Extraction device of alumite and gilding press comprising extraction device

A extraction device, anodized aluminum technology, applied in printing presses, rotary printing machines, transportation and packaging, etc., can solve the problems of inconvenient operation and achieve the effect of simplifying the process of extraction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

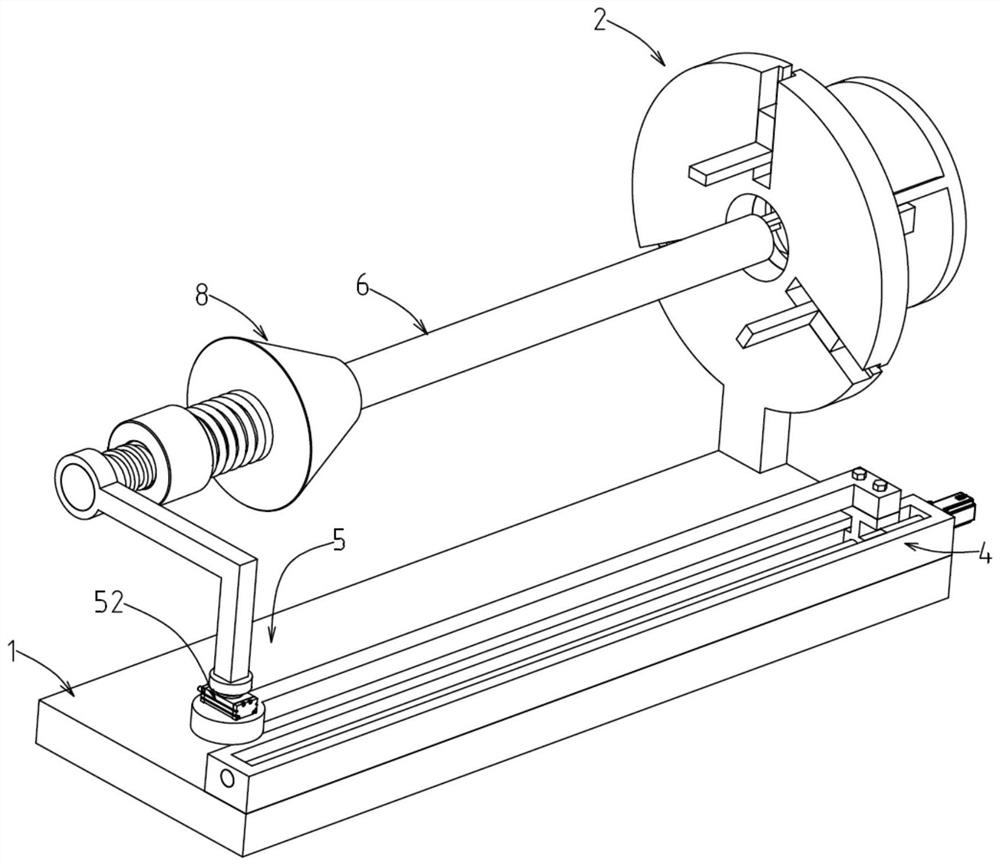

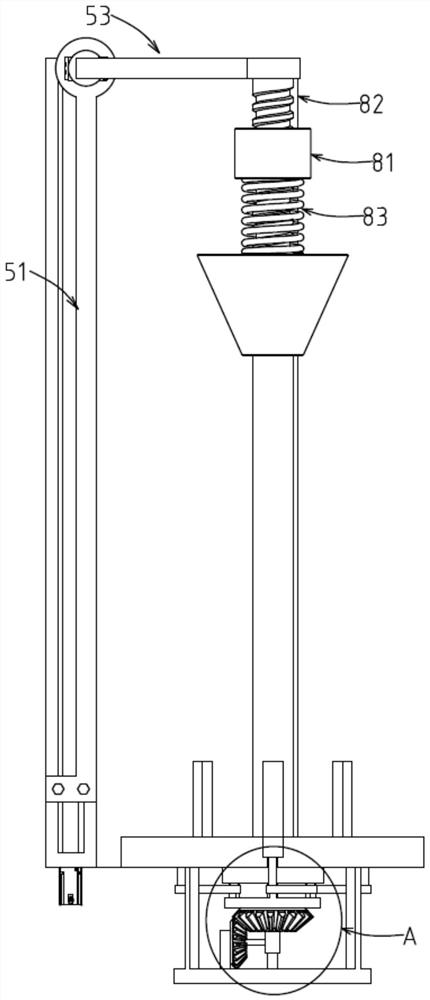

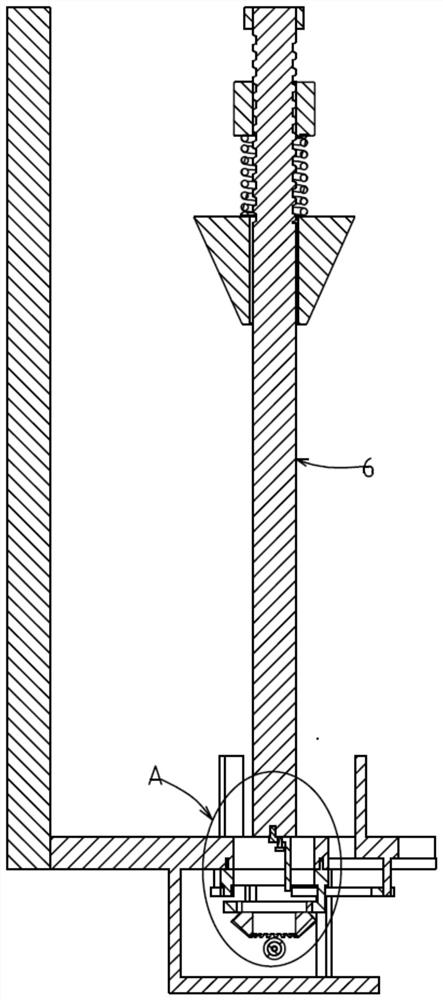

[0026] see Figure 1 to Figure 6 , the present invention provides a technical solution:

[0027] An extraction device for anodized aluminum, comprising a support plate 1, a three-jaw chuck assembly 2, a transmission assembly 3, a linear drive mechanism 4, a connecting rod assembly 5, a drawer rod 6, an L-shaped friction plate 7, and a cone barrel 8, wherein:

[0028] Three-jaw chuck assembly 2 is arranged on the end of support plate 1, and three-jaw chuck assembly 2 comprises chuck 21, jaw 22, rotating disk 23 and connecting arm 24, and chuck 21 is fixedly installed on support plate 1, three The jaws 22 are respectively movably installed in three guide grooves on the chuck 21, and the turntable 23 is rotatably mounted on the chuck 21. The jaws 22 are connected with the turntable 23 through the connecting arm 24, wherein the two ends of the connecting arm 24 are connected to the claws. 22 and the rotating disk 23 are hinged;

[0029] Transmission assembly 3 includes bevel gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com