Long dropper forming die

A tube forming and mold technology, which is applied to household appliances, tubular items, other household appliances, etc., can solve the problems of prolonged production cycle and long cooling time, so as to strengthen turbulence intensity, improve production efficiency, and ensure cooling cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] refer to Figure 1 to Figure 3 Embodiments of the present invention will be further described.

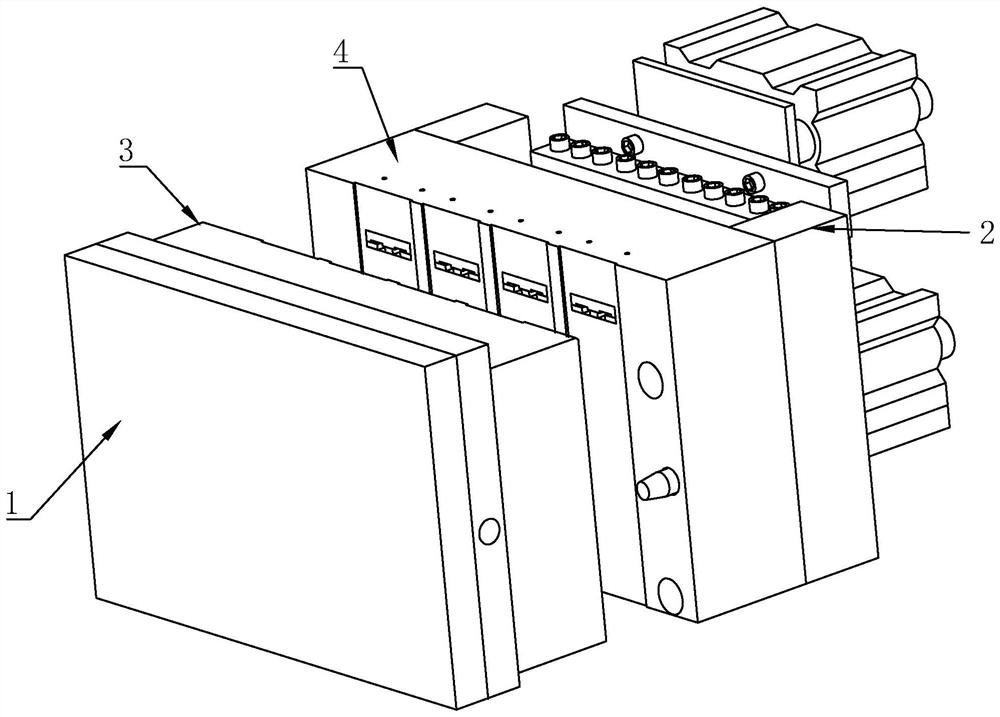

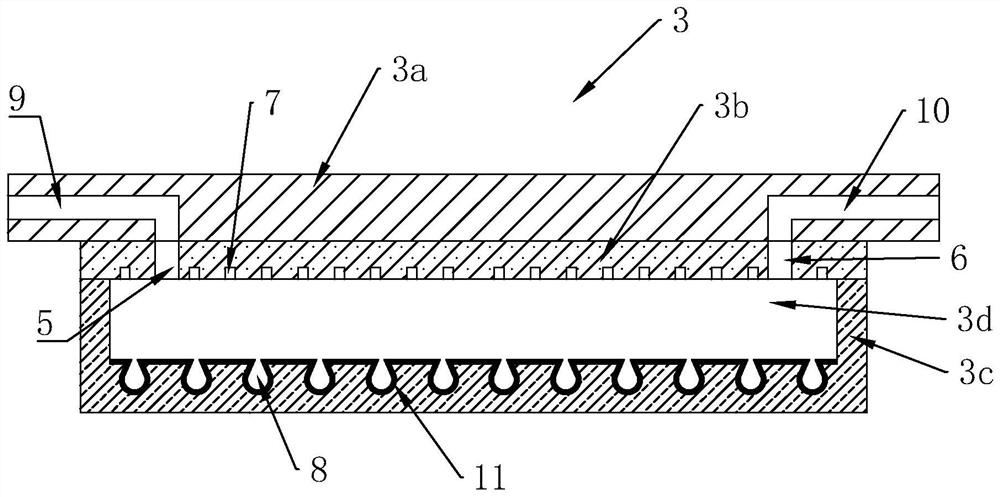

[0022] A long dropper forming mold, comprising an upper mold frame 1, a lower mold frame 2, an upper mold plate 3 and a lower mold plate 4, an upper mold cavity is formed on the end surface of the upper mold plate 3, and a lower mold cavity is formed on an end surface of the lower mold plate 4, The upper template 3 includes an upper fixed plate 3a arranged in sequence, a cooling cover plate 3b and a lower support plate 3c, a cooling chamber 3d is formed on one end surface of the lower support plate 3c, and the cooling cover plate 3b seals the lower support plate 3c The opening of the upper cooling chamber 3d, the cooling cover plate 3b is provided with an inlet port 65 and an outlet port communicating with the cooling chamber 3d, and the bottom of the cooling chamber 3d is provided with a number of evenly distributed first flow channel grooves 7 A second runner groove 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com