65mm to R180mm, and the width of the installation groove matches the tension rod 2 . According to the size of the rib plate of the pulley, the position of the tension rod 2 in the installation groove can be adjusted, so that the tension plate 3 can be smoothly fixed on the rib plate of the pulley...

Embodiment 2

[0050]refer to Figure 6 and Figure 7 , is different from Embodiment 1 in the structure connected with the pulley, and the rest are the same as Embodiment 1.

[0051] The tension rod 2 is removed, and a shaft sleeve 6 is placed in the inner rim 1-2, a keyway 6-1 is provided on the inner side wall of the shaft sleeve 6, and a keyway 6-1 is provided on the outer side wall of the shaft sleeve 6. There is a groove 6-2, and the inner rim 1-2 is provided with a fixing hole corresponding to the groove 6-2, and the fixing hole is used to accommodate the top wire 8.

[0052] A positioning hole 6-3 is provided on the side wall of the shaft sleeve 6, and a positioning member is provided in the positioning hole 6-3.

[0053] Optionally, the positioning member may be a bolt or a screw.

[0054] There are three grooves 6 - 2 , and the three grooves 6 - 2 are evenly distributed on the outer wall of the sleeve 6 in the circumferential direction, and the grooves 6 - 2 extend along the leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com