Precast beam maintenance spraying device for civil construction

A spray device and a technology for prefabricated beams, which are used in manufacturing tools, water/sludge/sewage treatment, ceramic molding machines, etc., can solve problems such as insufficient spraying of prefabricated beams, and achieve enhanced practicability, avoid pollution, and avoid bumps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

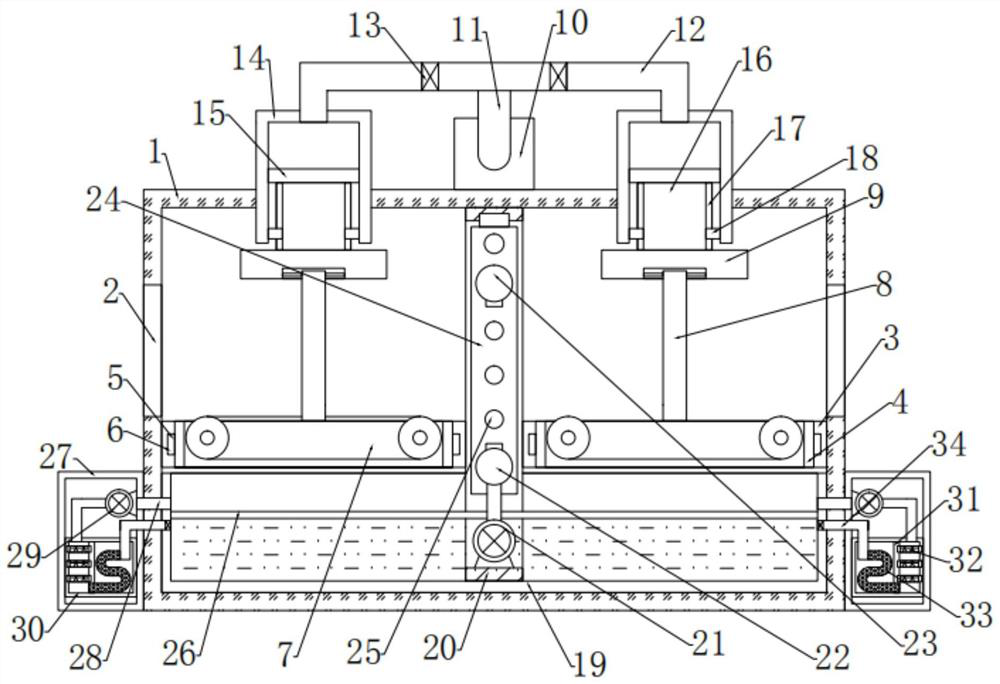

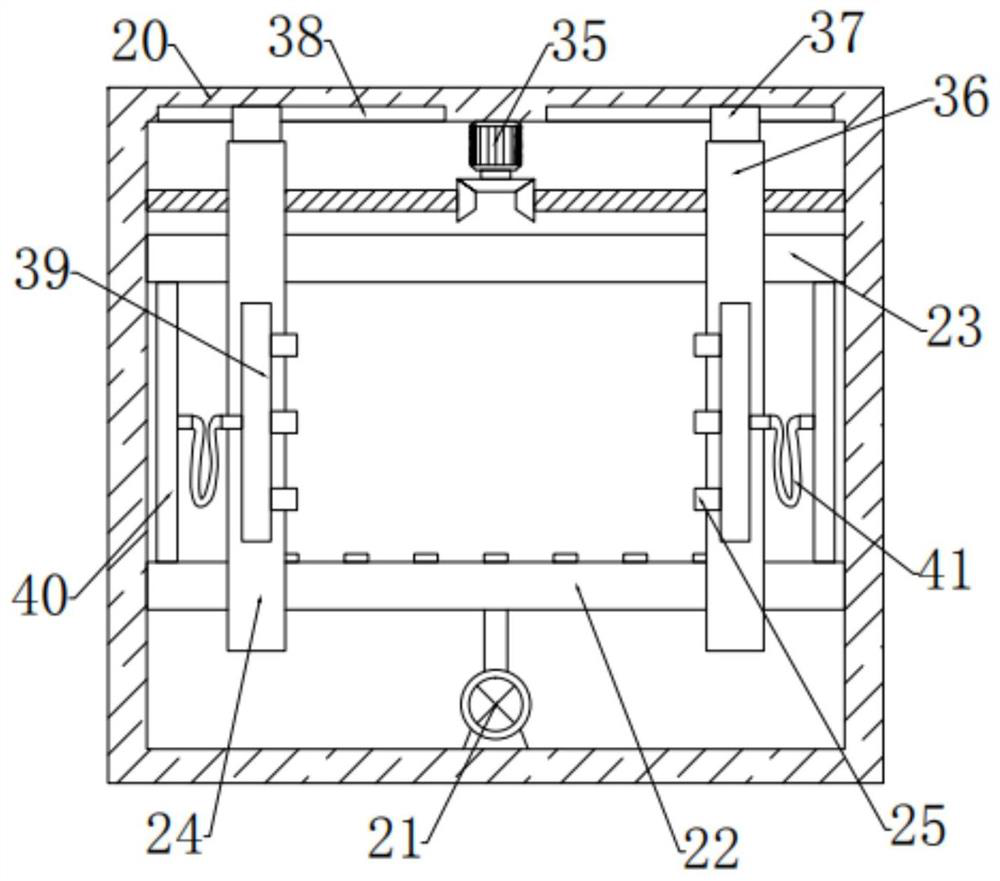

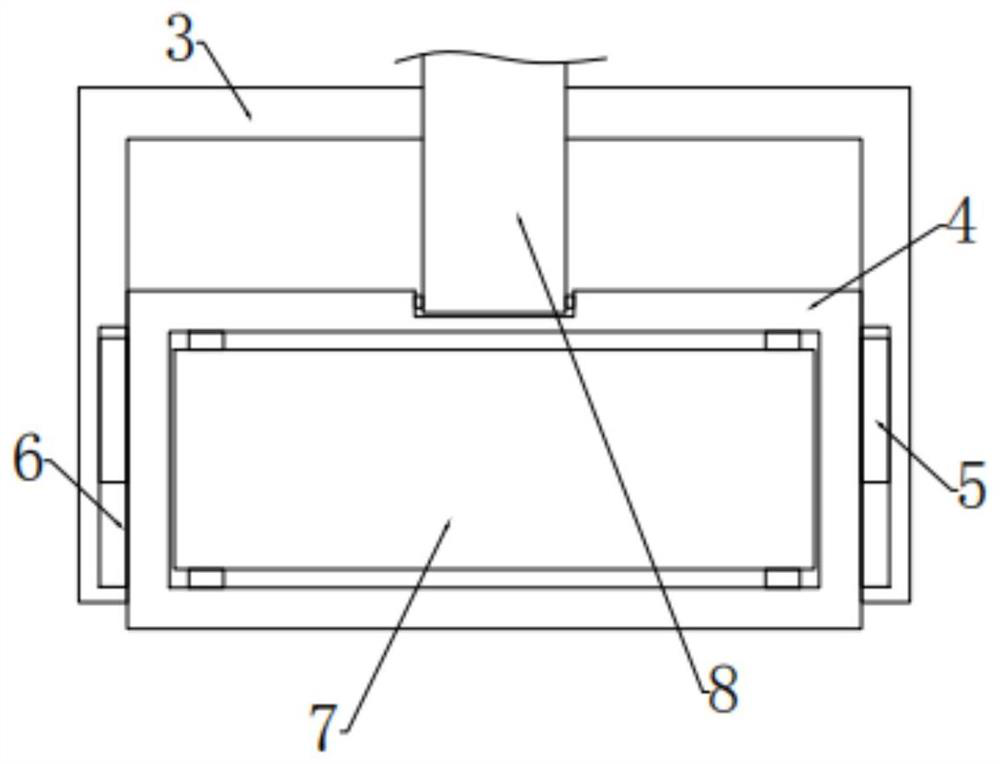

[0025] see Figure 1-4 , in an embodiment of the present invention, a prefabricated beam maintenance spray device for civil engineering construction, including a housing 1, the left and right sides of the housing 1 are provided with openings 2 for the entry and exit of prefabricated beams, and the inner bottom of the housing 1 The fixed connection is provided with a water tank 19, and the upper side of the water tank 19 is provided with a spraying mechanism, and the left and right sides of the spraying mechanism are all provided with conveying mechanisms.

Embodiment 2

[0027] In this embodiment, the spraying mechanism includes a support frame 20 fixedly connected to the top of the inner side of the water tank 19, and the bottom of the inner side of the support frame 20 is bolt-connected with a first water pump 21, and the upper side of the first water pump 21 is provided with a The first shower pipe 22 fixedly connected to the support frame 20 is connected to the output end of the first water pump 21 through a conduit. The upper side of the first shower pipe 22 is provided with a The second spray pipe 23 that is fixedly connected, the water guide pipe 40 is fixedly connected between the front and rear ends of the first spray pipe 22 and the second spray pipe 23, and the first spray pipe 22 is connected to the second spray pipe 23. The outer sides of the front and rear ends of the spray pipe 23 are slidably connected to be provided with a spray plate 24. The spray plate 24 is connected to the driving mechanism arranged on the upper side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com